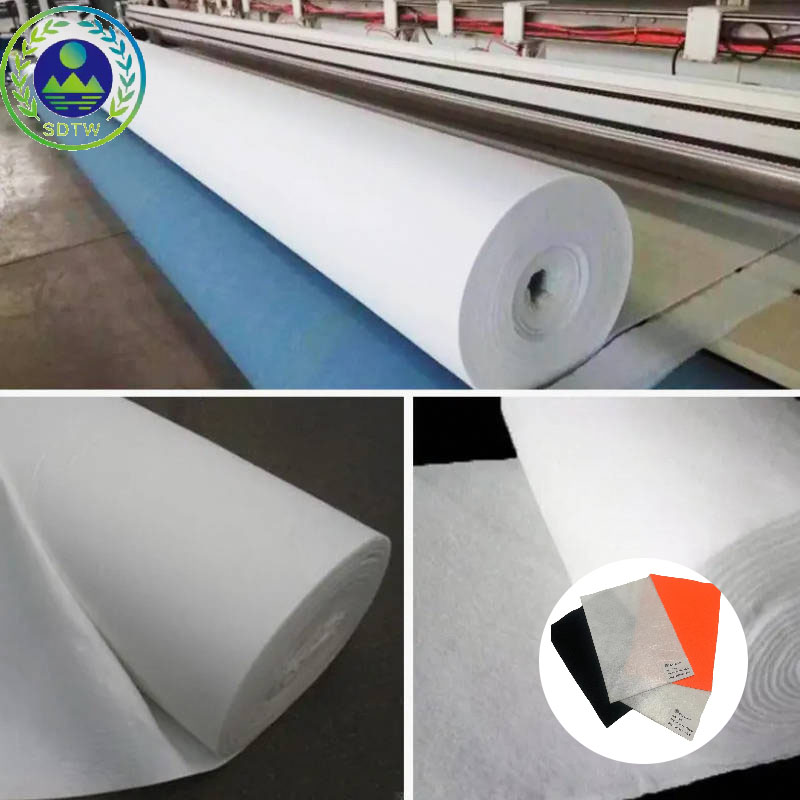

Filament Nonwoven PET Geotextile

Filament Nonwoven PET Geotextile - Using PET as raw material, adopts soften spinning, air-laid and needle-punching consolidation approach to produce geotextiles with third-dimensional pores.High mechanical index, proper creep performance; sturdy corrosion resistance, developing older resistance, extremely good heat resistance, fantastic hydraulic performance.

●Material:Polyester

●Color: White,Black,Orange

●Unit weight:100gsm-800gsm

●Length: 50m-100m

●Width: 1-6.2m

●Certificate: CE /ISO9001

●Type: Needle Punched

Filament Nonwoven PET Geotextile

Product features

●Permeability and plane drainage - the geotextile is thick and needle-punched, has true plane drainage and vertical water permeability, and can then again hold this typical overall performance after many years;

●Creep resistance - the creep resistance of geotextiles is greater than exclusive geotextiles, so the long-term have an effect on is good. It is resistant to the erosion of regular chemical factors in the soil and the corrosion of gasoline and diesel oil;

●Extensibility - Geotextile has a actual elongation cost below a certain stress, so that it can adapt to uneven and irregular base surfaces;

Application:

●Drainage of artificially filled sports field foundation.

●It is used to strengthen weak foundations in highways (including temporary roads), railways, embankments, earth-rock dams, airports, sports fields and other projects.

●As the reinforcement in the backfill of the maintaining wall, or as the panel for anchoring the maintaining wall. Build wrapped maintaining partitions or abutments.

●Strengthen the bendy pavement, restore cracks on the road, and stop reflective cracks on the pavement.

Product implementation standards: national standard (GB/T 17639-2008)

Filament Spunbonded Needled Non-woven Geotextile Technical Specifications | ||||||||||

Item | Index | |||||||||

Index breaking strength(KN/m) | 4.5 | 7.5 | 10 | 15 | 20 | 25 | 30 | 40 | 50 | |

1 | Vertical and horizontal rupture strength / (KN/ m) | 4.5 | 7.5 | 10 | 15 | 20 | 25 | 30 | 40 | 50 |

2 | Vertical and horizontal standard strength corresponding to elongation % | 40-80 | ||||||||

3 | CBR bursting strength /KN | 0.8 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 |

4 | Vertical and horizontal tearing strength /KN | 0.14 | 0.21 | 0.28 | 0.42 | 0.56 | 0.70 | 0.82 | 1.10 | 1.25 |

5 | Equivalent aperture O90(95)>/mm | 0.05-0.20 | ||||||||

6 | Vertical permeability coefficient | K*(10-1~10-3)and K=1.0~9.9 | ||||||||

7 | Thickness / mm≥ | 0.8 | 1.2 | 1.6 | 2.2 | 2.8 | 3.4 | 4.2 | 5.5 | 6.8 |

8 | Width deviation | -0.5 | ||||||||

9 | Unit area mass deviation | -5 | ||||||||

Packing of Filament Nonwoven PET Geotextile

You can freely choose PE film or PP woven bag for outer packaging, and there are paper tubes of different sizes inside the product for you to choose freely.

