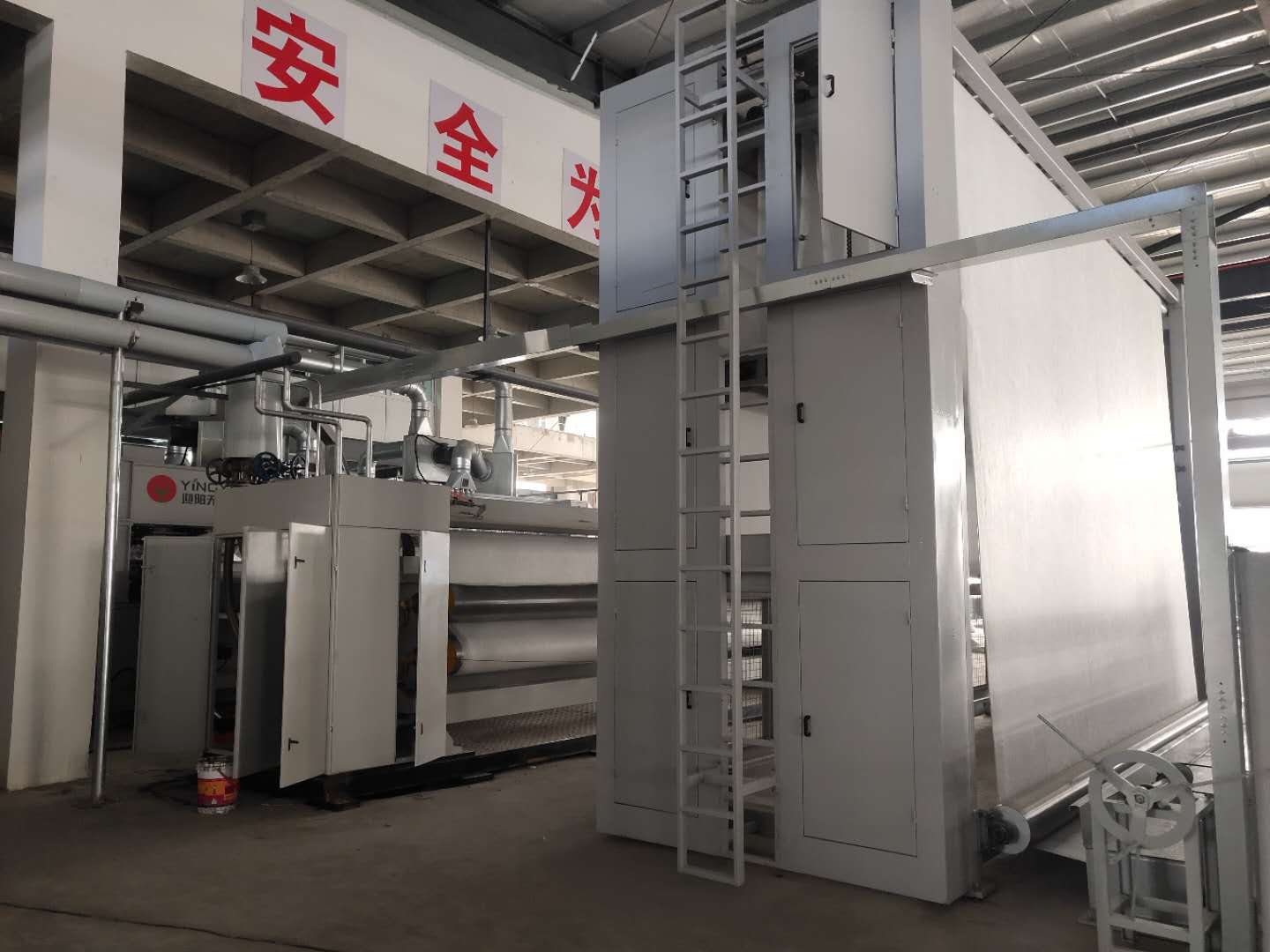

Staple Fiber Needled Nonwoven Polypropylene Geotextile

Staple Fiber Needled Nonwoven Polypropylene Geotextile-Staple fiber needle-punched nonwoven geotextiles use PP or PET quick fibers as the primary uncooked fabric and are produced with the aid of non-woven technology. They have the features of isolation, filtration, drainage, reinforcement, and maintenance.

