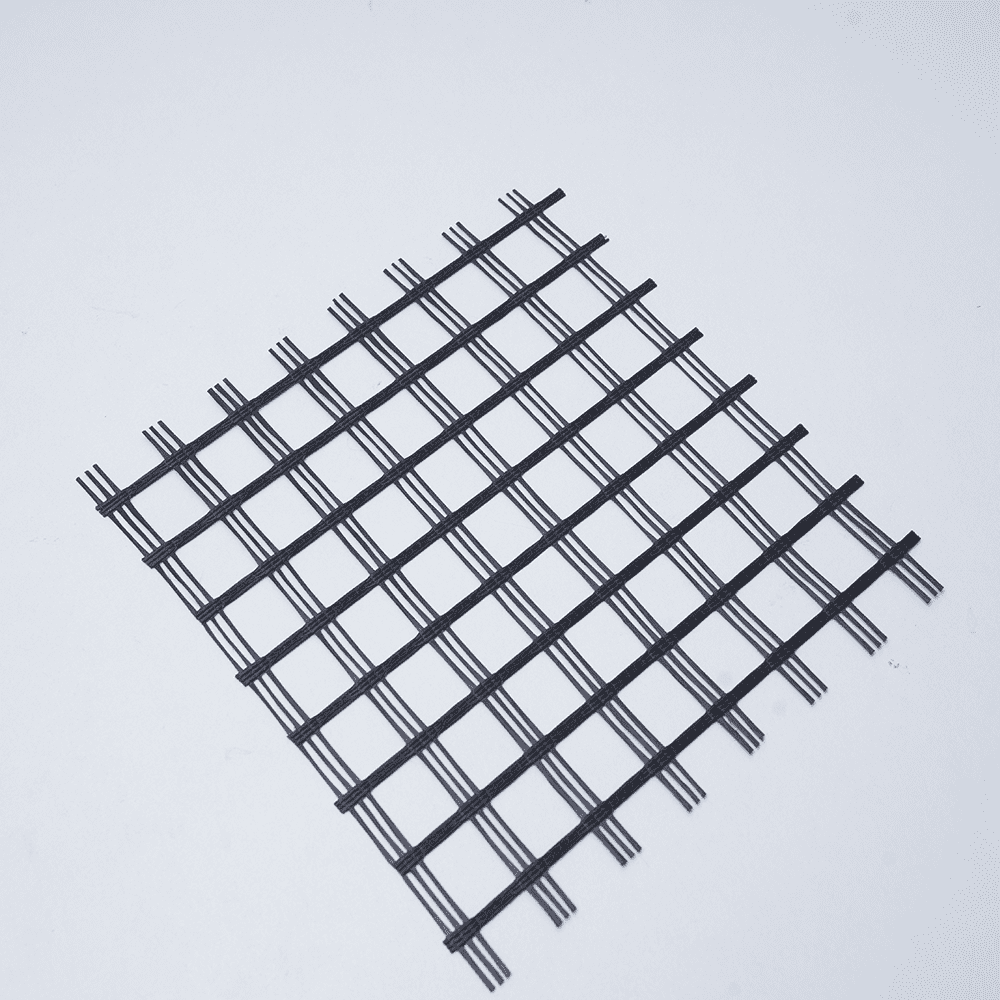

Reinforced subgrade mesh fiberglass geogrid

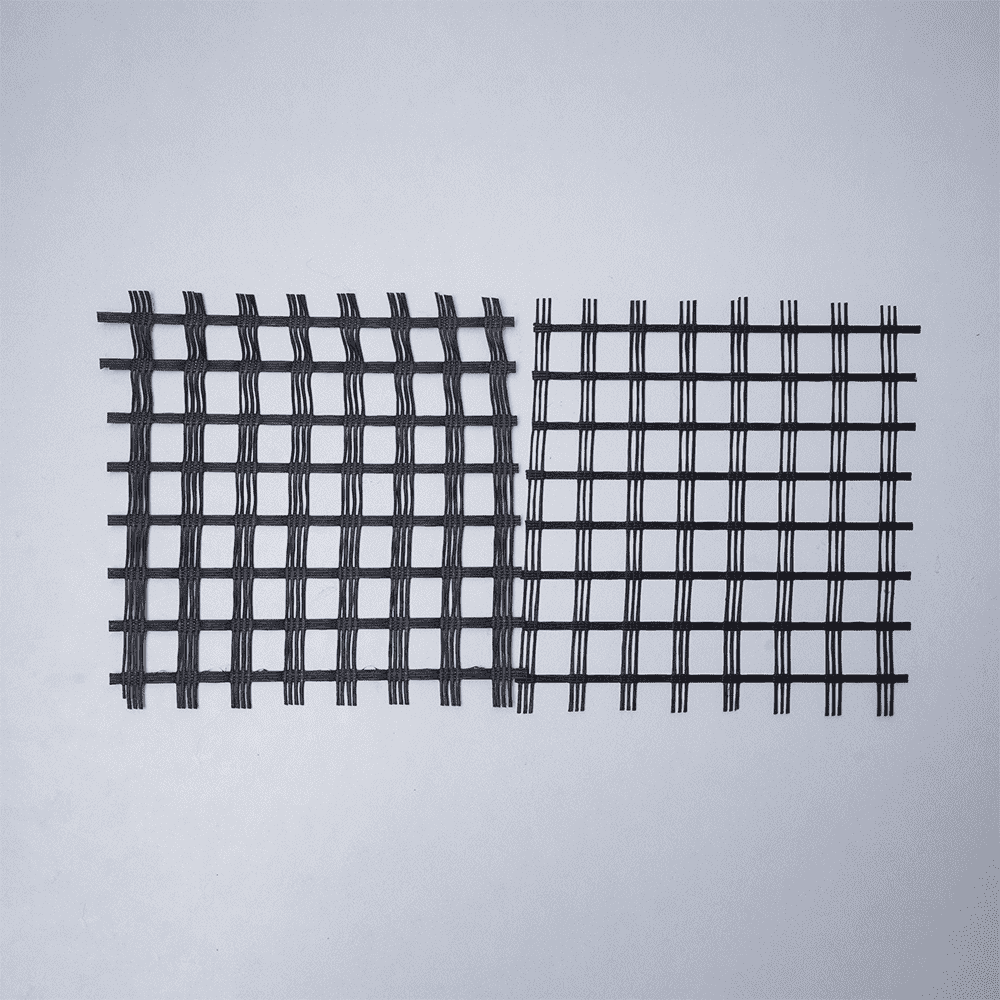

Geogrids are divided into

1.There are four major categories of plastic geogrids, steel plastic geogrids, glass fiber geogrids, and polyester warp knitted polyester geogrids.

