Geotextile High Quality Fabrics Non Woven PET Geotextile

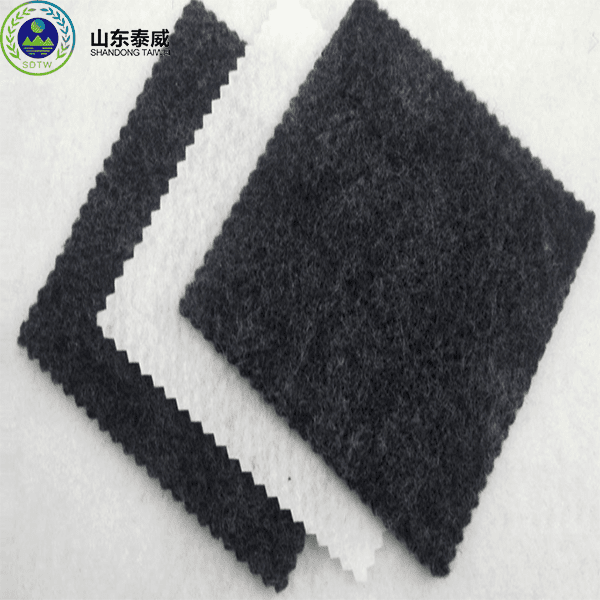

Geotextile High Quality Fabrics Non Woven PET Geotextile-Staple fiber needle-punched nonwoven geotextiles use PET staple fibers as the main raw material and are produced by non-woven technology. Good flexibility, corrosion resistance and oxidation resistance.

●Material: PET fiber

●Color: white, black, gray

●Length: 50m-100m

●Width: 0.5-6m

●Certificate: CE/ISO9001

●Type: Acupuncture

Geotextile High Quality Fabrics Non Woven PET Geotextile

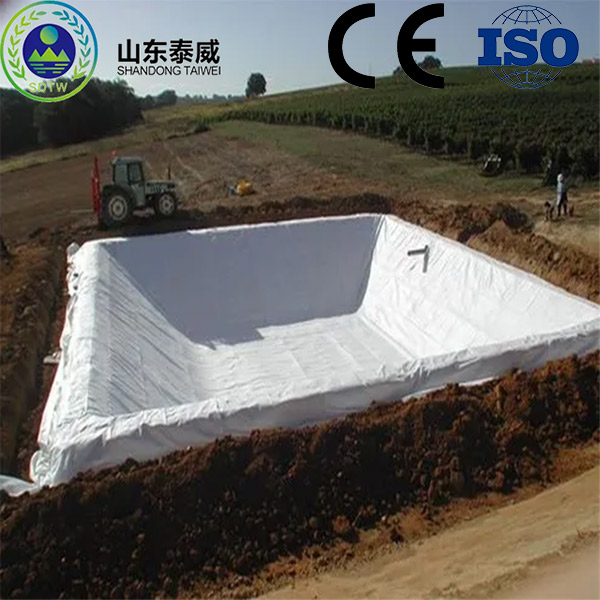

PET non-woven geotextiles have good anti-seepage and corrosion resistance, so that geotextiles are widely used in railways, highways, tunnels, and coastal tidal flat projects for isolation, reverse filtration, reinforcement, protection, and drainage.

Product Features:

Good flexibility and corrosion resistance

Good anti-microbial properties, no damage to microorganisms and moths;

Has good water permeability and filtration performance

Because of its light weight and can be packed according to certain requirements, it is very convenient for transportation, storage and construction.

Application:

The product has excellent water permeability, filterability and durability, and can be widely used in railways, highways, sports halls, dams, hydraulic structures, tunnels, coastal tidal flats, reclamation, environmental protection and other projects.

Function:

Utilize the good air permeability and water permeability of geotextiles to let water flow through, thereby effectively retaining the lost sand.

Widely used in cement concrete pavement and roadbed, light weight, high strength, high tensile strength, suitable for both hard and flexible pavement, long service life, helps to prevent road reflection cracks;

Use geotextiles to enhance the tensile strength and deformation resistance of the soil, enhance the stability of the building structure, and improve the quality of the soil.

