Special filament non-woven geotextile for railways, highways and bridges

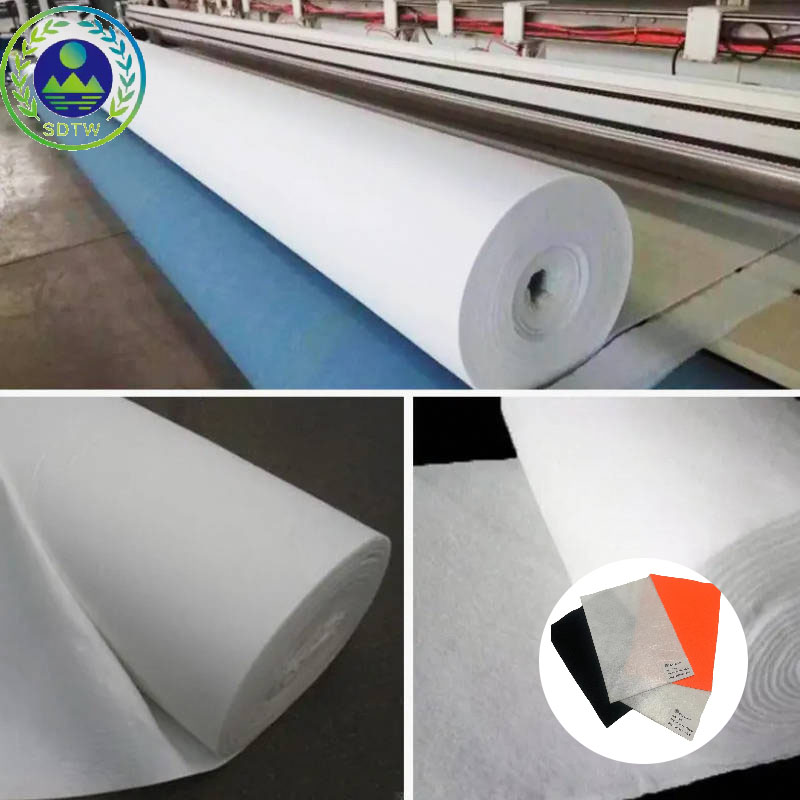

PET Geotextile Manufacturer -PET Geotextile the usage of PET as uncooked material, adopts soften spinning, air-laid and needle-punching consolidation method to produce geotextiles with three-dimensional pores.High mechanical index, suitable creep performance; sturdy corrosion resistance, creating older resistance, extraordinarily properly warmth resistance, wonderful hydraulic performance.