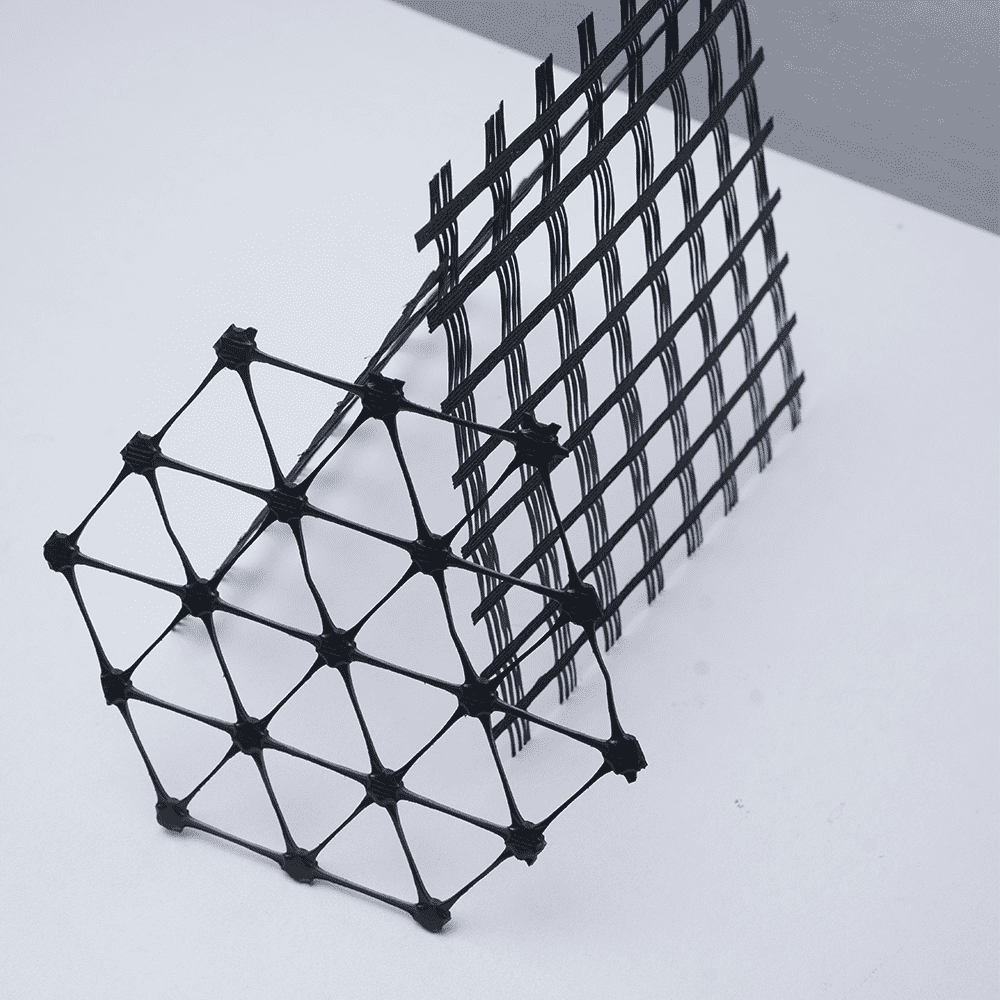

2.Grille is a two-dimensional grid or three-dimensional grid with a certain height formed by thermoplastic or molded high polymer materials such as polypropylene and polyvinyl chloride.

Reinforced subgrade mesh fiberglass geogrid

Product Introduction: Fiberglass Geogrid:

The Glass Fiber Geogrid is a type of geosynthetic material made from high-strength glass fibers that are woven into a grid structure. It is widely used in various civil engineering applications, such as road construction, railway construction, and slope stabilization.

Features:

The Glass Fiber Geogrid offers many advantages over traditional construction materials.

1.Its high tensile strength and low elongation properties provide excellent reinforcement for soil and asphalt aggregates, enhancing the overall stability and load-bearing capacity of the structure. This makes it an ideal solution for areas with poor soil conditions or heavy traffic loads.

2.The Glass Fiber Geogrid is its resistance to chemical degradation. Unlike metallic reinforcements, it is immune to corrosion and can withstand exposure to harsh environments, including high acidity or alkalinity. This not only ensures its long-term durability but also reduces maintenance costs in the long run.

3.The Glass Fiber Geogrid is easy to install and can be tailored to meet specific project requirements. It can be applied through various methods, such as direct placement, stitch bonding, or asphalt overlay. Its flexibility allows for adjustments depending on the project's needs, ensuring efficient and cost-effective implementation.

4.In terms of sustainability, the Glass Fiber Geogrid is an environmentally friendly choice. It is a non-toxic material that can be recycled, reducing waste generation and contributing to a greener construction industry.