Specifications

Staple Fiber Needled Non-woven Geotextile Technical Specifications ( GB/T17638-1998) | |||||||||||||

No. | Item | Specifications | Note | ||||||||||

100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 800 | |||

1 | Unit area mass deviation | -8 | -8 | -8 | -8 | -7 | -7 | -7 | -7 | -6 | -6 | -6 |

|

2 | Thickness mm≥ | 0.9 | 1.3 | 1.7 | 2.1 | 2.4 | 2.7 | 3.0 | 3.3 | 3.6 | 4.1 | 5.0 | |

3 | Width deviation | -0.5 | |||||||||||

4 | Breaking strength | 2.5 | 4.5 | 6.5 | 8.0 | 9.5 | 11 | 12.5 | 14.0 | 16.0 | 19.0 | 25.0 | Vertical and horizontal |

5 | Elongation at break % | 20-100 | |||||||||||

6 | CBR bursting strength | 0.3 | 0.6 | 0.8 | 1.2 | 1.4 | 1.8 | 2.1 | 2.4 | 2.7 | 3.2 | 4.0 |

|

7 | Equivalent aperture | 0.07-0.2 |

| ||||||||||

8 | Vertical permeability coefficient | K*(10-1~10-3) | K=1.0-9.9 | ||||||||||

9 | Tear strength | 0.08 | 0.12 | 0.16 | 0.20 | 0.24 | 0.28 | 0.33 | 0.38 | 0.42 | 0.46 | 0.6 | Vertical and horizontal |

Packing of Geotextile High Quality Fabrics Non Woven PET Geotextile

You can freely choose PE film or PP woven bag for outer packaging, and there are paper tubes of different sizes inside the product for you to choose freely.

FAQ

1. Who are we?

Headquartered in Shandong, China, we are a professional enterprise engaged in the R&D, production and sales of geosynthetics.

2. How can we guarantee the quality?

Always a pre-production sample before mass production; Always a final inspection before shipment;

3. What can you buy from us?

Geotextiles, HDPE geomembranes, composite geotextiles, geocells, and geogrids.

4. Why should you buy from us not from other suppliers?

With an annual output of 6,000 tons of geotextiles, it is close to the port, with convenient transportation and a professional after-sales team.

5. What services can we provide?

Accepted delivery terms: FOB, CFR, CIF;

Accepted payment currencies: USD, RMB;

Accepted payment methods: T/T, Paypal;

Staple Fiber Needled Non-woven Geotextile Technical Specifications ( GB/T17638-1998) | |||||||||||||

No. | Item | Specifications | Note | ||||||||||

100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 800 | |||

1 | Unit area mass deviation | -8 | -8 | -8 | -8 | -7 | -7 | -7 | -7 | -6 | 6 | -6 |

|

2 | Thickness mm≥ | 0.9 | 1.3 | 1.7 | 2.1 | 2.4 | 2.7 | 3.0 | 3.3 | 3.6 | 4.1 | 5.0 | |

3 | Width deviation | -0.5 | |||||||||||

4 | Breaking strength | 2.5 | 4.5 | 6.5 | 8.0 | 9.5 | 11 | 12.5 | 14.0 | 16.0 | 19.0 | 25.0 | Vertical and horizontal |

5 | Elongation at break % | 20-100 | |||||||||||

6 | CBR bursting strength | 0.3 | 0.6 | 0.8 | 1.2 | 1.4 | 1.8 | 2.1 | 2.4 | 2.7 | 3.2 | 4.0 |

|

7 | Equivalent aperture | 0.07-0.2 |

| ||||||||||

8 | Vertical permeability coefficient | K*(10-1~10-3) | K=1.0-9.9 | ||||||||||

9 | Tear strength | 0.08 | 0.12 | 0.16 | 0.20 | 0.24 | 0.28 | 0.33 | 0.38 | 0.42 | 0.46 | 0.6 | Vertical and horizontal |

Related Products

Submitted successfully

We will contact you as soon as possible

Submitted successfully

We will contact you as soon as possible