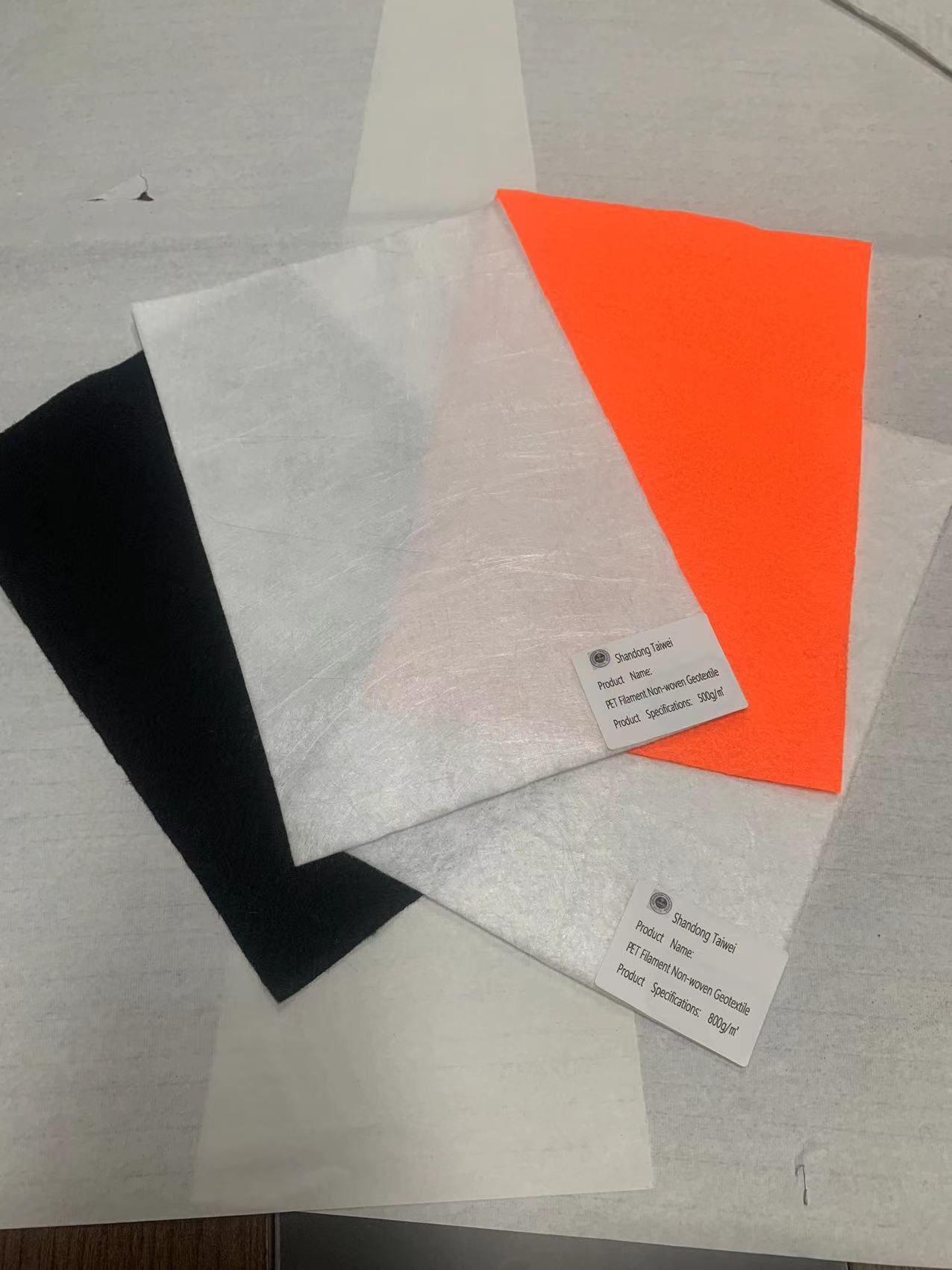

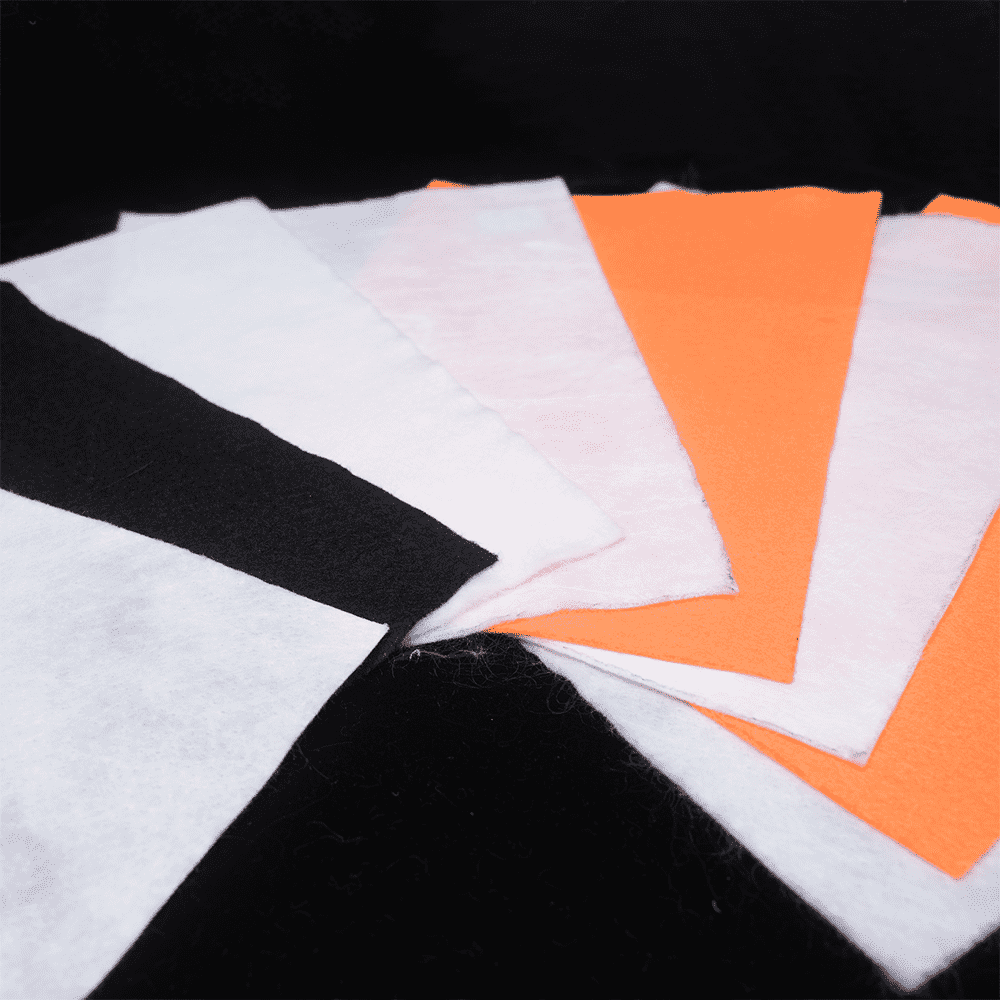

●Material:Polyester

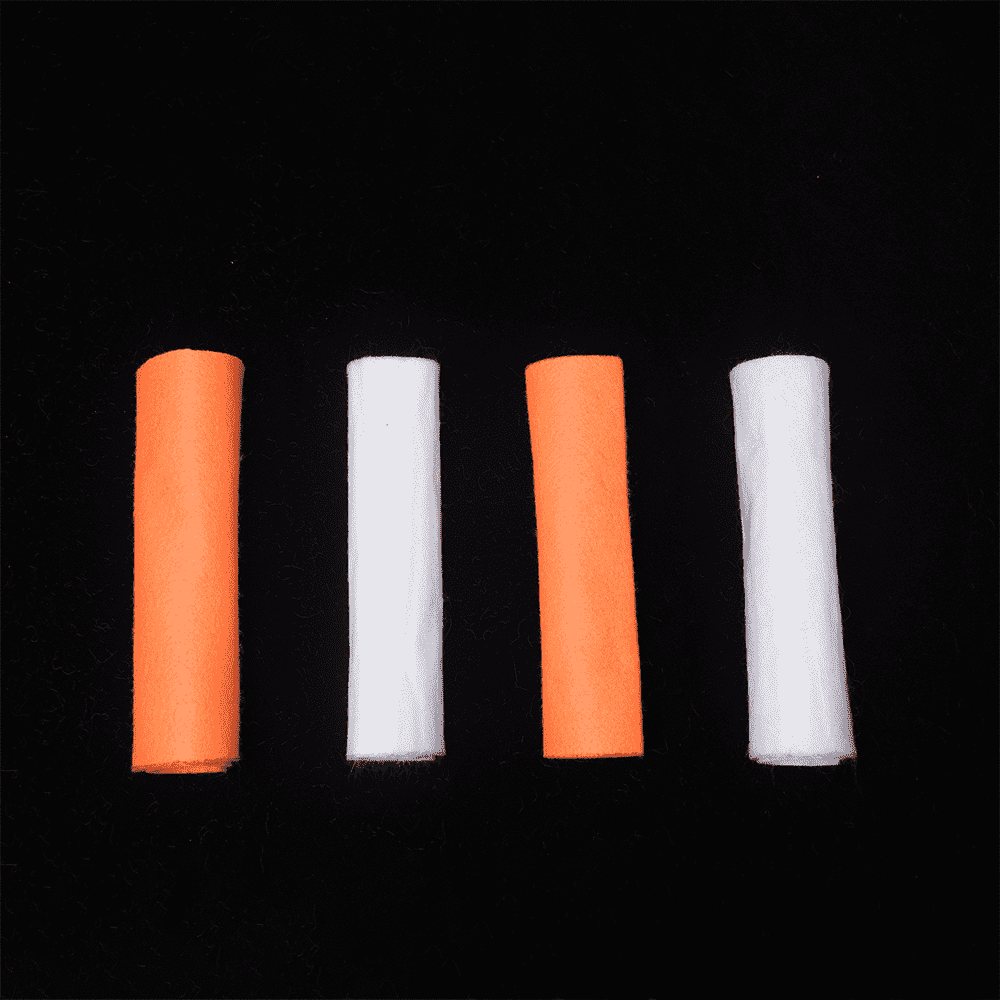

●Color: White,Black,Orange

●Unit weight:100gsm-800gsm

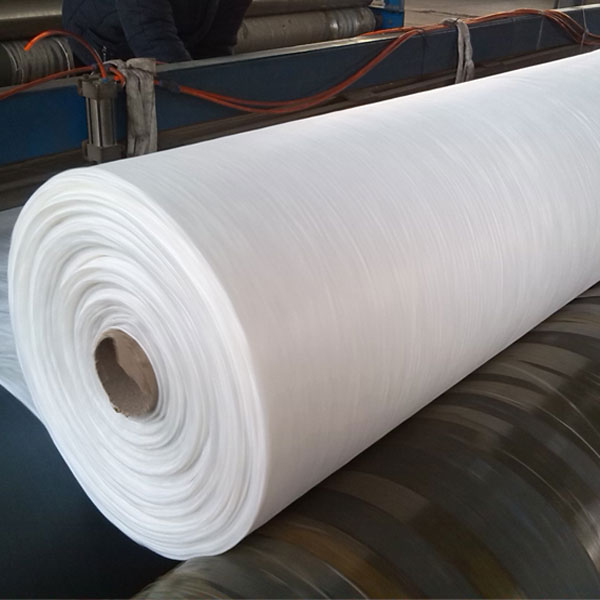

●Length: Customized according to customer needs

●Width: 1-7m

●Certificate: CE /ISO9001

●Type: Needle Punched

Special filament non-woven geotextile for railways, highways and bridges

Product introduction:

Long Fiber Non-woven geotextiles, commonly referred to as geotextiles, are a versatile and durable material used in civil engineering and construction projects. They are made from high-quality synthetic fibers, processed through advanced production techniques to create a strong and reliable product. With their excellent physical and mechanical properties, long fiber Non-woven Geotextiles effectively enhance the performance and lifespan of various construction projects.

Product features:

●High Strength: Our long fiber non-woven geotextiles have superior tensile strength, providing stability and reinforcement to the construction site. They can withstand heavy loads and distribute stress evenly, preventing soil erosion and promoting long-term stability.

