Staple Fiber PET Geotextile

Staple Fiber PET Geotextile-The staple fiber needle-punched nonwoven geotextile is made of PP or PET, which has high strength, corrosion resistance and convenient construction. Because the material is light and soft, it is convenient for transportation, laying and construction;

●Material: PET fiber

●Color: white, black, gray

●Length: 50m-100m

●Width: 0.5-6m

●Certificate: CE/ISO9001

●Type: Acupuncture

Staple Fiber PET Geotextile

PET non-woven geotextiles have good anti-seepage and corrosion resistance, so that geotextiles are widely used in railways, highways, tunnels, and coastal tidal flat projects for isolation, reverse filtration, reinforcement, protection, and drainage.

Product Features:

The network is not easy to block - the network structure formed by the amorphous fibrous tissue has strain and mobility.

Geotextile has good water conductivity, it can form a drainage channel inside the soil, and discharge excess liquid and gas in the soil structure.

Geotextile has good water conductivity, it can form a drainage channel inside the soil, and discharge excess liquid and gas in the soil structure.

Made of chemical fibers such as polypropylene or polyester, it has good acid and alkali resistance, corrosion resistance, insect resistance and oxidation resistance.

Application:

Staple Fiber PET Geotextile-The product has high-quality water permeability, filterability and durability, and can be broadly used in railways, highways, sports activities halls, dams, hydraulic structures, tunnels, coastal tidal flats, reclamation, environmental safety and different projects.

Function:

Easy construction, good application effect

The surface is rough and not easy to slide. When laying, the rough side of the surface after special treatment is facing upwards to increase the friction coefficient and increase the bonding force of the surface layer to prevent being rolled up and damaged by the wheels during construction, and at the same time, it can prevent vehicles and paver from slipping on the cloth ;

Anti-ultraviolet, anti-freeze, anti-chemical corrosion, anti-biological damage;

Specifications

Staple Fiber Needled Non-woven Geotextile Technical Specifications ( GB/T17638-1998) | |||||||||||||

No. | Item | Specifications | Note | ||||||||||

100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 800 | |||

1 | Unit area mass deviation | -8 | -8 | -8 | -8 | -7 | -7 | -7 | -7 | -6 | -6 | -6 |

|

2 | Thickness mm≥ | 0.9 | 1.3 | 1.7 | 2.1 | 2.4 | 2.7 | 3.0 | 3.3 | 3.6 | 4.1 | 5.0 | |

3 | Width deviation | -0.5 | |||||||||||

4 | Breaking strength | 2.5 | 4.5 | 6.5 | 8.0 | 9.5 | 11 | 12.5 | 14.0 | 16.0 | 19.0 | 25.0 | Vertical and horizontal |

5 | Elongation at break % | 20-100 | |||||||||||

6 | CBR bursting strength | 0.3 | 0.6 | 0.8 | 1.2 | 1.4 | 1.8 | 2.1 | 2.4 | 2.7 | 3.2 | 4.0 |

|

7 | Equivalent aperture | 0.07-0.2 |

| ||||||||||

8 | Vertical permeability coefficient | K*(10-1~10-3) | K=1.0-9.9 | ||||||||||

9 | Tear strength | 0.08 | 0.12 | 0.16 | 0.20 | 0.24 | 0.28 | 0.33 | 0.38 | 0.42 | 0.46 | 0.6 | Vertical and horizontal |

Packing of Staple Fiber PET Geotextile

You can freely choose PE film or PP woven bag for outer packaging, and there are paper tubes of different sizes inside the product for you to choose freely.

FAQ

Q1: How to get a sample?

A: We can provide you with free samples for quality inspection, and the shipping cost needs to be borne by you.

Q2: What is the MOQ?

A: The MOQ is usually USD 3000.

Q3: What is your payment terms?

A: Payment: 30% deposit paid by T/T to confirm order, 70% balance paid by T/T before delivery.

