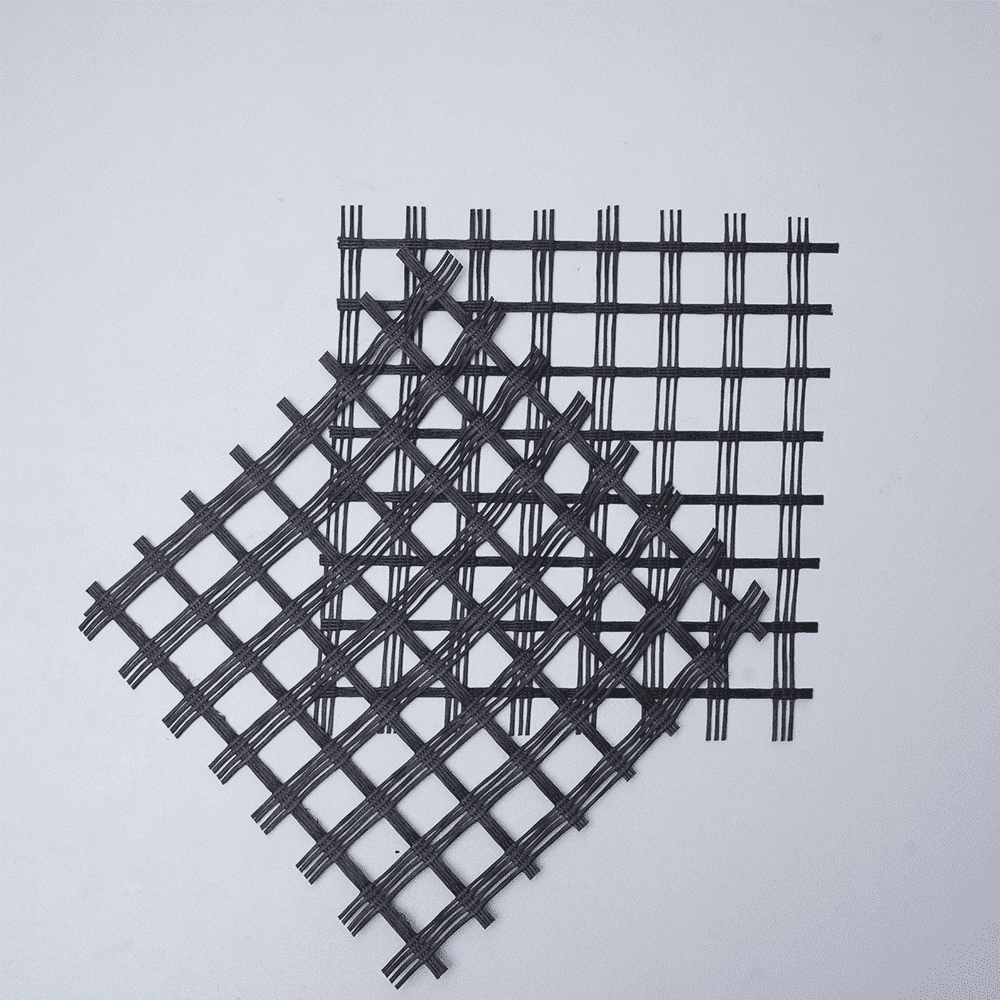

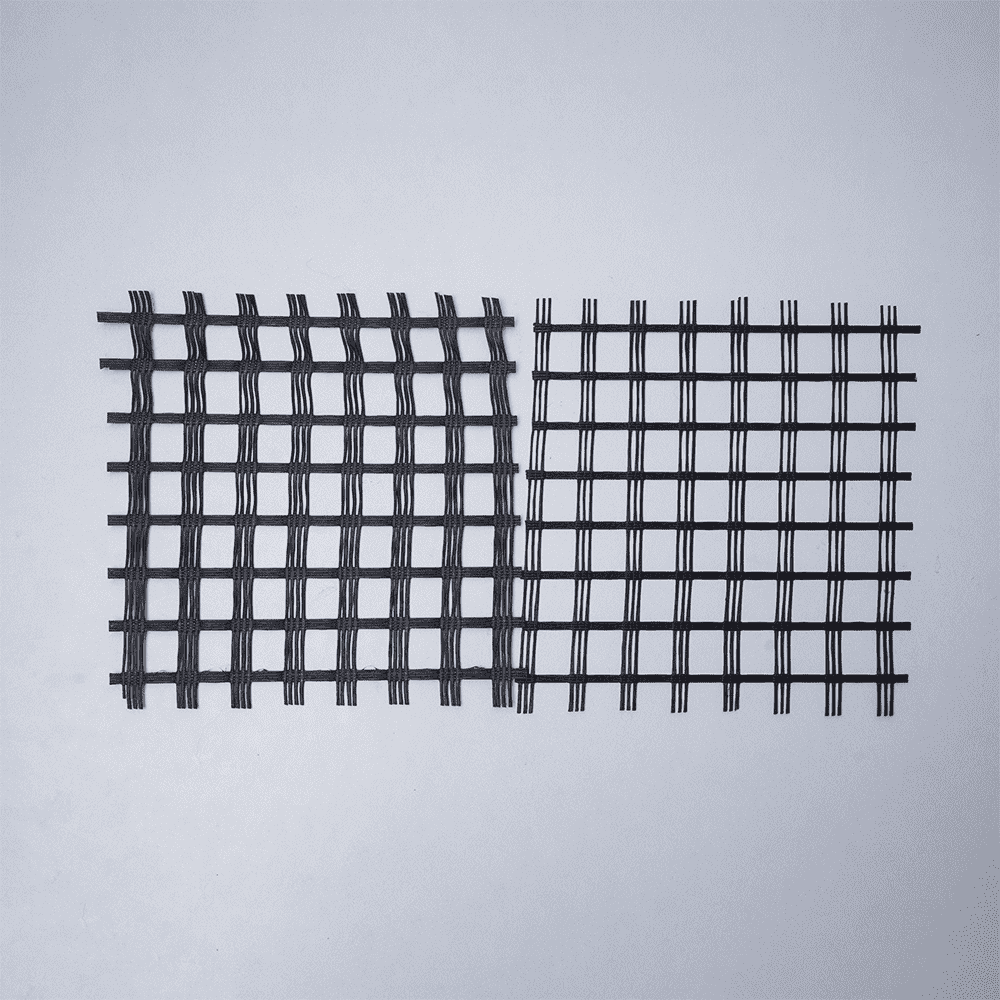

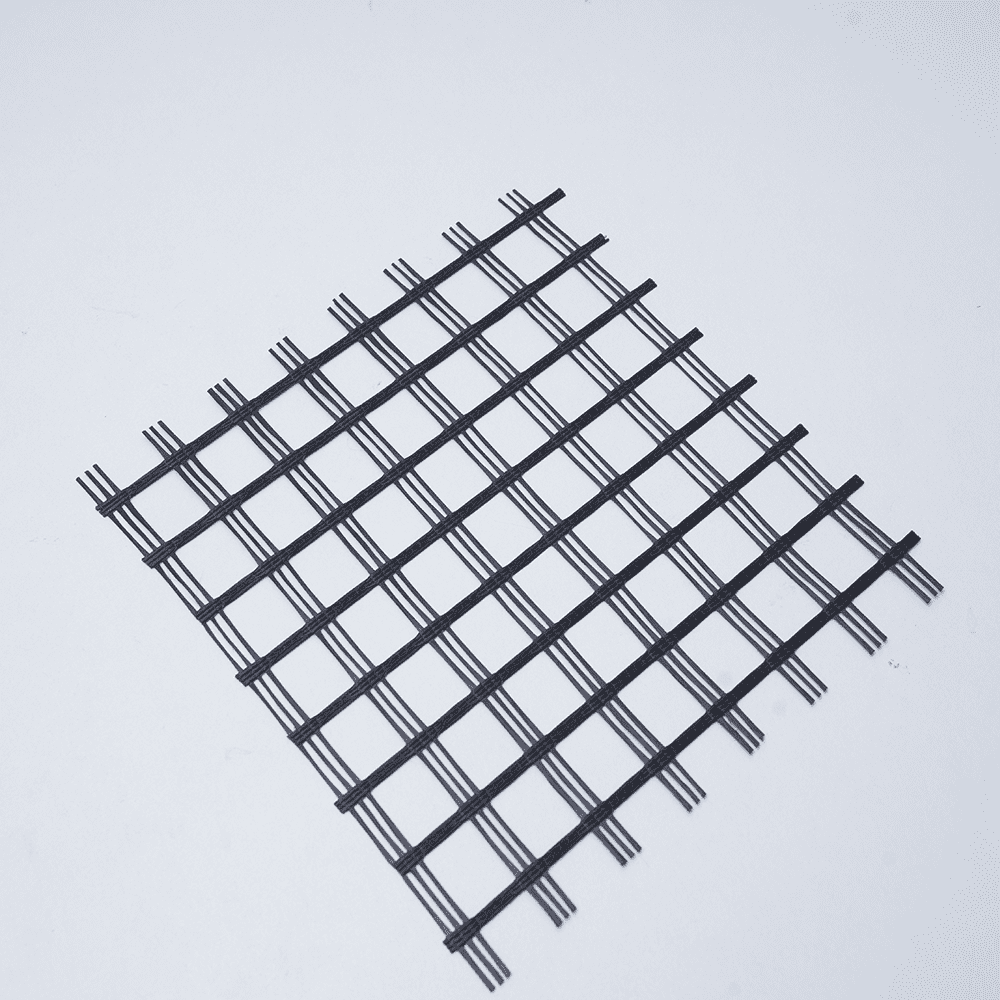

