Geotextile laying for highways and tunnels

Spunbonded nonwoven

Material: PET/PP

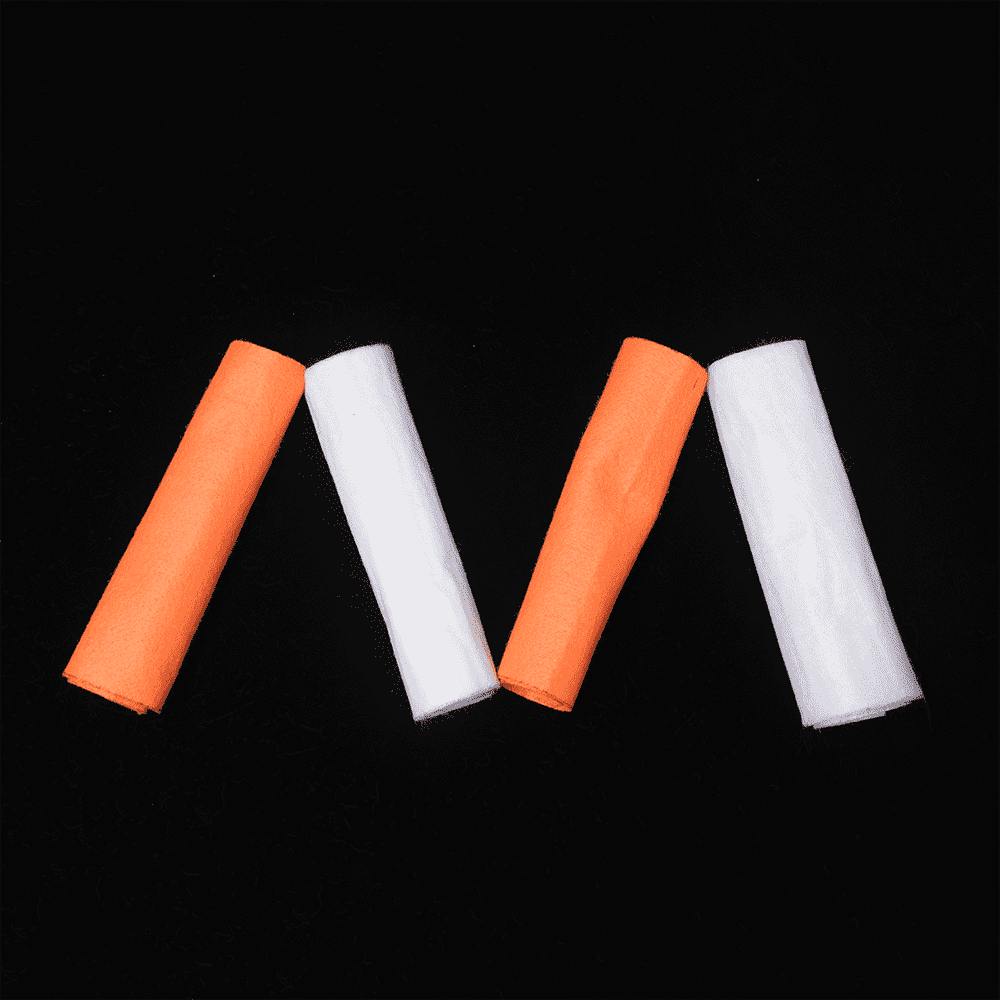

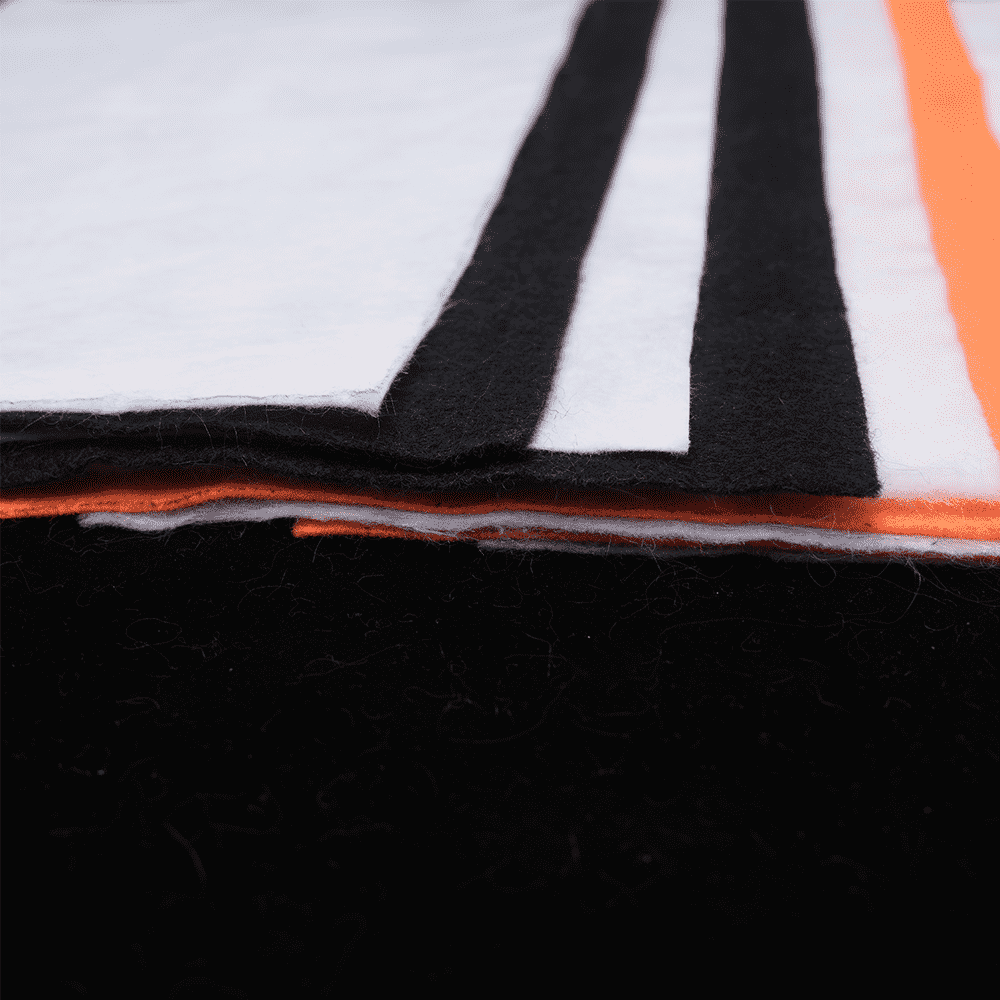

Colors: white, black, green, orange, personalized for statistical coloring

Specification: 100g-800g

Length: 50-100m

Certificate: CE/ISO9001

Support personalized hues and width lengths. Please inform purchaser carrier if there are any different necessities

Leading Geosynthetics Filament geotextile

Product introduction;

Geotextile is a water-permeable geosynthetic material made of synthetic fibers by means of needle punching or weaving. Geotextile is one of the new geosynthetic materials.

Product characteristics;

The predominant advantages of geosynthetic geotextile consist of growing groundwork strength, bettering soil stability, stopping soil erosion, imparting drainage function, reducing settlement, and extending engineering life. However, it wish to be referred to that geosynthetic geotextile is barring a doubt an auxiliary material that needs to be blended with one of

a kind engineering methods and aspects to acquire the satisfactory outcomes

1. High strength, maintaining full strength and elongation in wet and dry conditions.

2. Corrosion-resistant, can resist corrosion for a long time in soil and water with different pH levels.

3. Good water permeability. There are gaps between fibers, so it has good water permeability.

4. Good anti-microbial properties and will not be damaged by microorganisms or insects.

5. Convenient construction. Because the material is light and soft, it is convenient to transport, lay and construct.

Application scope;

l. Filter material for soil layer separation

2. Drainage materials for reservoirs and mines, and drainage materials for high-rise building foundations

3. Anti-scouring materials for river dams and slope protection

4. Reinforcing materials for railways, highways and airport runways, and reinforcement materials for road construction in swamp areas

5. Anti-frost and anti-freeze insulation materials

6. Anti-crack materials for asphalt pavement.

Specifications

