Filament PET Geotextile

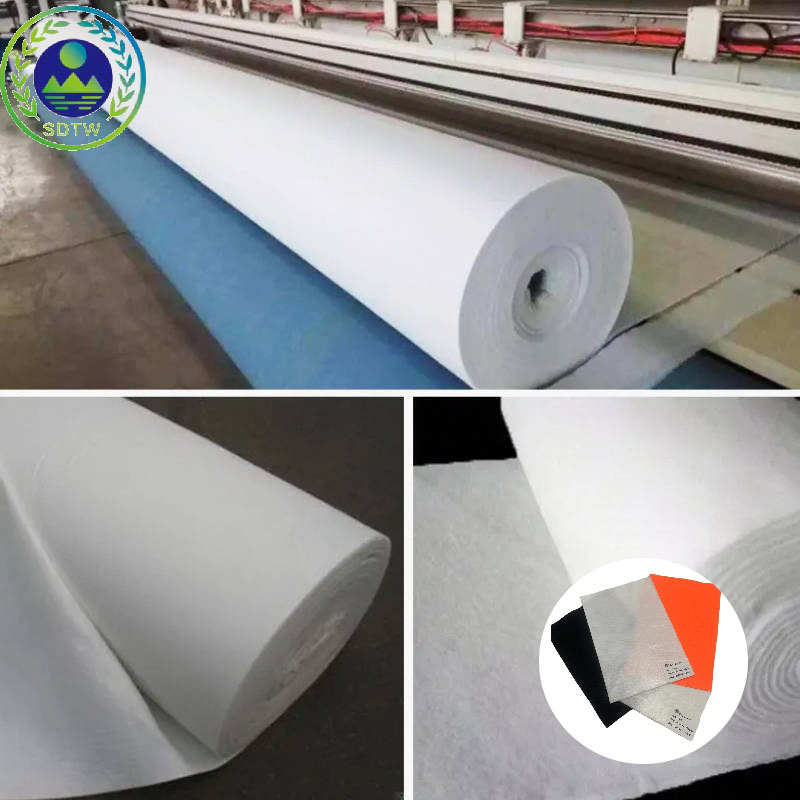

Filament PET Geotextile - Using PET as uncooked material, adopts soften spinning, air-laid and needle-punching consolidation technique to produce geotextiles with 3-dimensional pores.High mechanical index, true creep performance; sturdy corrosion resistance, growing older resistance, remarkable warmth resistance, gorgeous hydraulic performance.