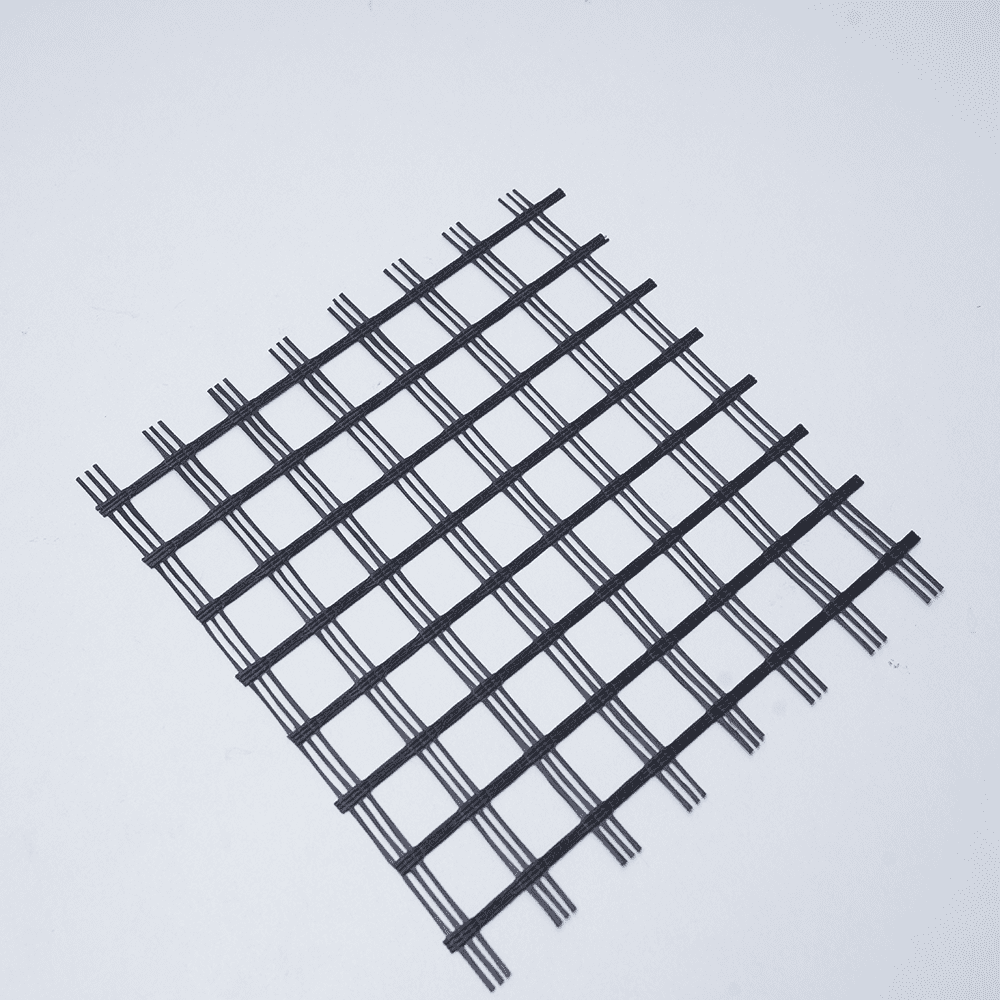

Reinforced asphalt surface fiberglass grating

The mesh structure material is made of GE fiber as the main raw material, advanced weaving process and special coating process. lt can improve the overall performance and is a new type of excellent geotechnical substrate.

