One-way Stretch Plastic Geogrid

Using polymer and nano-scale carbon black as the main raw materials the unidirectional mesh uniforr

grille products are produced through extrusion and traction process.

1. Slow down reflective cracks

2. Anti-fatigue cracking

3. High temperature rut resistance

4. Resistant to low temperature shrinkage cracking

Product specifications: TGDG35,TGDG50,TGDG80, TGDG120,TGDG160.TGDG260,TGDG300. etc., Width 1~3meters.

Features:

1. Enhance the roadbed, improve the stability and bearing capacity, and withstand greater alternating loads

2 Prevent roadbed deformation and cracking caused by the loss of roadbed materials!

3. The filling capacity of the filling behind the retaining wall can be improved. and the engineering cost can be saved.

Application : lt is suitable for roadbed reinforcement such as highways, municipal roads, railways, and airstrips; dams forrivers and seas are strengthened; fences for orchards, vegetable plots, livestock, land, etc. are applicable to highways, municipalroads. railways. and airplanes. Reinforcement of the reinforced earth retaining wall of the runway and river dam.

Product Implementation Standards:

One-way Stretch Plastic Geogrid GB/T17689-1999 | |||||||||||||

Item | Specification | ||||||||||||

TGDG25 | TGDG35 | TGDG50 | TGDG80 | TGDG110 | TGDG150 | TGDG170 | TGDG200 | TGDG220 | TGDG240 | TGDG260 | TGDG280 | TGDG300 | |

Tensile strength KN/m≥ | 25 | 35 | 50 | 80 | 110 | 150 | 170 | 200 | 220 | 240 | 260 | 280 | 300 |

Standard elongation %≤ | 10.0 | ||||||||||||

Tensile strength at 2% elongation KN/m≥ | 6 | 10 | 12 | 26 | 30 | 39 | 45 | 56 | 59 | 65 | 78 | 84.5 | 90 |

Tensile strength at 5% elongation KN/m≥ | 12 | 22 | 28 | 48 | 60 | 77 | 90 | 112 | 120 | 132 | 157 | 170 | 182 |

Creep Ultimate Strength KN/m≥ | 11 | 15 | 21 | 30.2 | 41 | 49 | 57 | 64 | 71.5 | 79 | 86 | 91.5 | 100 |

Width (m) | 1~3 | ||||||||||||

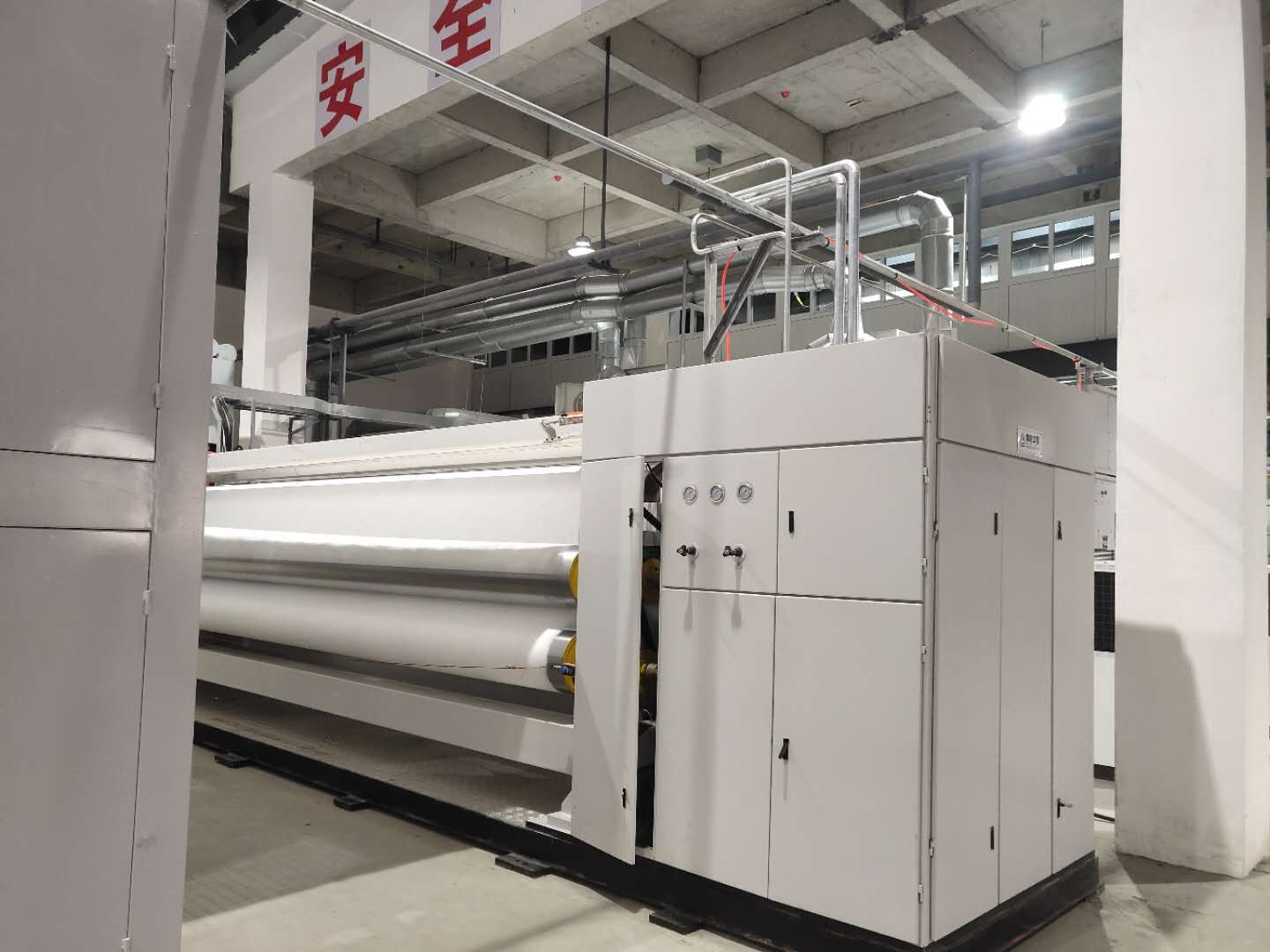

Equipment of One-way Stretch Plastic Geogrid

Packing of One-way Stretch Plastic Geogrid

Construction of One-way Stretch Plastic Geogrid

One-way Stretch Plastic Geogrid GB/T17689-1999 | |||||||||||||

Item | Specification | ||||||||||||

TGDG25 | TGDG35 | TGDG50 | TGDG80 | TGDG110 | TGDG150 | TGDG170 | TGDG200 | TGDG220 | TGDG240 | TGDG260 | TGDG280 | TGDG300 | |

Tensile strength KN/m≥ | 25 | 35 | 50 | 80 | 110 | 150 | 170 | 200 | 220 | 240 | 260 | 280 | 300 |

Standard elongation %≤ | 10.0 | ||||||||||||

Tensile strength at 2% elongation KN/m≥ | 6 | 10 | 12 | 26 | 30 | 39 | 45 | 56 | 59 | 65 | 78 | 84.5 | 90 |

Tensile strength at 5% elongation KN/m≥ | 12 | 22 | 28 | 48 | 60 | 77 | 90 | 112 | 120 | 132 | 157 | 170 | 182 |

Creep Ultimate Strength KN/m≥ | 11 | 15 | 21 | 30.2 | 41 | 49 | 57 | 64 | 71.5 | 79 | 86 | 91.5 | 100 |

Width (m) | 1~3 | ||||||||||||