●Material: Polypropylene fiber

●Color: white, black, gray

●Length: 50m-100m

●Width: 0.5-6m

●Certificate: CE/ISO9001

●Type: Acupuncture

Staple Fiber Needled Nonwoven Polypropylene Geotextile

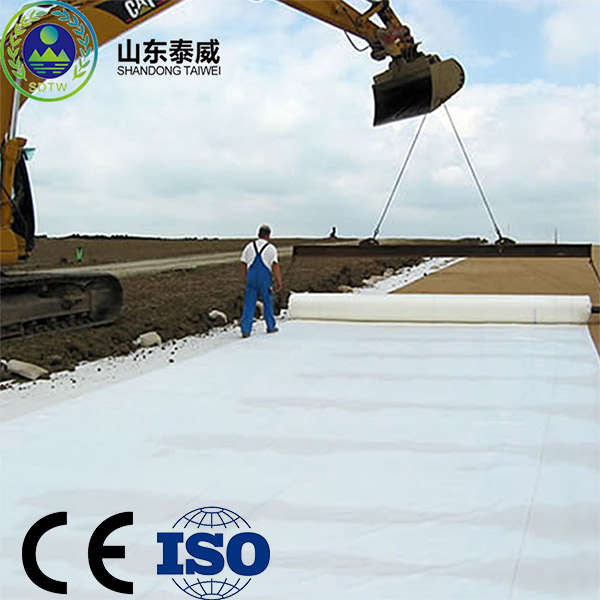

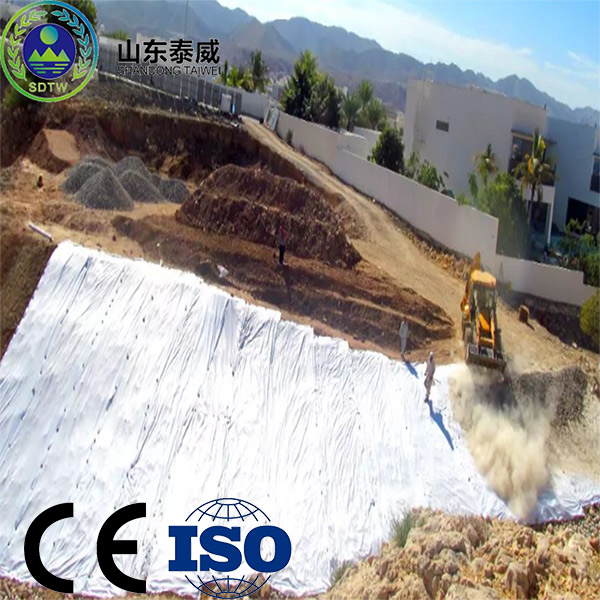

PP non-woven geotextiles have good anti-seepage and corrosion resistance, so that geotextiles are widely used in railways, highways, tunnels, and coastal tidal flat projects for isolation, reverse filtration, reinforcement, protection, and drainage.

Product Features:

Effectively diffuse, transfer or decompose the concentrated stress to prevent the soil from being damaged by external forces.

Prevent mixing between upper and lower layers of sand, soil and concrete.

The mesh is not easy to block - the mesh structure formed by the amorphous fibrous tissue has strain and mobility.

High water permeability - under the pressure of soil and water, it can still maintain good water permeability

Application:

Staple Fiber Needled Nonwoven Polypropylene Geotextile-The product has excellent water permeability, filterability and durability, and can be widely used in railways, highways, sports halls, dams, hydraulic structures, tunnels, coastal tidal flats, reclamation, environmental protection and other projects.

Function:

Widely used in the reinforcement of asphalt pavement, cement concrete pavement and roadbed. It can be applied to both hard and flexible road surfaces, which can reduce the cost compared with traditional road surfaces, prolong the service life, and prevent road reflection cracks;

The thickness of the product is suitable, easy to combine with asphalt pavement, and form an isolation layer after combining with sticky layer oil, which has the function of waterproof and heat preservation;

Anti-ultraviolet, anti-freeze, anti-chemical corrosion and anti-biological damage;

Specifications

Staple Fiber Needled Non-woven Geotextile Technical Specifications ( GB/T17638-1998) | |||||||||||||

No. | Item | Specifications | Note | ||||||||||

100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 800 | |||

1 | Unit area mass deviation | -8 | -8 | -8 | -8 | -7 | -7 | -7 | -7 | -6 | -6 | -6 |

|

2 | Thickness mm≥ | 0.9 | 1.3 | 1.7 | 2.1 | 2.4 | 2.7 | 3.0 | 3.3 | 3.6 | 4.1 | 5.0 | |