●Material:Polyester

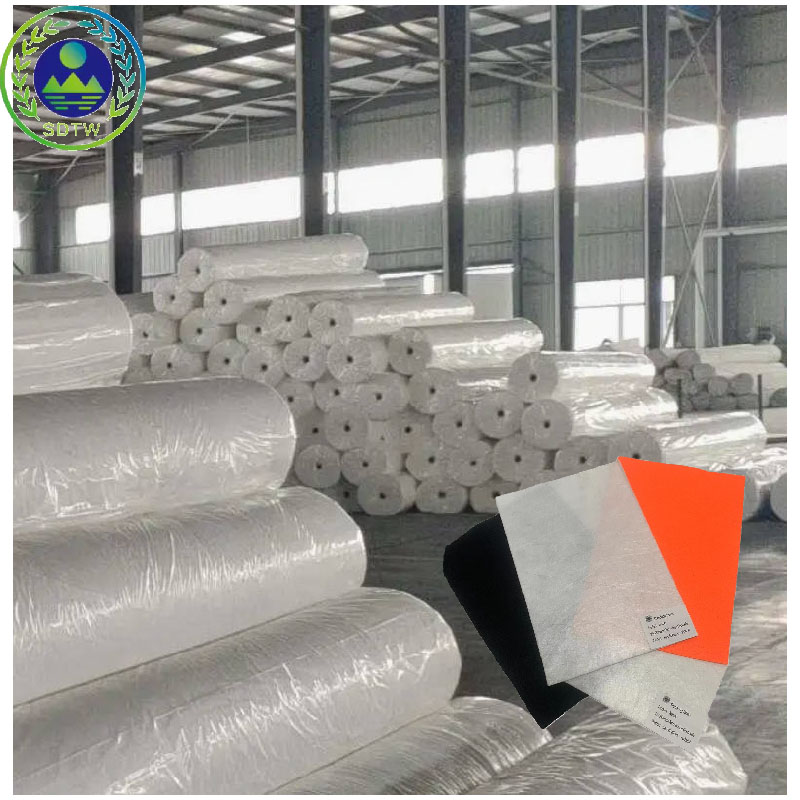

●Color: White,Black,Orange

●Unit weight:100gsm-800gsm

●Length: 50m-100m

●Width: 1-6.2m

●Certificate: CE /ISO9001

●Type: Needle Punched

Filament PET Geotextile

Product features

●Strength - Under the equal weight specification, the tensile electrical energy in all instructions is greater than tremendous needle-punched non-woven fabrics;

●Anti-ultraviolet moderate - has a very excessive anti-ultraviolet ability;

●Extremely excessive temperature resistance time-honored standard overall performance - excessive temperature resistance up to 230 ℃, on the different hand continues structural integrity and one-of-a-kind bodily residences beneath excessive temperature;

Application:

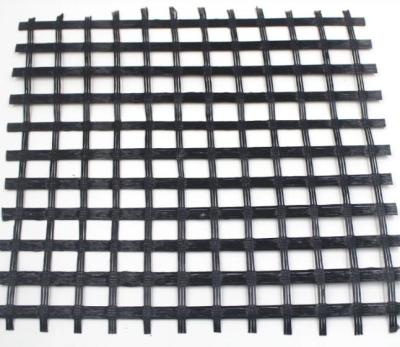

●Increase the steadiness of gravel slope and strengthened soil, stop soil erosion and freezing harm of soil at low temperature.

●The isolation layer between the street ballast and the subgrade, or the isolation layer between the subgrade and the smooth foundation.

●Isolation layer between synthetic fill, rockfill or fabric discipline and foundation, isolation between extraordinary permafrost layers, reverse filtration and reinforcement.

●The filter layer of the preliminary upstream dam floor of the ash storage dam or tailings dam, and the filter layer of the drainage device in the backfill soil of the preserving wall.

Product implementation standards: national standard (GB/T 17639-2008)

| Filament Spunbonded Needled Non-woven Geotextile Technical Specifications | ||||||||||

| Item | Index | |||||||||

| Index breaking strength(KN/m) | 4.5 | 7.5 | 10 | 15 | 20 | 25 | 30 | 40 | 50 | |

| 1 | Vertical and horizontal rupture strength / (KN/ m) | 4.5 | 7.5 | 10 | 15 | 20 | 25 | 30 | 40 | 50 |

| 2 | Vertical and horizontal standard strength corresponding to elongation % | 40-80 | ||||||||

| 3 | CBR bursting strength /KN | 0.8 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 |

| 4 | Vertical and horizontal tearing strength /KN | 0.14 | 0.21 | 0.28 | 0.42 | 0.56 | 0.70 | 0.82 | 1.10 | 1.25 |

| 5 | Equivalent aperture O90(95)>/mm | 0.05-0.20 | ||||||||

| 6 | Vertical permeability coefficient | K*(10-1~10-3)and K=1.0~9.9 | ||||||||

| 7 | Thickness / mm≥ | 0.8 | 1.2 | 1.6 | 2.2 | 2.8 | 3.4 | 4.2 | 5.5 | 6.8 |

| 8 | Width deviation | -0.5 | ||||||||

| 9 | Unit area mass deviation | -5 | ||||||||

Packing of Filament PET Geotextile

You can freely choose PE film or PP woven bag for outer packaging, and there are paper tubes of different sizes inside the product for you to choose freely.

Strength of the company

The company has complete geotextile production equipment, high-quality technical personnel, a large production team and a professional after-sales team. The annual output of geotextiles exceeds 30 million square meters. Products are widely used in special projects such as landfills, artificial lakes, rivers, canals, subways, basements, expressways, railways, and tunnels. Certified Extraordinary Materials Distributor in the United States. It has been exported to Europe and Southeast Asia many times.