Filament nonwoven roadbed geotextile

Filament nonwoven roadbed geotextileMaterial: PET

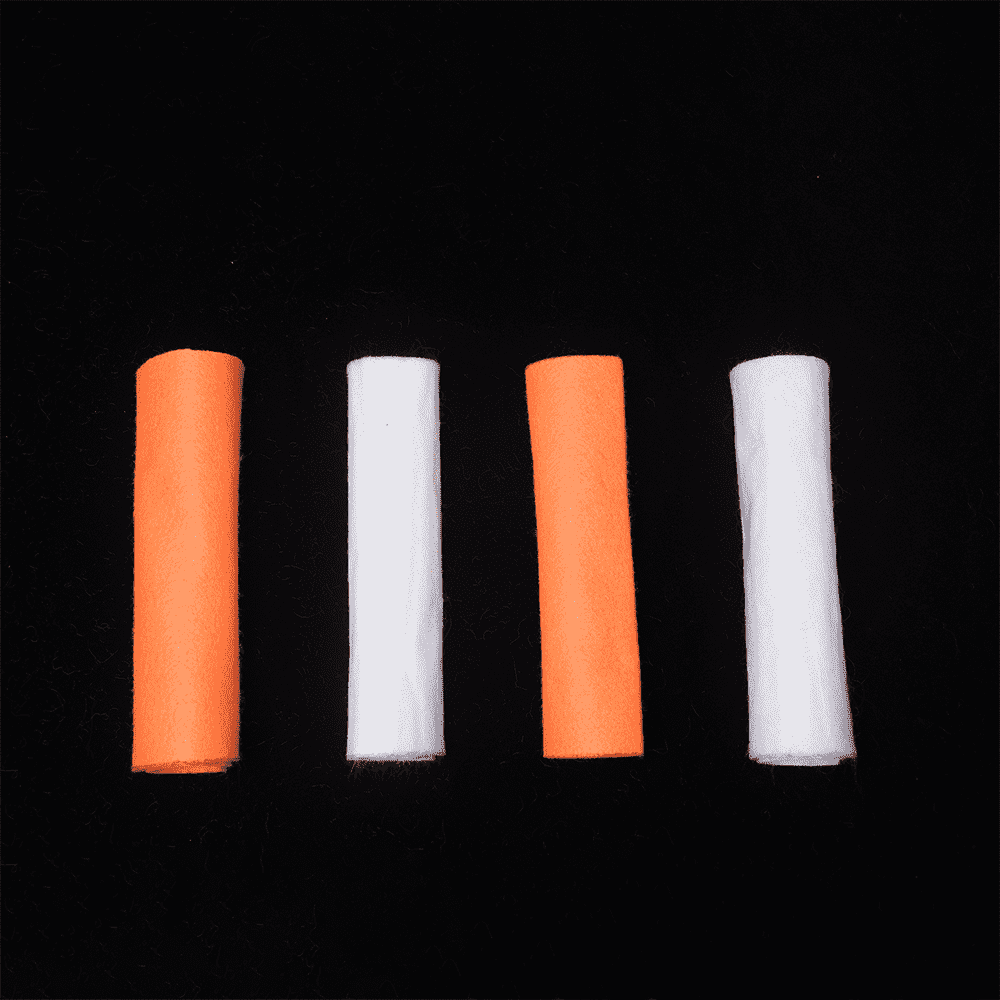

Color: white, black, green, orange, statistics coloration customization

Specifications: 100g-800g

Length: 50-100m

Certificate: CE/ISO9001

Reinforced and constant non-woven geotextileIf there are any special requirements, please inform our customer service personnel (color, length, width)

Filament nonwoven roadbed geotextile

Product introduction;

Our long silk non-woven geotextile is a remarkable product designed for a variety of engineering applications. This versatile fabric is made from long silk fibers, which provide excellent strength and durability. It is widely used in civil engineering, environmental protection, and infrastructure construction.