Application :

1.It is suitable for reinforcing roadbeds of various highways, railways and airports.

2.It is suitable for foundation reinforcement of permanent loads such as large parking lots and dock yards.

3.Suitable for protection of railway and highway slopes.

4.It is suitable for culvert reinforcement and soil slope reinforcement, which further strengthens the soil slope and prevents water and soil erosion.

Fiberglass Geogrid Technical Specification | |||||||

Item | Specification | ||||||

EGA 30-30 | EGA 40-40 | EGA 50-50 | EGA 80-80 | EGA 100-100 | EGA 125-125 | EGA 150-150 | |

Mesh size | 12.7×12.7~25.4×25.4 | ||||||

Tensile strength | ≥30 | ≥40 | ≥50 | ≥80 | ≥100 | ≥125 | ≥150 |

Tensile strength at 5% elongation KN/m≥ | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 |

Temperature resistance | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 |

Width (m) | 1~3 | ||||||

Packing of Fiberglass Geogrid Technical Specification

One-way Stretch Plastic Geogrid GB/T17689-1999 | |||||||||||||

Item | Specification | ||||||||||||

TGDG25 | TGDG35 | TGDG50 | TGDG80 | TGDG110 | TGDG150 | TGDG170 | TGDG200 | TGDG220 | TGDG240 | TGDG260 | TGDG280 | TGDG300 | |

Tensile strength KN/m≥ | 25 | 35 | 50 | 80 | 110 | 150 | 170 | 200 | 220 | 240 | 260 | 280 | 300 |

Standard elongation %≤ | 10.0 | ||||||||||||

Tensile strength at 2% elongation KN/m≥ | 6 | 10 | 12 | 26 | 30 | 39 | 45 | 56 | 59 | 65 | 78 | 84.5 | 90 |

Tensile strength at 5% elongation KN/m≥ | 12 | 22 | 28 | 48 | 60 | 77 | 90 | 112 | 120 | 132 | 157 | 170 | 182 |

Creep Ultimate Strength KN/m≥ | 11 | 15 | 21 | 30.2 | 41 | 49 | 57 | 64 | 71.5 | 79 | 86 | 91.5 | 100 |

Width (m) | 1~3 | ||||||||||||