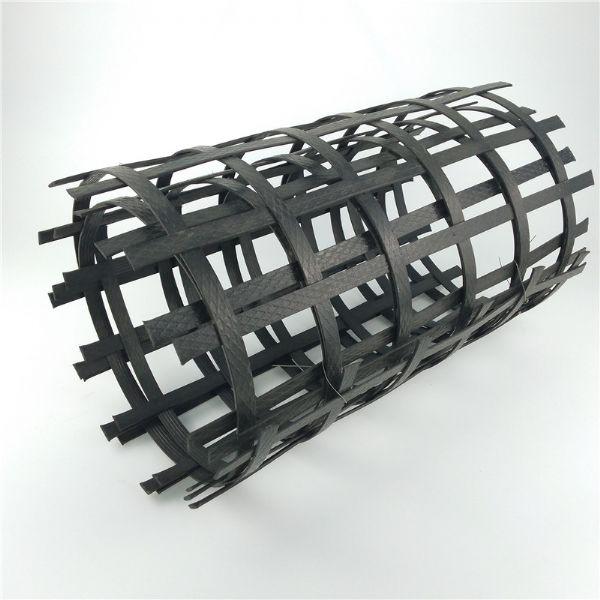

Steel-plastic Composite Geogrid

Steel-plastic Composite Geogrid-The steel-plastic composite Geogrid is made of high-strength metal wire (or different fibers), which is mainly treated, and polyethylene (PE), and different components are introduced to make it a composite high-strength tensile strip thru extrusion, and the floor is rough. Embossed, it is a high-strength bolstered geotextile.

From this single belt, weaving or clamping association at a positive distance vertically and horizontally, and welding its junctions with different strengthening bonding fusion welding science to structure a bolstered geogrid.

Steel-plastic Composite Geogrid

This product is made of high-strength metal wire (or different fibers), after distinct treatment, and polyethylene (PE), and other components are delivered to make it a composite high-strength tensile strip thru extrusion, and the floor has hard embossing, then It is a high-strength bolstered geotextile. The single belt is braided or clamped at a positive distance vertically and horizontally, and its joints are welded and shaped with the aid of distinctive strengthening bonding fusion welding technology, which is a strengthened geogrid.

Features:

1. High strength, small creep, appropriate for a number environmental soils, and can entirely meet the use of tall protecting partitions in high-grade highways.

2. It can correctly enhance the interlocking and occlusion of the bolstered bearing surface, radically beautify the bearing ability of the foundation, correctly restrain the lateral displacement of the soil, and beautify the balance of the foundation.

3. Compared with the normal grille, it has the traits of excessive strength, robust bearing capacity, corrosion resistance, anti-aging, massive friction coefficient, uniform holes, handy building and lengthy provider life.

4. It is extra appropriate for deep-sea operations and embankment reinforcement, and essentially solves the technical issues of low strength, terrible corrosion resistance, and quick provider lifestyles brought about with the aid of long-term seawater erosion of gabions made of different materials.

5. It can correctly keep away from development injury brought on by way of being overwhelmed and broken by way of machines and equipment at some point of the development method.

Application:

It can be used in highways, railways, embankments, bridge abutments, development get entry to roads, wharves, revetments, flood embankments, dams, tidal flat treatment, freight yards, slag yards, airports, sports activities fields, environmental safety buildings, gentle soil foundation reinforcement, keeping walls, slope safety and pavement resistance Inferior civil engineering.

Format Application:

When the geogrid is utilized to smooth basis treatment, the graph electricity of the geogrid ought to additionally be decided in accordance to the peak of the subgrade fill whilst finding out the role and quantity of layers of the overlay grid in accordance to the geological conditions.

When the filling peak is higher than 4m, the geogrid can meet the minimal necessities of the industry standard, and the vertical and horizontal final anxiety ought to now not be much less than 20kN/m

When the filling peak is between 3-4m, the vertical and horizontal final tensile pressure of the geogrid shall no longer be much less than 40kN/m.

When the filling top is much less than 3m, the longitudinal and transverse closing tensile pressure of the geogrid is now not much less than 50 kN/m, and the elongation is much less than 4%. It is encouraged to use the GSZ60-60 geogrid when the geogrid is used for the subgrade filling and excavation junction. A bidirectional geogrid no longer much less than 40kN/m must be used, ideally a GSZ60-60 geogrid.

When it is used to widen the historic avenue at the junction of new and ancient roads, study from the technique of the use of grids in the enlargement of Shenyang-Dalian Expressway: for roadbeds with a top larger than three meters, add steel-plastic composite grids at a distance of 20 cm from the pinnacle of the roadbed. For steel-plastic composite grids, the last tensile pressure in the longitudinal course (perpendicular to the route) is higher than or equal to 60kN/m, and the remaining tensile pressure in the transverse route (parallel to the route) is increased than or equal to 20kN/m, and the elongation is ≤4%.

Equipment of Steel-plastic Composite Geogrid

Packing of Steel-plastic Composite Geogrid

Construction of Steel-plastic Composite Geogrid

Related Products

Submitted successfully

We will contact you as soon as possible

Submitted successfully

We will contact you as soon as possible