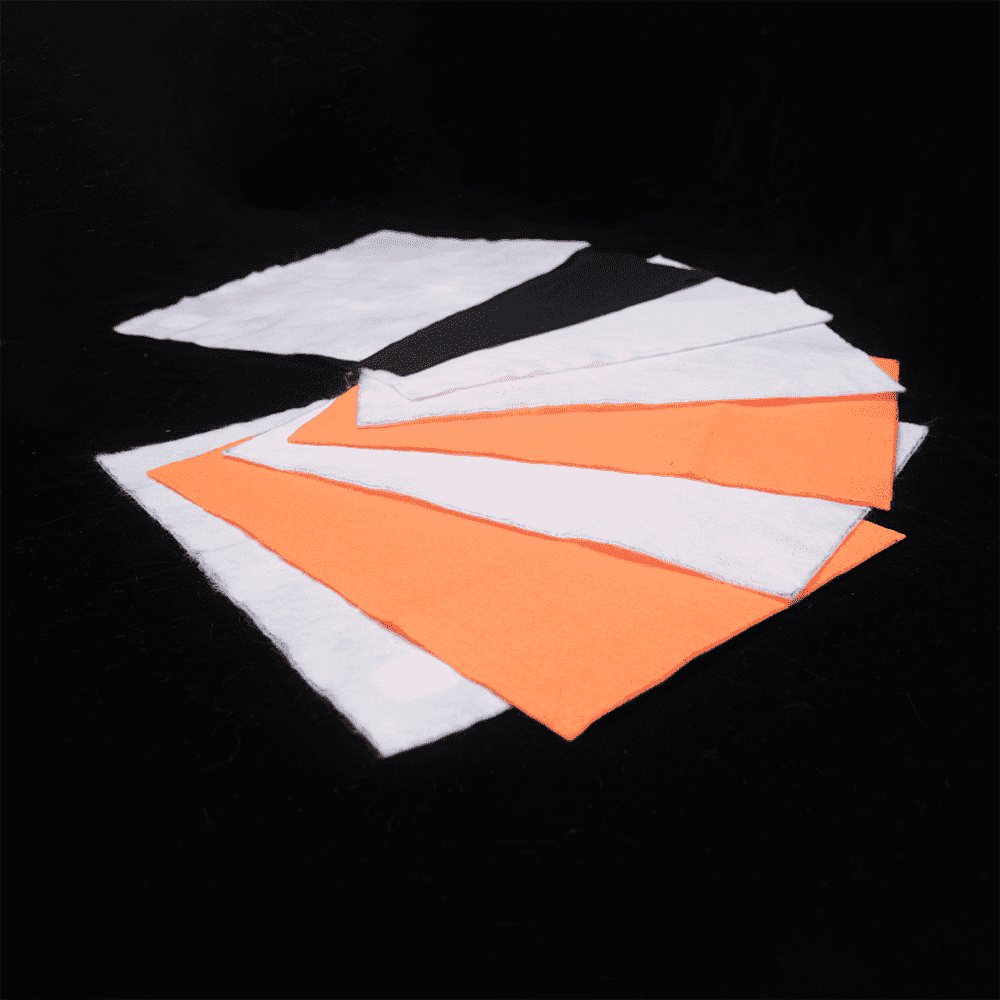

Building materials polyethylene polypropylene non-woven geotextile

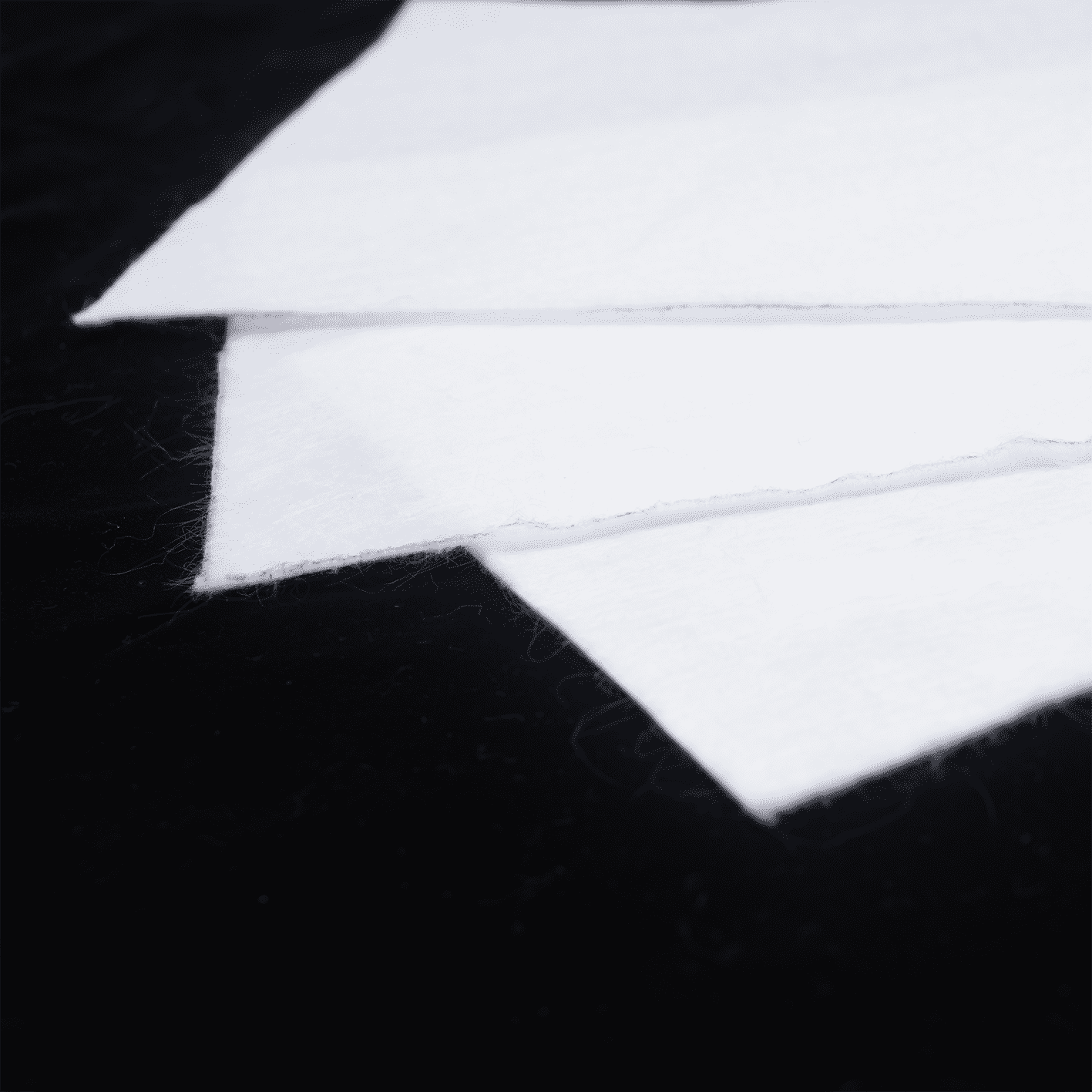

Spunbonded nonwoven

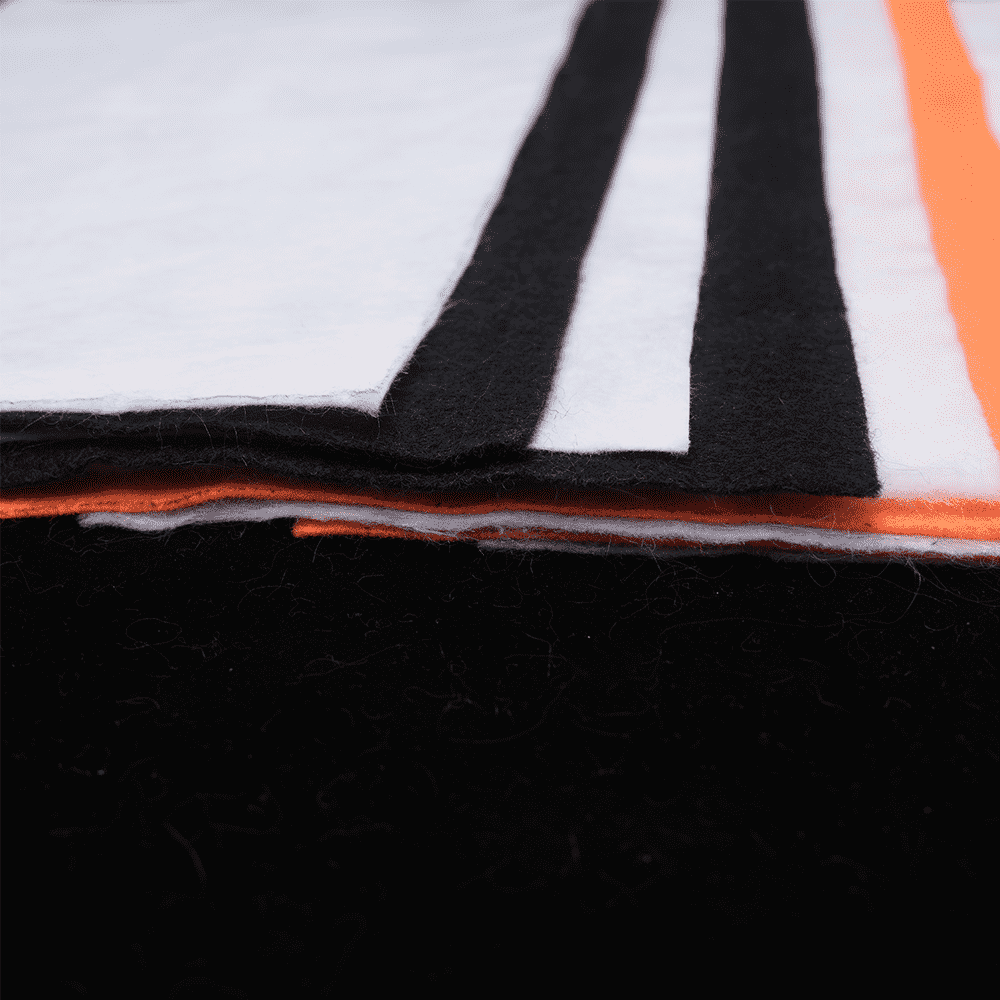

Material: PET/PP

Colors: white, black, green, orange, personalized for statistical coloring

Specification: 100g-800g

Length: 50-100m

Certificate: CE/ISO9001

Support personalized hues and width lengths. Please inform purchaser carrier if there are any different necessities

Leading Geosynthetics Filament geotextile

Product introduction;

Geosynthetic geotextiles are generally used in fields such as civil engineering, groundwork engineering, and environmental engineering. It can be used as a soil reinforcement layer, isolation layer, filter layer, and drainage layer to furnish more resource and protection. It can moreover be used in duties such as roads, railways, embankments, maintaining walls, artificial lakes, and sewage remedy plants.

Product characteristics;

