Characteristics and Application Scope of Geocell

Characteristics of Geocell

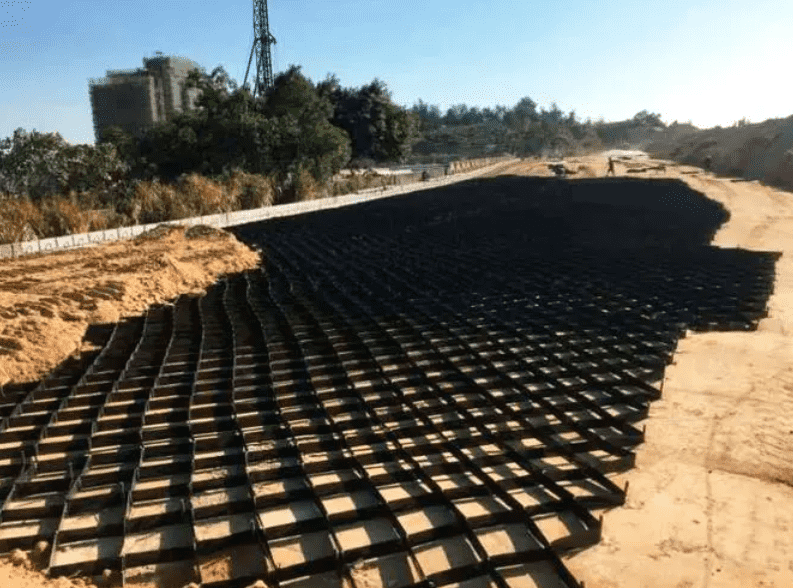

1. Lightweight material, wear-resistant, chemically stable, resistant to light oxygen aging, acid and alkali, suitable for different soil and desert geological conditions.

2. High lateral restrictions and anti slip, anti deformation effectively enhance the bearing capacity of the roadbed and disperse the load.

3. It has high load-bearing capacity and good dynamic performance, with strong erosion resistance.

4. Changing the geometric dimensions such as the height and welding distance of the geocell can meet different engineering needs.

5. Flexible expansion and small transportation volume; Convenient connection and fast construction speed.

6. During construction, local materials can be used to reduce construction costs and are stacked together for easy transportation.

Scope of application of geocell

1. Used to stabilize highway roadbed: It can generate high elastic force and a sturdy roadbed, reducing the thickness of the foundation by more than 50% compared to traditional stone foundations, dispersing and reducing gravity and pressure in contact with the ground horizontally, and can be used in road construction.

2. Used to stabilize railway subgrade: It can prevent lateral movement of crushed stones and grading, making the overall structure more sturdy and preventing water pumping. Even if the foundation is soft, it can prevent overall or partial collapse. In areas with high traffic volume, such as intersections, branch roads, and roundabouts, the service life can be significantly increased.

3. Embankments and retaining walls used to bear the load of gravity: define and strengthen the crushed stones to form a consistent structure, which can block lateral pressure, and can be adjusted independently regardless of strata sliding and condensation. They can support non structural surfaces and natural vegetation layers, and can be designed in a vertical or stepped manner.

4. Used for river management: Three dimensional grids enhance the strength of filling, prevent soil erosion, and increase load capacity, which can reduce the construction cost of shallow rivers and allow the design of crossing rivers to comply with various engineering structures of transportation and soil quality.

5. Used to support pipelines and sewers: The use of honeycomb geogrid chambers eliminates the need to excavate and place a large number of stones as the support structure for pipe bed sewers. Conventional materials are used to form a sturdy and durable overall plate structure, providing flexible protection for the pipeline, reducing minor subsidence caused by prolonged use, making the foundation of the pipeline more sturdy, and preventing local collapse in the long term. This method is simple to construct, reduces excavation, and is more economical and practical for long-distance large transportation pipelines.

6. Hybrid retaining wall for preventing landslides and bearing gravity: Without the use of formwork, a sturdy wall can be created that is firmly integrated with the backfill. Even in situations where traditional gravity structures cannot be used, the backfill can be locally sourced, significantly reducing project costs.

7. For independent walls, docks, flood control embankments, etc.: Independent walls or barrier walls can be quickly constructed, and permeable granular fill embankments or weir walls can be used. If temporary facilities need to be removed, geotechnical cells can also be recycled. It is also widely used in docks, flood embankments, and other important coastal areas.