3 | Width deviation | -0.5 | |||||||||||

4 | Breaking strength | 2.5 | 4.5 | 6.5 | 8.0 | 9.5 | 11 | 12.5 | 14.0 | 16.0 | 19.0 | 25.0 | Vertical and horizontal |

5 | Elongation at break % | 20-100 | |||||||||||

6 | CBR bursting strength | 0.3 | 0.6 | 0.8 | 1.2 | 1.4 | 1.8 | 2.1 | 2.4 | 2.7 | 3.2 | 4.0 |

|

7 | Equivalent aperture | 0.07-0.2 |

| ||||||||||

8 | Vertical permeability coefficient | K*(10-1~10-3) | K=1.0-9.9 | ||||||||||

9 | Tear strength | 0.08 | 0.12 | 0.16 | 0.20 | 0.24 | 0.28 | 0.33 | 0.38 | 0.42 | 0.46 | 0.6 | Vertical and horizontal |

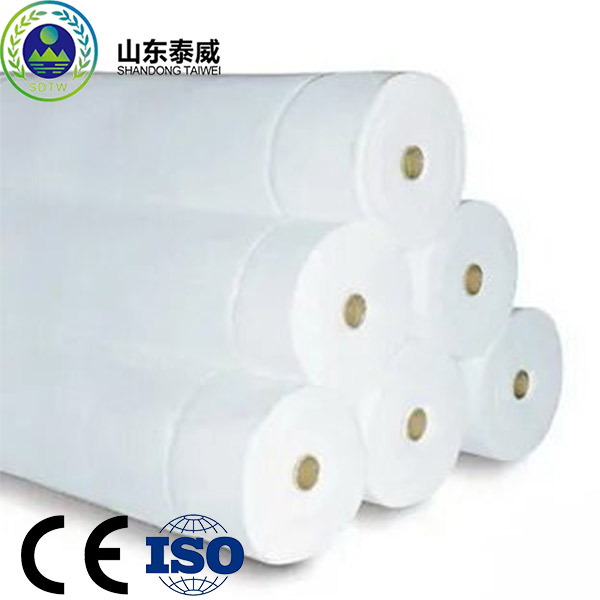

Packing of Staple Fiber Needled Nonwoven Polypropylene Geotextile

You can freely choose PE film or PP woven bag for outer packaging, and there are paper tubes of different sizes inside the product for you to choose freely.

FAQ

Q: Can you do OEM?

Answer: Of course you can. We can produce products according to your requirements.

Q: Do you provide samples? Is it free or extra?

A: Yes, we can provide samples for free, but do not pay for shipping.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. Or if the goods are not in stock it is 10-15 days, it is based on quantity.

Q: What's your payment terms?

A: Payment: 30% deposit paid by T/T to confirm order, 70% balance paid by T/T before delivery.

Q:What services can we provide?

A:Accepted delivery terms: FOB, CFR, CIF;

Accepted payment currencies: USD, RMB;

Accepted payment methods: T/T, PayPal;

Language: English, Chinese

Staple Fiber Needled Non-woven Geotextile Technical Specifications ( GB/T17638-1998) | |||||||||||||

No. | Item | Specifications | Note | ||||||||||

100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 800 | |||

1 | Unit area mass deviation | -8 | -8 | -8 | -8 | -7 | -7 | -7 | -7 | -6 | 6 | -6 |

|

2 | Thickness mm≥ | 0.9 | 1.3 | 1.7 | 2.1 | 2.4 | 2.7 | 3.0 | 3.3 | 3.6 | 4.1 | 5.0 | |

3 | Width deviation | -0.5 | |||||||||||

4 | Breaking strength | 2.5 | 4.5 | 6.5 | 8.0 | 9.5 | 11 | 12.5 | 14.0 | 16.0 | 19.0 | 25.0 | Vertical and horizontal |

5 | Elongation at break % | 20-100 | |||||||||||

6 | CBR bursting strength | 0.3 | 0.6 | 0.8 | 1.2 | 1.4 | 1.8 | 2.1 | 2.4 | 2.7 | 3.2 | 4.0 |

|

7 | Equivalent aperture | 0.07-0.2 |

| ||||||||||

8 | Vertical permeability coefficient | K*(10-1~10-3) | K=1.0-9.9 | ||||||||||

9 | Tear strength | 0.08 | 0.12 | 0.16 | 0.20 | 0.24 | 0.28 | 0.33 | 0.38 | 0.42 | 0.46 | 0.6 | Vertical and horizontal |