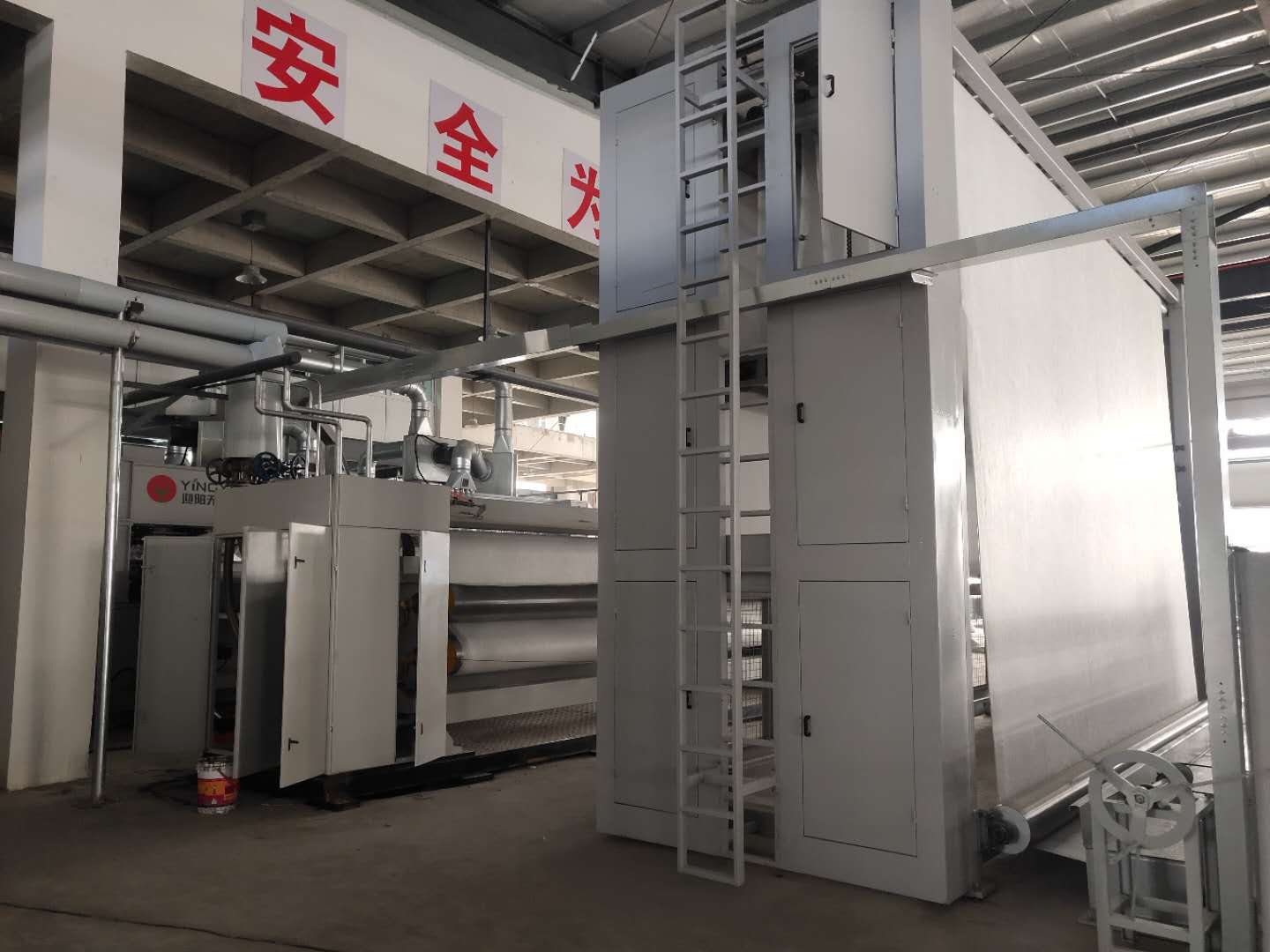

Strength of the company

The agency has independent geotextile manufacturing equipment, knowledgeable technicians, a large manufacturing team and a professional after-sales team. The annual output of geotextiles exceeds 30 million square meters. Products are widely used in landfills, artificial lakes, rivers, canals, subways, basements, highways, railways, tunnels and special projects. Certified as an excellent cloth distributor in the United States. Exported overseas many times.