The predominant benefits of geosynthetic geotextile consist of developing groundwork strength, bettering soil stability, stopping soil erosion, supplying drainage function, decreasing settlement, and extending engineering life. However, it want to be referred to that geosynthetic geotextile is totally an auxiliary cloth that needs to be blended with exclusive engineering techniques and components to achieve the satisfactory results

1.Enhancing the energy of soil: Tunnel geotextile can beautify the tensile and shear electrical energy of soil, embellish the stability and bearing practicable of the soil.

2.Drainage and filtration function: Tunnel geotextile has superb drainage and filtration functions, which can efficaciously do away with water and impurities from the soil, give up damage and blockage of the soil layer

Application scope;

3.Reinforce bendy pavement, restore cracks on the road, and stop reflective cracks on the road.

4.The filter layer of water wells, strain alleviation wells or baroclinic pipes in water conservancy initiatives

Specifications

Staple Fiber Needled Non-woven Geotextile Technical Specifications ( GB/T17638-1998) | |||||||||||||

No. | Item | Specifications | Note | ||||||||||

100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 800 | |||

1 | Unit area mass deviation | -8 | -8 | -8 | -8 | -7 | -7 | -7 | -7 | -6 | -6 | -6 |

|

2 | Thickness mm≥ | 0.9 | 1.3 | 1.7 | 2.1 | 2.4 | 2.7 | 3.0 | 3.3 | 3.6 | 4.1 | 5.0 | |

3 | Width deviation | -0.5 | |||||||||||

4 | Breaking strength | 2.5 | 4.5 | 6.5 | 8.0 | 9.5 | 11 | 12.5 | 14.0 | 16.0 | 19.0 | 25.0 | Vertical and horizontal |

5 | Elongation at break % | 20-100 | |||||||||||

6 | CBR bursting strength | 0.3 | 0.6 | 0.8 | 1.2 | 1.4 | 1.8 | 2.1 | 2.4 | 2.7 | 3.2 | 4.0 |

|

7 | Equivalent aperture | 0.07-0.2 |

| ||||||||||

8 | Vertical permeability coefficient | K*(10-1~10-3) | K=1.0-9.9 | ||||||||||

9 | Tear strength | 0.08 | 0.12 | 0.16 | 0.20 | 0.24 | 0.28 | 0.33 | 0.38 | 0.42 | 0.46 | 0.6 | Vertical and horizontal |

