Polypropylene Road And Railway Filter Staple Fiber Geotextile

Spunbonded nonwoven

Material: PET/PP

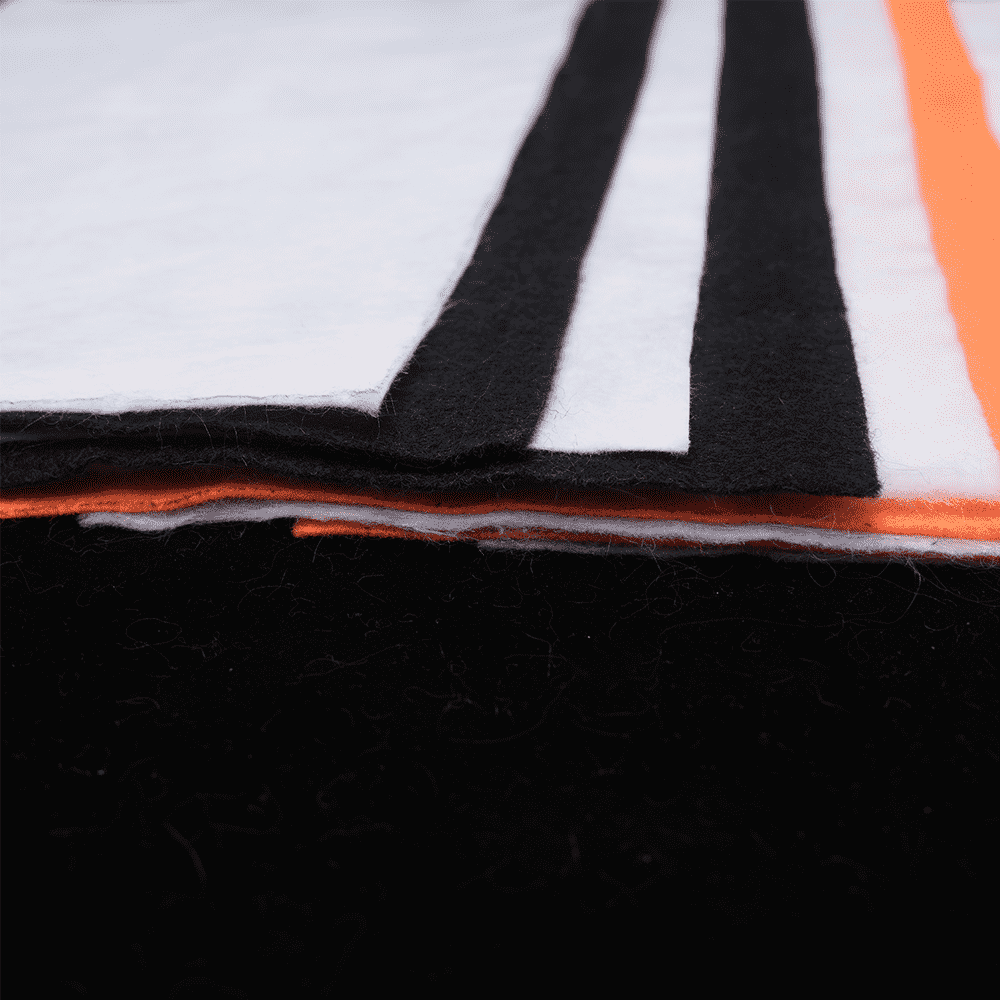

Colors: white, black, green, orange, personalized for statistical coloring

Specification: 80g-800g

Length: 50-200m

Certificate: CE/ISO9001

Support personalized hues and width lengths. Please inform purchaser carrier if there are any different necessities

Polypropylene Road And Railway Filter Staple Fiber Geotextile

Product introduction;

Short fiber geotextile is a kind of geosynthetic cloth often used in civil engineering and geotechnical applications. It is made from artificial fibers that are routinely bonded or needle-punched collectively to shape a steady cloth structure.

Product characteristics;

1.Filtration: The material shape of quick fiber geotextile permits water to ignore thru whilst keeping soil particles. This filtration property makes it beneficial in purposes such as drainage structures and erosion control, the place it helps in stopping the clogging of soils and advertising high quality water flow.