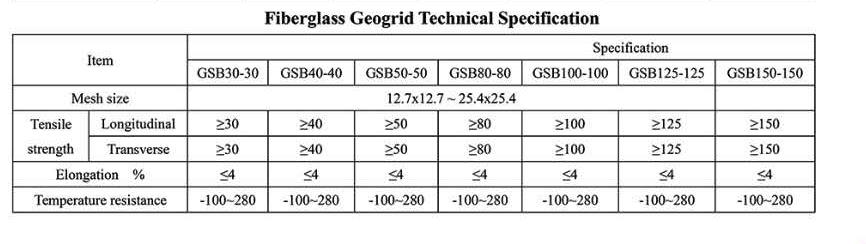

Product Specifications:

EGA30-30,EGA50-50,EGA60-60,EGA80-80,EGA100-100,EGA120-120,EGA150-150,EGA200-200.

Features:

1. The tensile strength of fiberglass geogrid is extremely high, but the elongation rate is very low: the tensile strength can reach 100kN/m,

and the elongation rate at break is about 3%;

2. fiberglass geogrid has no long-term creep: Fiberglass geogrid does not creep, which ensures that the product can be used for a long time;

3. High temperature stability: The melting point of fiberglass geogrid is above 1000℃, and it will not be affected in any way by hot-laying asphalt concrete at 160℃;

4. The fiberglass geogrid has good compatibility with the pavement mixture: after being treated with an organic coating on the surface,

the fiberglass geogrid has good compatibility with the organic matter of the concrete mixture (compatibility with asphalt materials). (Exceptionally good capacitance),

thereby improving the shortcomings of fiberglass geogrids that are not wear-resistant and not resistant to folding;

5. Chemical stability of fiberglass geogrid: After special treatment, fiberglass geogrid can prevent various chemical erosion, biological erosion and climate change;

6. The interlocking and restricting effect of fiberglass geogrid: the asphalt concrete mixture passes through the fiberglass geogrid structure to form a composite interlocking structure.

This restriction can prevent the movement of concrete mixture materials, so that the asphalt concrete mixture can be better compacted, obtain greater load-bearing capacity,

and achieve the purpose of improving load transmission capacity, reducing deformation, and strengthening asphalt concrete pavement.

This is like just like adding steel bars to concrete, it becomes an integral structure and plays a skeleton role in the road cover.

Application:

1. Reinforce the old asphalt concrete pavement to strengthen the asphalt surface layer to prevent and control diseases.

2. Replace the cement concrete pavement with a composite pavement to avoid reflection cracks caused by plate shrinkage.

3. Road expansion and improvement projects to prevent cracks at the junction of new and old areas and uneven settlement.

4. Reinforcement treatment of soft soil foundation is beneficial to the consolidation of water in soft soil, effectively prevents settlement, distributes stress evenly, and enhances the overall strength of the subgrade.

5. Shrinkage cracks occur in the semi-rigid base of newly built roads. Reinforcement is required to prevent pavement cracks caused by reflection of foundation cracks.

