PET filament non-woven geotextile for road and railway laying

Filament nonwoven roadbed geotextileMaterial: PET

Color: white, black, green, orange, statistics coloration customization

Specifications: 100g-800g

Length: 50-200m

Certificate: CE/ISO9001

Reinforced and constant non-woven geotextileIf there are any special requirements, please inform our customer service personnel (color, length, width)

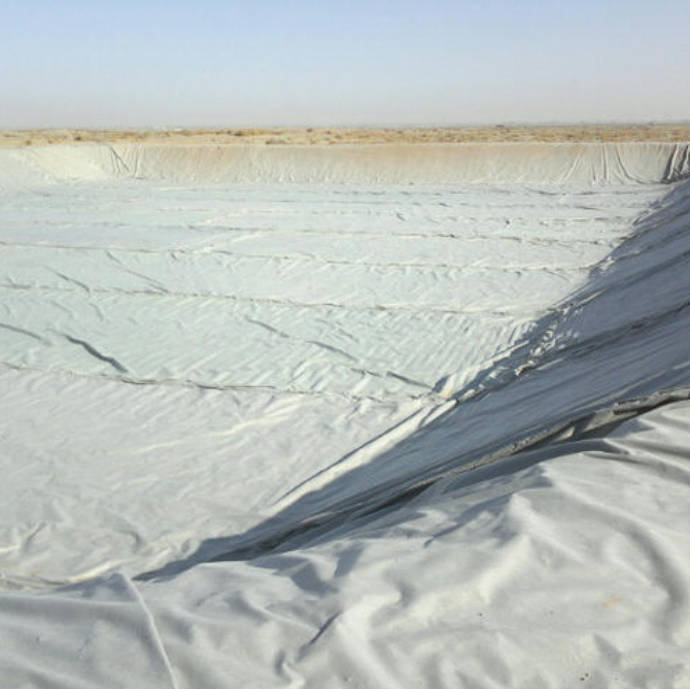

PET filament non-woven geotextile for road and railway laying

Product introduction;

PET long fiber geotextile is a high-quality geosynthetic material that is widely used in the field of civil engineering and construction. It is made from high-strength polyester (PET) fibers that are mechanically bonded together to create a durable and reliable fabric.

Product characteristics;

1.Strong tensile strength: PET long fiber geotextile has excellent tensile strength, providing effective reinforcement and stabilization to soil and structures. It can withstand high loads and stresses, making it suitable for long-term applications.

2.Excellent hydraulic properties: The fabric has excellent permeability, allowing water to pass through easily while retaining the soil particles. This promotes effective drainage and prevents water buildup or erosion in the soil.

3.Chemical resistance: PET long fiber geotextile exhibits high resistance to various chemicals, including acids, alkalis, and organic solvents. It can withstand exposure to aggressive substances, making it suitable for a wide range of environments.

4.UV resistance: The fabric is treated with UV stabilizers, ensuring its resistance to degradation from prolonged exposure to sunlight. This provides long-term durability and performance in outdoor applications.

Application:

1.Road and railway construction: PET long fiber geotextile is used as a separation and filtration layer between subgrade and base course. It prevents mixing of soil layers, provides structural support, and enhances the lifespan of roads and railways.

2.Erosion control: The fabric is highly effective in stabilizing embankments, slopes, and coastal areas prone to erosion. It prevents soil movement, retains soil particles, and allows water to flow through, minimizing erosion.

3.Retaining walls and steep slopes: PET long fiber geotextile acts as a reinforcement layer in retaining wall construction, distributing soil and water pressures. It stabilizes the structure, enhances its strength, and reduces the risk of failure.

4.Landfill and waste management: The fabric is used in landfill liners and caps to provide containment and prevent the migration of pollutants. It offers excellent chemical resistance and reduces the risk of contamination.

5.Filtration and drainage: PET long fiber geotextile is used in various drainage systems, including subsurface drains and French drains. It acts as a filter, allowing water flow while retaining soil particles and preventing clogging.

Specifications

Filament Needled non-woven geotextile Technical Specifications ( GB/T17639-2008) | |||||||||

| Type | TW100 | TW150 | TW200 | TW250 | TW300 | TW350 | TW400 | TW450 | TW500 |

Nominal Breaking Strength KN/m | 4.5 | 7.5 | 10 | 15 | 20 | 25 | 30 | 40 | 50 |

MD/CD Break Strength≥KN/m | 4.5 | 7.5 | 10 | 15 | 20 | 25 | 30 | 40 | 50 |

Elongation At Break% | 40%-80% | ||||||||

CBR KN | 0.8 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 |

MD/CD Tearing Strength | 0.14 | 0.21 | 0.28 | 0.42 | 0.56 | 0.70 | 0.82 | 1.10 | 1.25 |

Thickness(mm) | 0.8 | 1.2 | 1.6 | 2.2 | 2.8 | 3.4 | 4.2 | 5.5 | 6.8 |

Unit Weight Tolerance% | -5 | ||||||||

Eos90(95),mm | 0.05-0.2 | ||||||||

Vertical Peability Coefficient cm/s | K*(10-1~10-3)K=1.0-9.9 | ||||||||

Width Deviation | -0.5 | ||||||||

Packing of Top Quality Nonwoven Polypropylene Geotextile Price

You can freely choose PE film or PP woven bag for outer packaging, and there are paper tubes of different sizes inside the product for you to choose freely.

100

Staple Fiber Needled Non-woven Geotextile Technical Specifications ( GB/T17638-1998) | |||||||||||||

No. | Item | Specifications | Note | ||||||||||

100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 800 | |||

1 | Unit area mass deviation | -8 | -8 | -8 | -8 | -7 | -7 | -7 | -7 | -6 | 6 | -6 |

|

2 | Thickness mm≥ | 0.9 | 1.3 | 1.7 | 2.1 | 2.4 | 2.7 | 3.0 | 3.3 | 3.6 | 4.1 | 5.0 | |

3 | Width deviation | -0.5 | |||||||||||

4 | Breaking strength | 2.5 | 4.5 | 6.5 | 8.0 | 9.5 | 11 | 12.5 | 14.0 | 16.0 | 19.0 | 25.0 | Vertical and horizontal |

5 | Elongation at break % | 20-100 | |||||||||||

6 | CBR bursting strength | 0.3 | 0.6 | 0.8 | 1.2 | 1.4 | 1.8 | 2.1 | 2.4 | 2.7 | 3.2 | 4.0 |

|

7 | Equivalent aperture | 0.07-0.2 |

| ||||||||||

8 | Vertical permeability coefficient | K*(10-1~10-3) | K=1.0-9.9 | ||||||||||

9 | Tear strength | 0.08 | 0.12 | 0.16 | 0.20 | 0.24 | 0.28 | 0.33 | 0.38 | 0.42 | 0.46 | 0.6 | Vertical and horizontal |