Product characteristics;

High Strength: Our long silk non-woven geotextile has exceptional tensile strength, allowing it to withstand heavy loads and provide great support to the surrounding soil and materials.

Filtration Properties: This geotextile has excellent filtration capabilities, preventing soil erosion and retaining fine particles within its structure. It helps maintain soil stability and minimizes the risk of ground contamination.

Water Permeability: The fabric's unique structure enables efficient water flow, promoting drainage and preventing water accumulation. This feature is especially useful in areas prone to high water levels, ensuring the longevity and stability of the construction.

Chemical Resistance: Our long silk non-woven geotextile exhibits high resistance to various chemicals, including acids, alkalis, and organic solvents, making it suitable for use in harsh environments.

UV Resistance: The geotextile is manufactured with UV stabilization additives, providing excellent protection against the harmful effects of prolonged sun exposure.

Easy Installation: The lightweight nature of the fabric makes it easy to handle and install, reducing labor costs and construction time.

Application:

Road Stabilization: Our long silk non-woven geotextile is commonly used as a separation and reinforcement layer in road construction. It helps prevent soil mixing and enhances bearing capacity, extending the road's lifespan.

Erosion Control: It provides effective erosion control in slopes, embankments, and riverbanks. By creating a stable layer, it prevents soil erosion and helps maintain landscape integrity.

Drainage Systems: The geotextile is widely used in drainage systems, such as retaining walls, tunnels, and landfills. It facilitates efficient water flow while preventing clogging, ensuring proper functionality and long-term stability of these structures.

Environmental Protection: Our long silk non-woven geotextile is often utilized in environmental protection projects, such as wetland restoration and land reclamation. It acts as a barrier, preventing soil and ecological damage caused by aggressive erosion or containment leakage.

Specifications

Filament Needled Non-woven Geotextile Technical Specifications ( GB/T17639-2008) | |||||||||

Nominal Breaking Strength KN/m | 4.5 | 7.5 | 10 | 15 | 20 | 25 | 30 | 40 | 50 |

MD/CD Break Strength≥KN/m | 4.5 | 7.5 | 10 | 15 | 20 | 25 | 30 | 40 | 50 |

Elongation At Break% | 40%-80% | ||||||||

CBR KN | 0.8 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 |

MD/CD Tearing Strength | 0.14 | 0.21 | 0.28 | 0.42 | 0.56 | 0.70 | 0.82 | 1.10 | 1.25 |