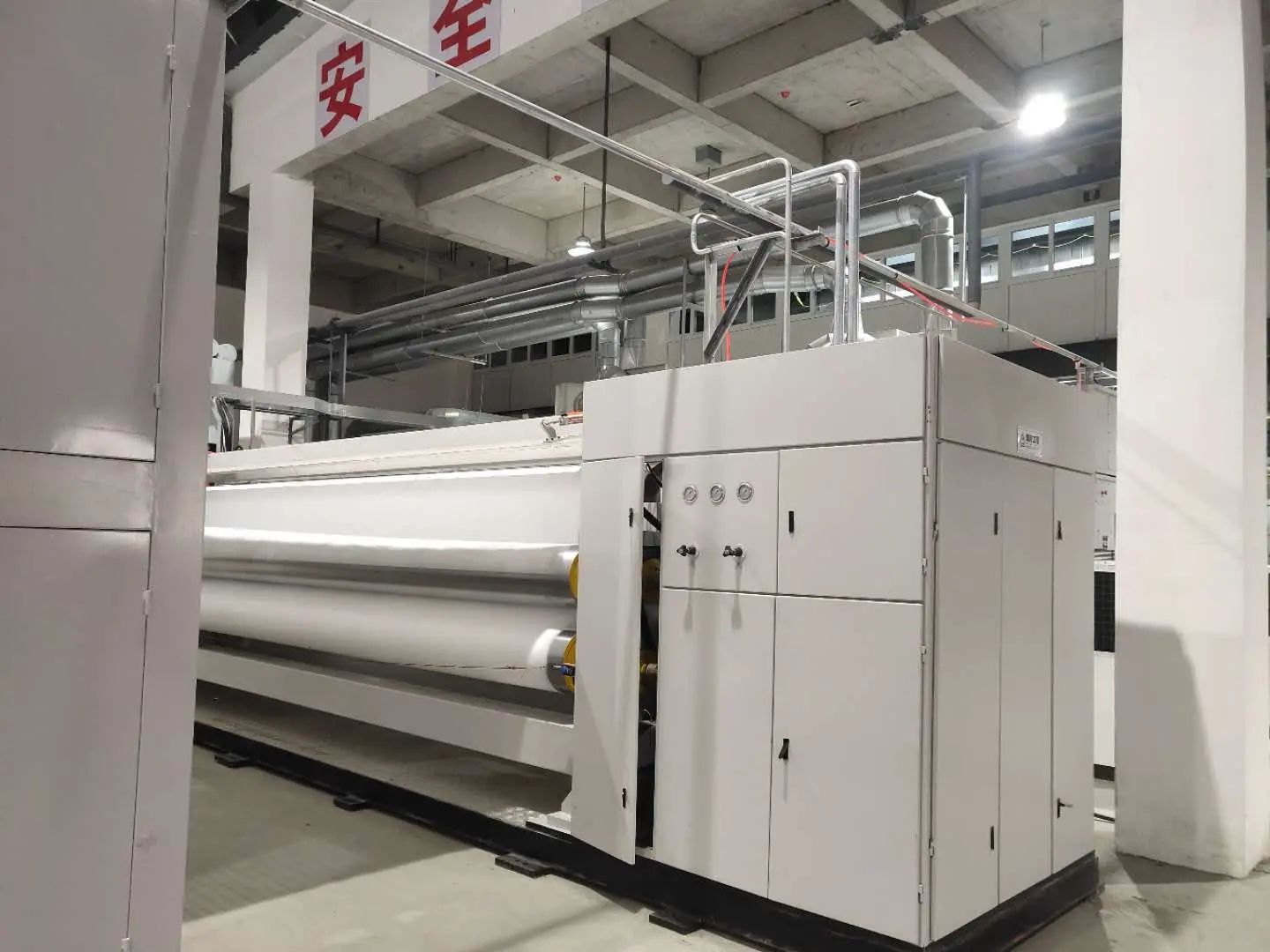

Fiberglass geogrid equipment

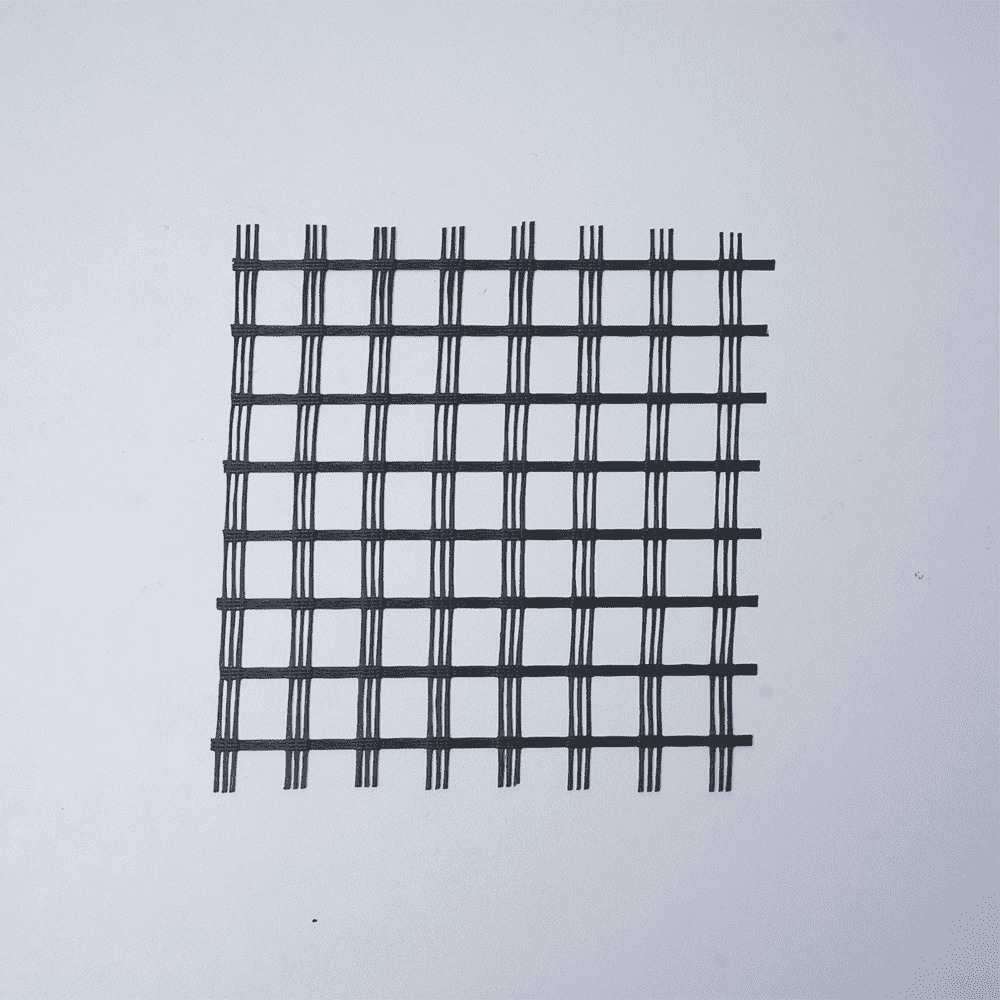