●Filtration and Drainage: These geotextiles efficiently separate and filter different soil layers, allowing water to pass through while retaining fine particles. This feature helps in preventing clogging and ensures efficient drainage in various applications, including landfills, road construction, and slope protection.

●Soil Stabilization: By effectively distributing pressure and reducing water flow, long fiber non-woven geotextiles improve the load-bearing capacity of soils. They prevent soil movement and maintain stability, making them ideal for applications such as railway tracks, embankments, and retaining walls.

●Environmental Protection: Our long fiber non-woven geotextiles are environmentally friendly and chemically stable. They are resistant to degradation, UV radiation, and chemical substances commonly found in the soil. This durability ensures long-lasting performance and harm-free interactions with the environment.

Application:

●Road Construction: Long fiber non-woven geotextiles are widely used in road projects to improve the strength of the subgrade, prevent differential settlement, and minimize soil erosion.

●Drainage Systems: These geotextiles are utilized in drainage systems, such as landfills, sports fields, and agricultural facilities, to filter water and prevent the clogging of drainage pipes.

●Erosion Control: Long fiber non-woven geotextiles effectively control erosion by providing stabilization and reinforcement to slopes, embankments, and riverbanks.

●Landscape and Gardens: These geotextiles are used in gardening and landscaping applications to separate different soil layers, provide drainage, and prevent weed growth.

Product implementation standards: national standard (GB/T 17639-2008)

| Filament Spunbonded Needled non-woven geotextile Technical Specifications | ||||||||||

| Item | Index | |||||||||

| Index breaking strength(KN/m) | 4.5 | 7.5 | 10 | 15 | 20 | 25 | 30 | 40 | 50 | |

| 1 | Vertical and horizontal rupture strength / (KN/ m) | 4.5 | 7.5 | 10 | 15 | 20 | 25 | 30 | 40 | 50 |

| 2 | Vertical and horizontal standard strength corresponding to elongation % | 40-80 | ||||||||

| 3 | CBR bursting strength /KN | 0.8 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 |

| 4 | Vertical and horizontal tearing strength /KN | 0.14 | 0.21 | 0.28 | 0.42 | 0.56 | 0.70 | 0.82 | 1.10 | 1.25 |

| 5 | Equivalent aperture O90(95)>/mm | 0.05-0.20 | ||||||||

| 6 | Vertical permeability coefficient | K*(10-1~10-3)and K=1.0~9.9 | ||||||||

| 7 | Thickness / mm≥ | 0.8 | 1.2 | 1.6 | 2.2 | 2.8 | 3.4 | 4.2 | 5.5 | 6.8 |

| 8 | Width deviation | -0.5 | ||||||||

| 9 | Unit area mass deviation | -5 | ||||||||

Packing of PET Geotextile

You can freely choose PE film or PP woven bag for outer packaging, and there are paper tubes of different sizes inside the product for you to choose freely.

