Polyester filament needle punched non-woven geotextile

Spunbonded nonwoven

Material: PET/PP

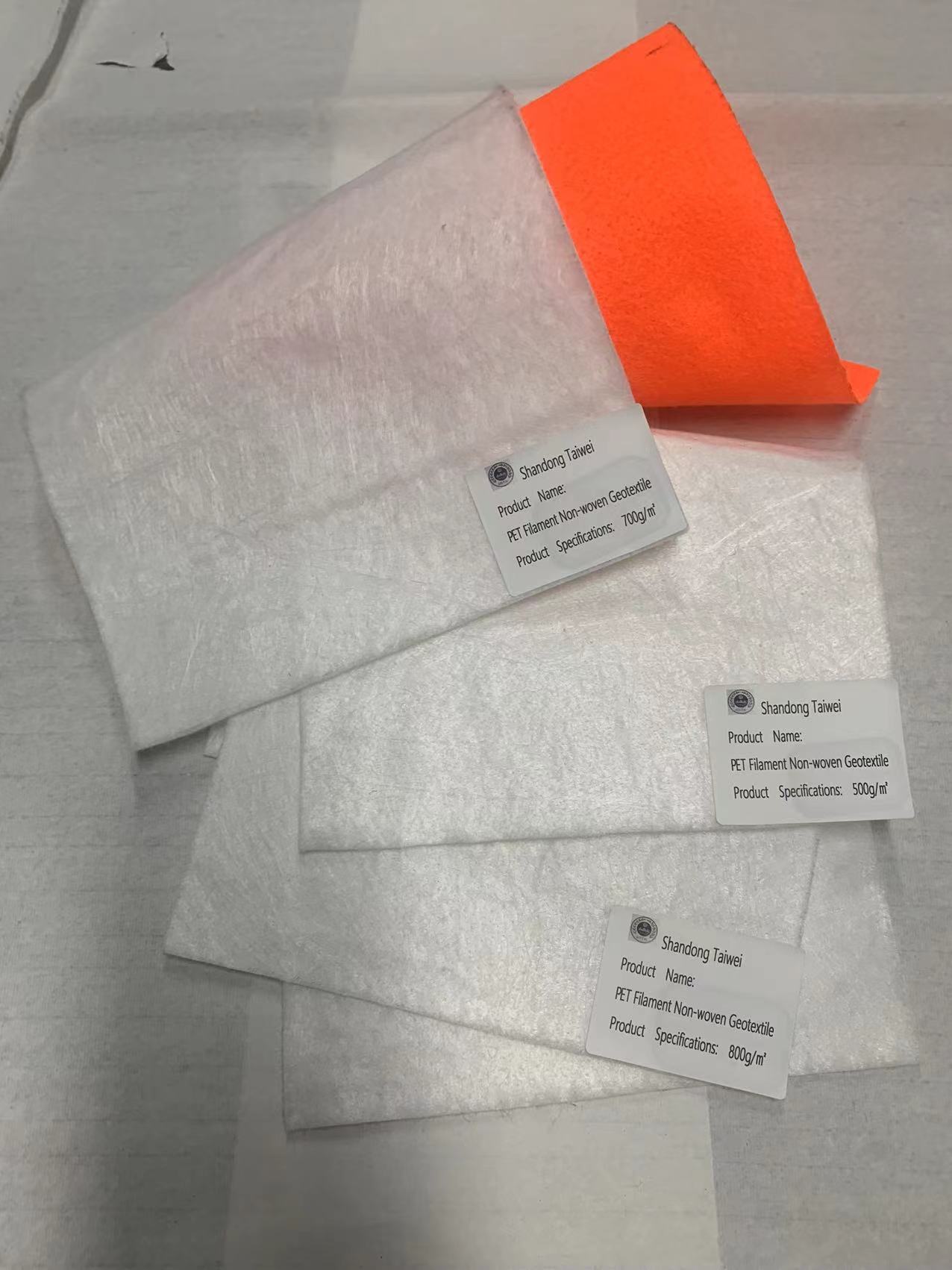

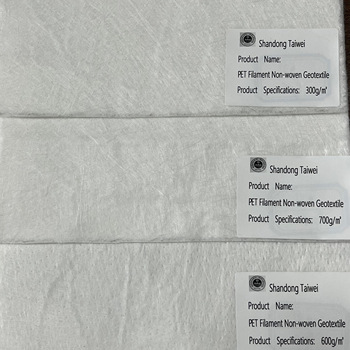

Colors: white, black, green, orange, personalized for statistical coloring

Specification: 100g-800g

Length: 50-100m

Certificate: CE/ISO9001

Support personalized hues and width lengths. Please inform purchaser carrier if there are any different necessities

Leading Geosynthetics Filament geotextile

Product introduction;

Filament geotextile is a polyester filament needle-punched non-woven geotextile, which does not contain chemical additives or undergo heat treatment, and is an environmentally friendly construction material. It is made by the method of netting and consolidation of polyester filaments, and its fibers are arranged into a three-dimensional structure. In addition to good mechanical properties, it also has good longitudinal and transverse drainage properties and good elongation properties and high chemical stability properties such as biological resistance, acid and alkali resistance and aging resistance. At the same time, it also has a wide range of pore size, zigzag pore distribution, excellent permeability and filtration properties.