Staple Fiber Needled Non-woven Geotextile Technical Specifications ( GB/T17638-1998) | |||||||||||||

No. | Item | Specifications | Note | ||||||||||

100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 800 | |||

1 | Unit area mass deviation | -8 | -8 | -8 | -8 | -7 | -7 | -7 | -7 | -6 | -6 | -6 |

|

2 | Thickness mm≥ | 0.9 | 1.3 | 1.7 | 2.1 | 2.4 | 2.7 | 3.0 | 3.3 | 3.6 | 4.1 | 5.0 | |

3 | Width deviation | -0.5 | |||||||||||

4 | Breaking strength | 2.5 | 4.5 | 6.5 | 8.0 | 9.5 | 11 | 12.5 | 14.0 | 16.0 | 19.0 | 25.0 | Vertical and horizontal |

5 | Elongation at break % | 20-100 | |||||||||||

6 | CBR bursting strength | 0.3 | 0.6 | 0.8 | 1.2 | 1.4 | 1.8 | 2.1 | 2.4 | 2.7 | 3.2 | 4.0 |

|

7 | Equivalent aperture | 0.07-0.2 |

| ||||||||||

8 | Vertical permeability coefficient | K*(10-1~10-3) | K=1.0-9.9 | ||||||||||

9 | Tear strength | 0.08 | 0.12 | 0.16 | 0.20 | 0.24 | 0.28 | 0.33 | 0.38 | 0.42 | 0.46 | 0.6 | Vertical and horizontal |

Packing of Top Quality Nonwoven Polypropylene Geotextile Price

You can freely choose PE film or PP woven bag for outer packaging, and there are paper tubes of different sizes inside the product for you to choose freely.

Staple Fiber Needled Non-woven Geotextile Technical Specifications ( GB/T17638-1998) | |||||||||||||

No. | Item | Specifications | Note | ||||||||||

100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 800 | |||

1 | Unit area mass deviation | -8 | -8 | -8 | -8 | -7 | -7 | -7 | -7 | -6 | 6 | -6 |

|

2 | Thickness mm≥ | 0.9 | 1.3 | 1.7 | 2.1 | 2.4 | 2.7 | 3.0 | 3.3 | 3.6 | 4.1 | 5.0 | |

3 | Width deviation | -0.5 | |||||||||||

4 | Breaking strength | 2.5 | 4.5 | 6.5 | 8.0 | 9.5 | 11 | 12.5 | 14.0 | 16.0 | 19.0 | 25.0 | Vertical and horizontal |

5 | Elongation at break % | 20-100 | |||||||||||

6 | CBR bursting strength | 0.3 | 0.6 | 0.8 | 1.2 | 1.4 | 1.8 | 2.1 | 2.4 | 2.7 | 3.2 | 4.0 |

|

7 | Equivalent aperture | 0.07-0.2 |

| ||||||||||

8 | Vertical permeability coefficient | K*(10-1~10-3) | K=1.0-9.9 | ||||||||||

9 | Tear strength | 0.08 | 0.12 | 0.16 | 0.20 | 0.24 | 0.28 | 0.33 | 0.38 | 0.42 | 0.46 | 0.6 | Vertical and horizontal |