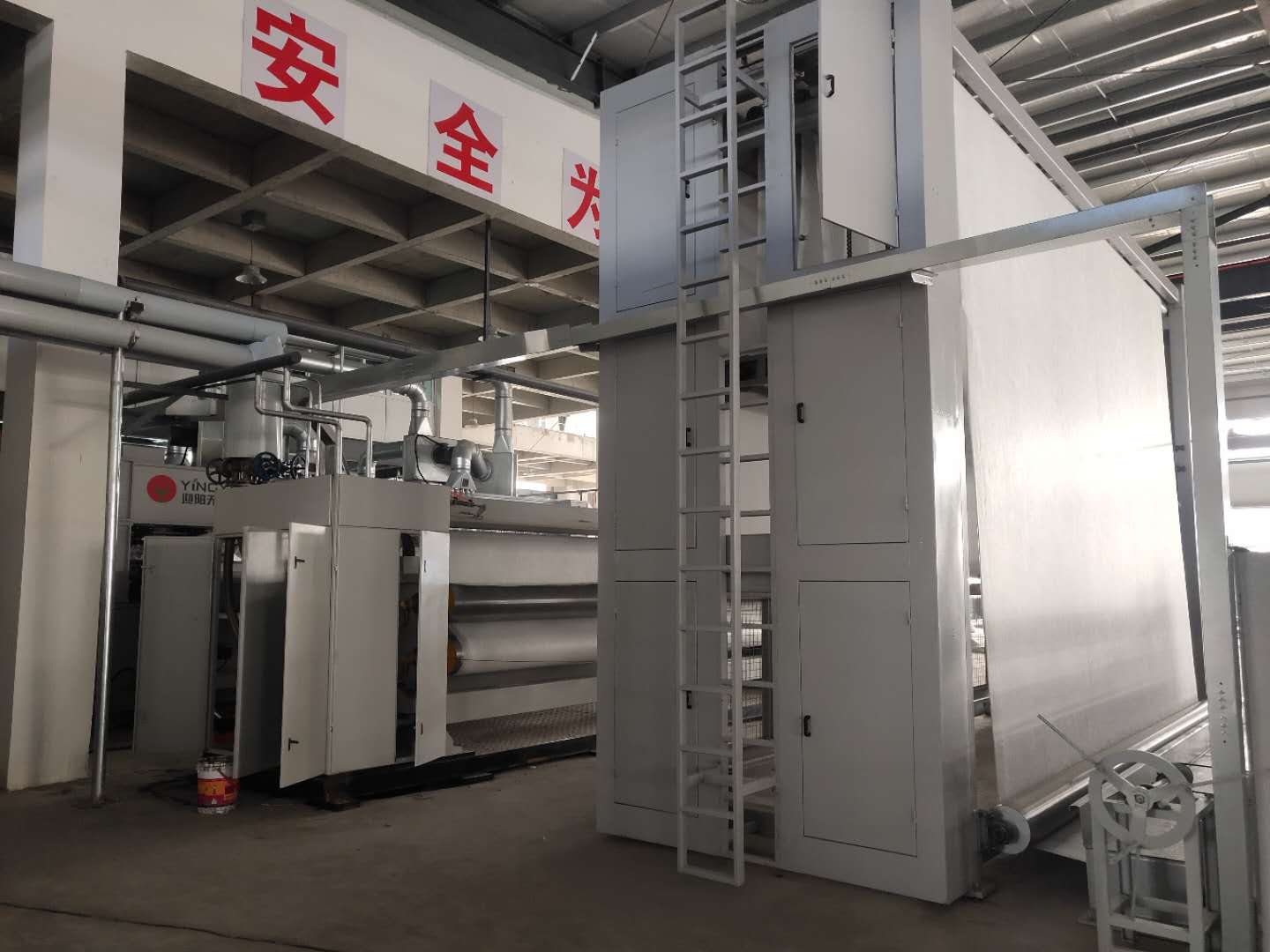

Strength of the company

The employer has impartial geotextile manufacturing equipment, skilled technical personnel, a giant manufacturing group and a expert after-sales team. The annual output of geotextiles is greater than 30 million rectangular meters. Products are extensively used in landfills, synthetic lakes, rivers, canals, subways, basements, highways, railways, tunnels and different projects. It has been identified as a incredible fabric provider by way of the country wide authority and bought overseas.