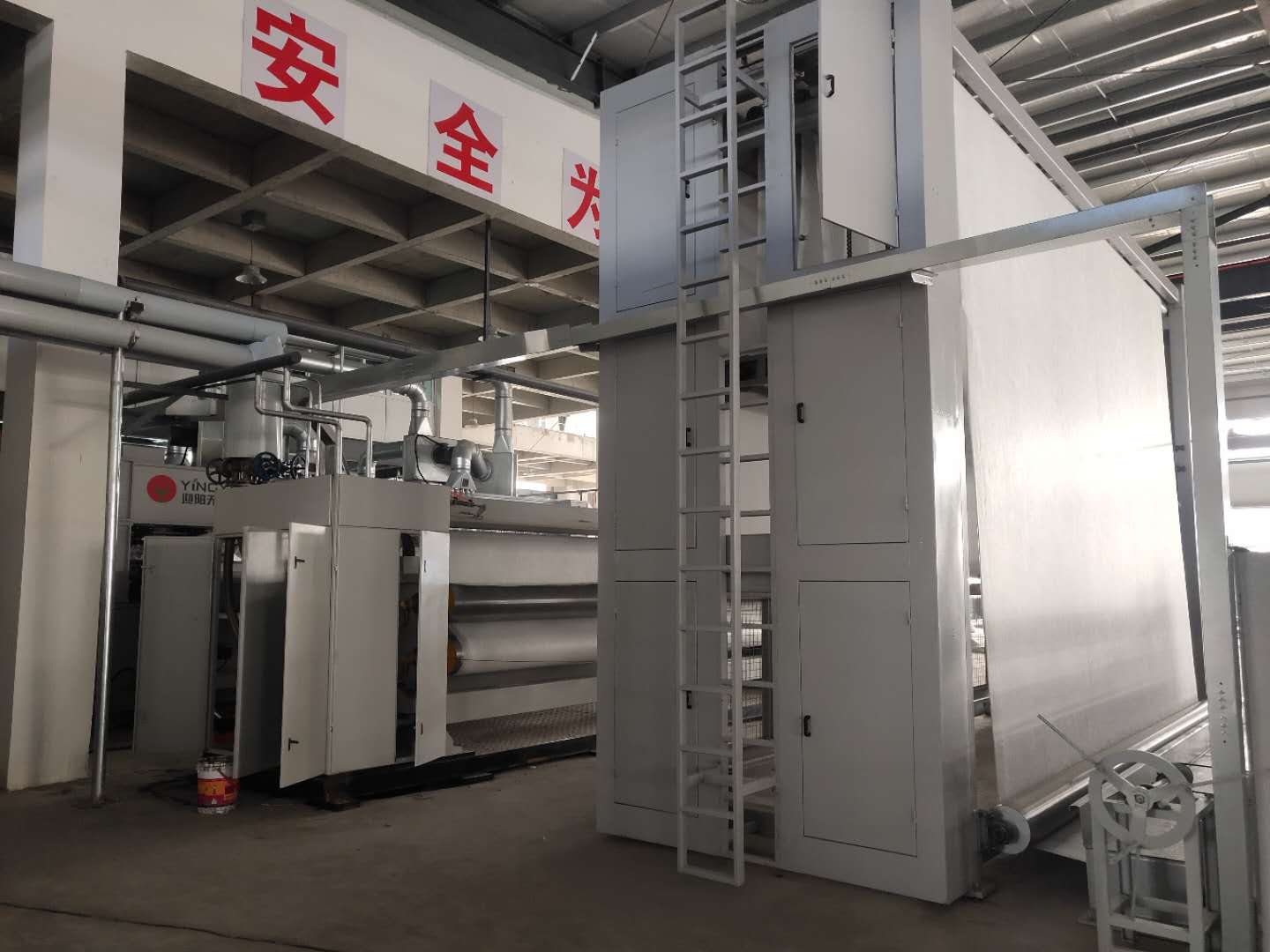

Q4: Can we visit your factory to check the goods of the order?

A: Welcome to visit our factory to check the quality. We sincerely hope to establish an honest business relationship.

Staple Fiber Needled Non-woven Geotextile Technical Specifications ( GB/T17638-1998) | |||||||||||||

No. | Item | Specifications | Note | ||||||||||

100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 800 | |||

1 | Unit area mass deviation | -8 | -8 | -8 | -8 | -7 | -7 | -7 | -7 | -6 | 6 | -6 |

|

2 | Thickness mm≥ | 0.9 | 1.3 | 1.7 | 2.1 | 2.4 | 2.7 | 3.0 | 3.3 | 3.6 | 4.1 | 5.0 | |

3 | Width deviation | -0.5 | |||||||||||

4 | Breaking strength | 2.5 | 4.5 | 6.5 | 8.0 | 9.5 | 11 | 12.5 | 14.0 | 16.0 | 19.0 | 25.0 | Vertical and horizontal |

5 | Elongation at break % | 20-100 | |||||||||||

6 | CBR bursting strength | 0.3 | 0.6 | 0.8 | 1.2 | 1.4 | 1.8 | 2.1 | 2.4 | 2.7 | 3.2 | 4.0 |

|

7 | Equivalent aperture | 0.07-0.2 |

| ||||||||||

8 | Vertical permeability coefficient | K*(10-1~10-3) | K=1.0-9.9 | ||||||||||

9 | Tear strength | 0.08 | 0.12 | 0.16 | 0.20 | 0.24 | 0.28 | 0.33 | 0.38 | 0.42 | 0.46 | 0.6 | Vertical and horizontal |