Product characteristics;

1. Can play a permanent isolation role

It can isolate soil layers composed of different components and properties for a long time and prevent mixing;

Has frost resistance and load-bearing requirements required for construction.

2. Has good filtering performance and anti-corrosion performance

Moisture can penetrate in all directions without pressure buildup. At the same time, it prevents soil loss and is beneficial to stability and anti-corrosion properties.

3. Has reliable drainage performance

Due to the fluffy nature of its structure, it can effectively control the drainage of geotechnical engineering surfaces.

4. Has good protective performance

Due to its good penetrability, extensibility and fluffiness, it can effectively protect the waterproof layer from potential mechanical damage.

5. Has reinforcement properties

The bulkiness and high strength improve the overall stability of the project and increase its strength.

Application scope;

Anti-filtration of water conservancy project dams and berms, isolation and seepage control of channels;

Isolation, anti-filtration, drainage of foundation of highway, railroad and airport runway, reinforcement and drainage of soil slope, retaining wall and road surface;

Soft foundation treatment of harbor project, beach embankment, harbor pier and breakwater reinforcement, drainage;

Polyester filament geotextile has been commonly used in the field of infrastructure construction, gradually being applied to a wider range of fields.

Specifications

Staple Fiber Needled non-woven geotextile Technical Specifications ( GB/T17638-1998) | |||||||||||||

No. | Item | Specifications | Note | ||||||||||

100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 800 | |||

1 | Unit area mass deviation | -8 | -8 | -8 | -8 | -7 | -7 | -7 | -7 | -6 | -6 | -6 |

|

2 | Thickness mm≥ | 0.9 | 1.3 | 1.7 | 2.1 | 2.4 | 2.7 | 3.0 | 3.3 | 3.6 | 4.1 | 5.0 | |

3 | Width deviation | -0.5 | |||||||||||

4 | Breaking strength | 2.5 | 4.5 | 6.5 | 8.0 | 9.5 | 11 | 12.5 | 14.0 | 16.0 | 19.0 | 25.0 | Vertical and horizontal |

5 | Elongation at break % | 20-100 | |||||||||||

6 | CBR bursting strength | 0.3 | 0.6 | 0.8 | 1.2 | 1.4 | 1.8 | 2.1 | 2.4 | 2.7 | 3.2 | 4.0 |

|

7 | Equivalent aperture | 0.07-0.2 |

| ||||||||||

8 | Vertical permeability coefficient | K*(10-1~10-3) | K=1.0-9.9 | ||||||||||

9 | Tear strength | 0.08 | 0.12 | 0.16 | 0.20 | 0.24 | 0.28 | 0.33 | 0.38 | 0.42 | 0.46 | 0.6 | Vertical and horizontal |

Packing of Top Quality Nonwoven Polypropylene Geotextile Price

You can freely choose PE film or PP woven bag for outer packaging, and there are paper tubes of different sizes inside the product for you to choose freely.

Staple Fiber Needled Non-woven Geotextile Technical Specifications ( GB/T17638-1998) | |||||||||||||

No. | Item | Specifications | Note | ||||||||||

100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 800 | |||

1 | Unit area mass deviation | -8 | -8 | -8 | -8 | -7 | -7 | -7 | -7 | -6 | 6 | -6 |

|

2 | Thickness mm≥ | 0.9 | 1.3 | 1.7 | 2.1 | 2.4 | 2.7 | 3.0 | 3.3 | 3.6 | 4.1 | 5.0 | |

3 | Width deviation | -0.5 | |||||||||||

4 | Breaking strength | 2.5 | 4.5 | 6.5 | 8.0 | 9.5 | 11 | 12.5 | 14.0 | 16.0 | 19.0 | 25.0 | Vertical and horizontal |

5 | Elongation at break % | 20-100 | |||||||||||

6 | CBR bursting strength | 0.3 | 0.6 | 0.8 | 1.2 | 1.4 | 1.8 | 2.1 | 2.4 | 2.7 | 3.2 | 4.0 |

|

7 | Equivalent aperture | 0.07-0.2 |

| ||||||||||

8 | Vertical permeability coefficient | K*(10-1~10-3) | K=1.0-9.9 | ||||||||||

9 | Tear strength | 0.08 | 0.12 | 0.16 | 0.20 | 0.24 | 0.28 | 0.33 | 0.38 | 0.42 | 0.46 | 0.6 | Vertical and horizontal |