Thickness(mm) | 0.8 | 1.2 | 1.6 | 2.2 | 2.8 | 3.4 | 4.2 | 5.5 | 6.8 |

Unit Weight Tolerance% | -5 | ||||||||

Eos90(95),mm | 0.05-0.2 | ||||||||

Vertical Peability Coefficient cm/s | K*(10-1~10-3)K=1.0-9.9 | ||||||||

Width Deviation | -0.5 | ||||||||

Packing of Top Quality Nonwoven Polypropylene Geotextile Price

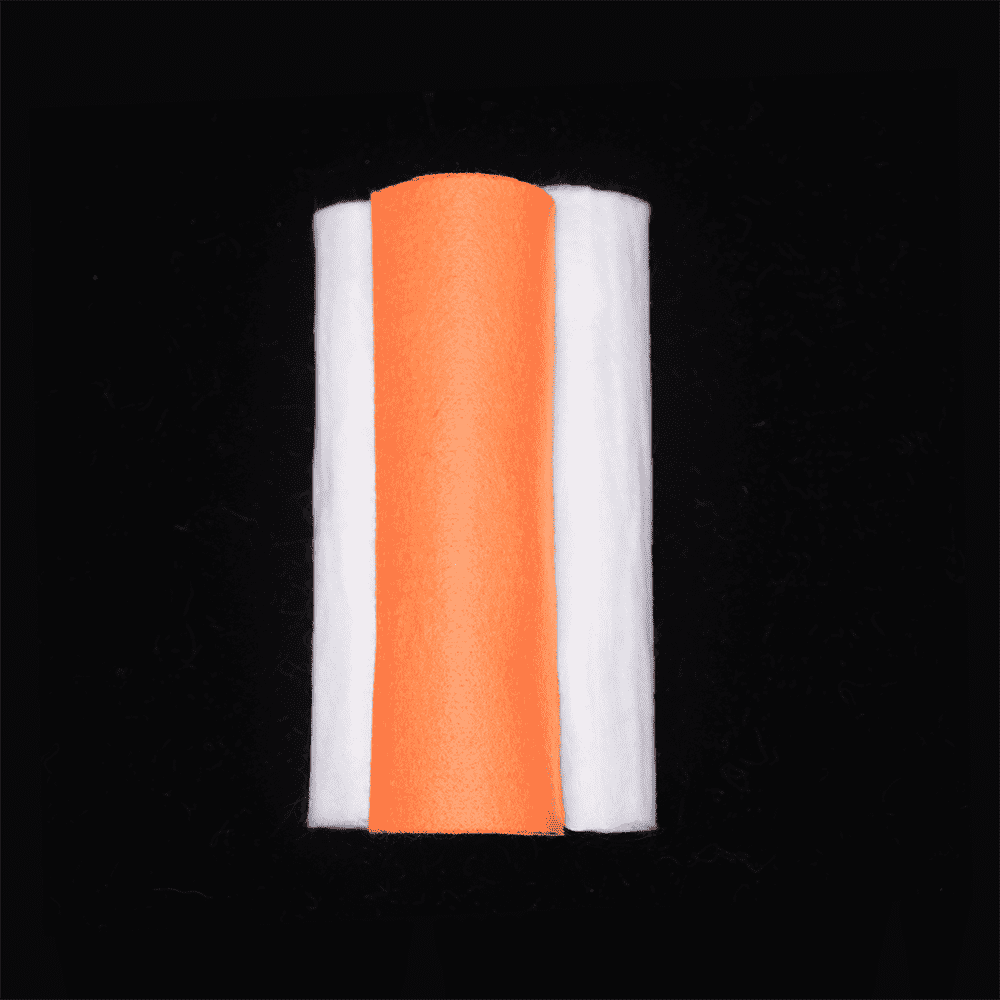

You can freely choose PE film or PP woven bag for outer packaging, and there are paper tubes of different sizes inside the product for you to choose freely.

100

Staple Fiber Needled Non-woven Geotextile Technical Specifications ( GB/T17638-1998) | |||||||||||||

No. | Item | Specifications | Note | ||||||||||

100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 800 | |||

1 | Unit area mass deviation | -8 | -8 | -8 | -8 | -7 | -7 | -7 | -7 | -6 | 6 | -6 |

|

2 | Thickness mm≥ | 0.9 | 1.3 | 1.7 | 2.1 | 2.4 | 2.7 | 3.0 | 3.3 | 3.6 | 4.1 | 5.0 | |

3 | Width deviation | -0.5 | |||||||||||

4 | Breaking strength | 2.5 | 4.5 | 6.5 | 8.0 | 9.5 | 11 | 12.5 | 14.0 | 16.0 | 19.0 | 25.0 | Vertical and horizontal |

5 | Elongation at break % | 20-100 | |||||||||||

6 | CBR bursting strength | 0.3 | 0.6 | 0.8 | 1.2 | 1.4 | 1.8 | 2.1 | 2.4 | 2.7 | 3.2 | 4.0 |

|

7 | Equivalent aperture | 0.07-0.2 |

| ||||||||||

8 | Vertical permeability coefficient | K*(10-1~10-3) | K=1.0-9.9 | ||||||||||

9 | Tear strength | 0.08 | 0.12 | 0.16 | 0.20 | 0.24 | 0.28 | 0.33 | 0.38 | 0.42 | 0.46 | 0.6 | Vertical and horizontal |