Packing of Fiberglass geogrid

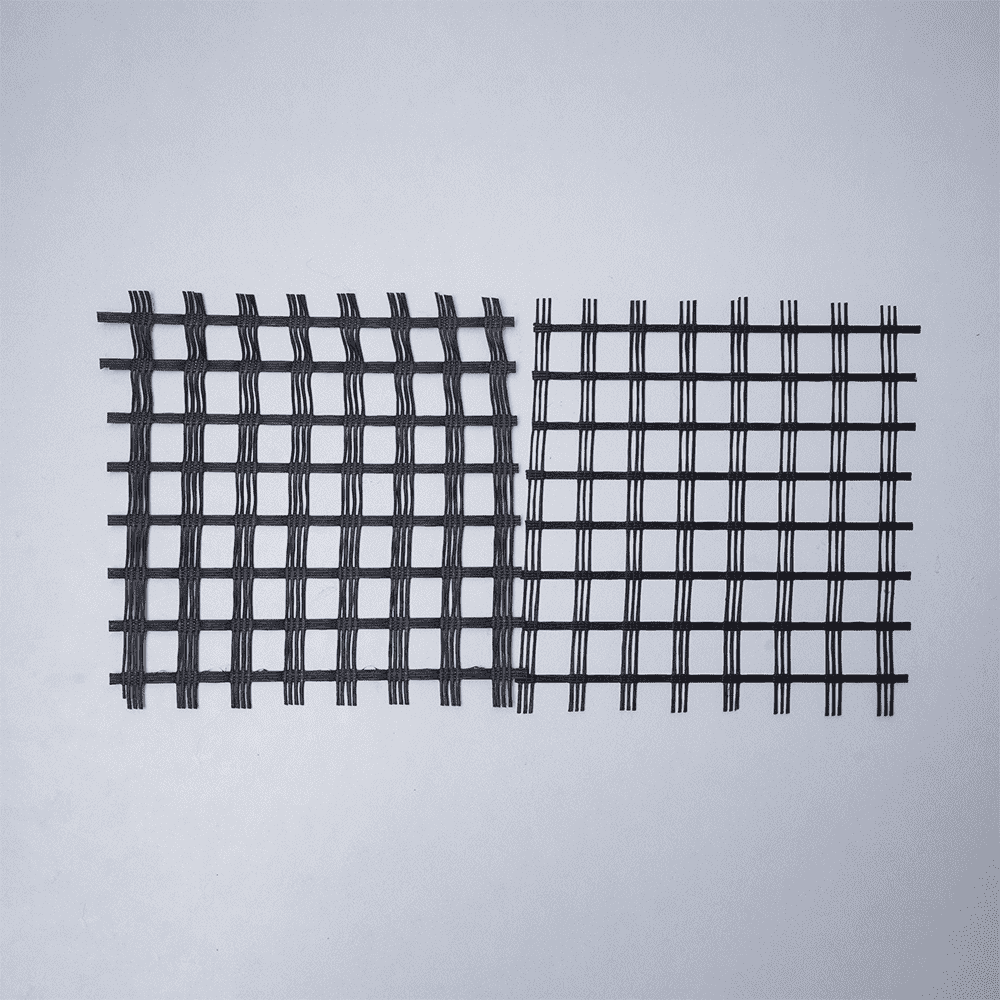

Construction of Fiberglass geogrid