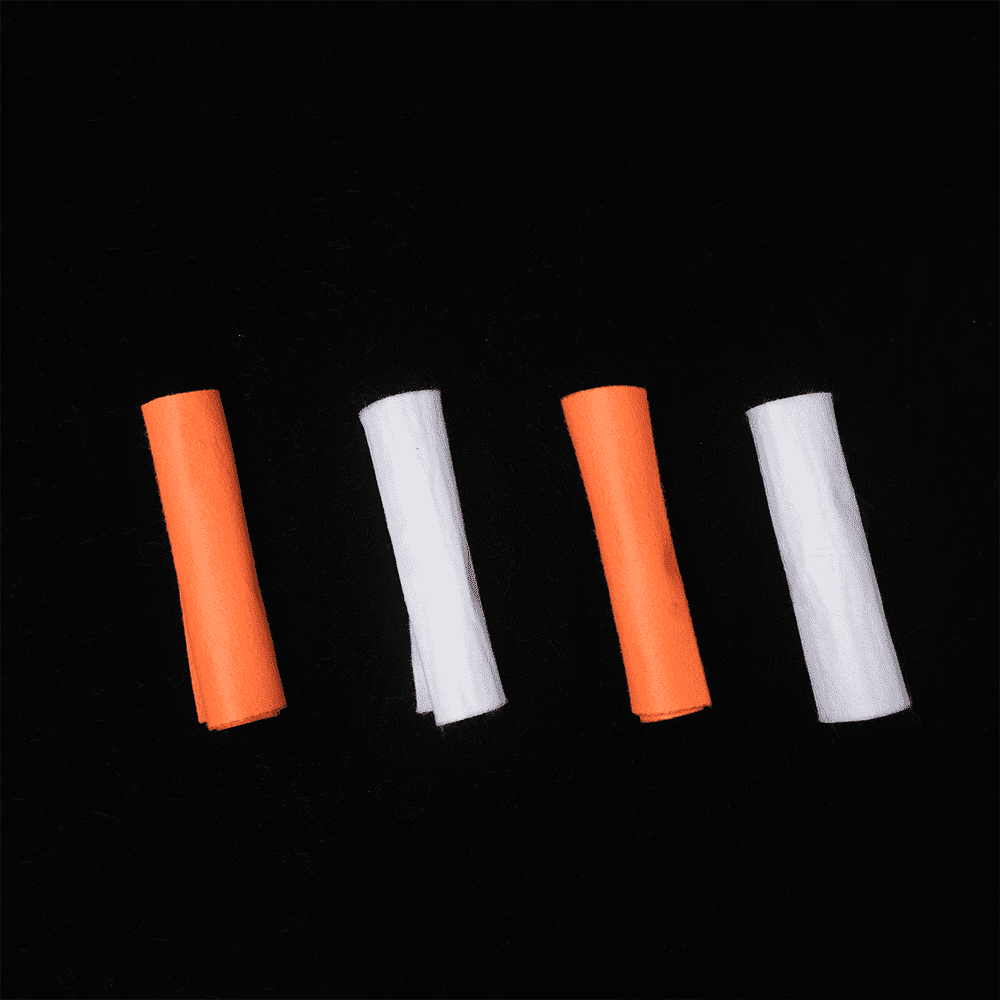

Packing of Top Quality Nonwoven Polypropylene Geotextile Price

You can freely choose PE film or PP woven bag for outer packaging, and there are paper tubes of different sizes inside the product for you to choose freely.

Staple Fiber Needled Non-woven Geotextile Technical Specifications ( GB/T17638-1998) | |||||||||||||

No. | Item | Specifications | Note | ||||||||||

100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 800 | |||

1 | Unit area mass deviation | -8 | -8 | -8 | -8 | -7 | -7 | -7 | -7 | -6 | 6 | -6 |

|

2 | Thickness mm≥ | 0.9 | 1.3 | 1.7 | 2.1 | 2.4 | 2.7 | 3.0 | 3.3 | 3.6 | 4.1 | 5.0 | |

3 | Width deviation | -0.5 | |||||||||||

4 | Breaking strength | 2.5 | 4.5 | 6.5 | 8.0 | 9.5 | 11 | 12.5 | 14.0 | 16.0 | 19.0 | 25.0 | Vertical and horizontal |

5 | Elongation at break % | 20-100 | |||||||||||

6 | CBR bursting strength | 0.3 | 0.6 | 0.8 | 1.2 | 1.4 | 1.8 | 2.1 | 2.4 | 2.7 | 3.2 | 4.0 |

|

7 | Equivalent aperture | 0.07-0.2 |

| ||||||||||

8 | Vertical permeability coefficient | K*(10-1~10-3) | K=1.0-9.9 | ||||||||||

9 | Tear strength | 0.08 | 0.12 | 0.16 | 0.20 | 0.24 | 0.28 | 0.33 | 0.38 | 0.42 | 0.46 | 0.6 | Vertical and horizontal |