2.Separation: Short fiber geotextile acts as a separator between special soil layers or substances with specific characteristics. By stopping the mixing of these layers, it continues their man or woman integrity and enhances typical stability. Common examples encompass its use in avenue construction, the place it separates the subgrade from the asphalt or concrete layers.

3.Reinforcement: The excessive tensile power of brief fiber geotextile gives reinforcement to soil and development materials. It will increase their load-bearing potential and helps in controlling settlements or deformations. This property is in particular beneficial in purposes such as slope stability, protecting walls, and landfill liners.

4.Protection: Short fiber geotextile can be used to shield geomembranes, waterproofing layers, and different touchy substances from mechanical harm for the duration of development or long-term use. It acts as a cushioning layer, stopping punctures or abrasions.

5.Durability: Made from artificial fibers, brief fiber geotextile presents resistance to degradation from UV radiation, chemicals, and organic factors. It has a lengthy lifespan that ensures its effectiveness over time.

Application scope;

1.Road and railway construction: Used as a separation and filtration layer in avenue bases, subgrades, and railway ballast systems.

2.Erosion control: Used in shoreline protection, river embankments, and steep slope stabilization to forestall soil erosion and promote vegetation growth.

3.Drainage systems: Incorporated in subsurface drainage systems, septic drain fields, and stormwater administration amenities for environment friendly water drainage and filtration.

4.Landfill and waste management: Used as a defensive barrier in landfill liners, caps, and waste containment structures to forestall soil contamination.

5.Landscape and agriculture: Applied in landscaping initiatives for weed control, soil stabilization, and reinforcement. Used in agriculture for erosion control, filtration in irrigation systems, and safety of pond liners.

Specifications

Staple Fiber Needled Non-woven Geotextile Technical Specifications ( GB/T17638-1998) | |||||||||||||

No. | Item | Specifications | Note | ||||||||||

100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 800 | |||

1 | Unit area mass deviation | -8 | -8 | -8 | -8 | -7 | -7 | -7 | -7 | -6 | -6 | -6 |

|

2 | Thickness mm≥ | 0.9 | 1.3 | 1.7 | 2.1 | 2.4 | 2.7 | 3.0 | 3.3 | 3.6 | 4.1 | 5.0 | |

3 | Width deviation | -0.5 | |||||||||||

4 | Breaking strength | 2.5 | 4.5 | 6.5 | 8.0 | 9.5 | 11 | 12.5 | 14.0 | 16.0 | 19.0 | 25.0 | Vertical and horizontal |

5 | Elongation at break % | 20-100 | |||||||||||

6 | CBR bursting strength | 0.3 | 0.6 | 0.8 | 1.2 | 1.4 | 1.8 | 2.1 | 2.4 | 2.7 | 3.2 | 4.0 |

|

7 | Equivalent aperture | 0.07-0.2 |

| ||||||||||

8 | Vertical permeability coefficient | K*(10-1~10-3) | K=1.0-9.9 | ||||||||||

9 | Tear strength | 0.08 | 0.12 | 0.16 | 0.20 | 0.24 | 0.28 | 0.33 | 0.38 | 0.42 | 0.46 | 0.6 | Vertical and horizontal |

Packing of Top Quality Nonwoven Polypropylene Geotextile Price

You can freely choose PE film or PP woven bag for outer packaging, and there are paper tubes of different sizes inside the product for you to choose freely.

Staple Fiber Needled Non-woven Geotextile Technical Specifications ( GB/T17638-1998) | |||||||||||||

No. | Item | Specifications | Note | ||||||||||

100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 800 | |||

1 | Unit area mass deviation | -8 | -8 | -8 | -8 | -7 | -7 | -7 | -7 | -6 | 6 | -6 |

|

2 | Thickness mm≥ | 0.9 | 1.3 | 1.7 | 2.1 | 2.4 | 2.7 | 3.0 | 3.3 | 3.6 | 4.1 | 5.0 | |

3 | Width deviation | -0.5 | |||||||||||

4 | Breaking strength | 2.5 | 4.5 | 6.5 | 8.0 | 9.5 | 11 | 12.5 | 14.0 | 16.0 | 19.0 | 25.0 | Vertical and horizontal |

5 | Elongation at break % | 20-100 | |||||||||||

6 | CBR bursting strength | 0.3 | 0.6 | 0.8 | 1.2 | 1.4 | 1.8 | 2.1 | 2.4 | 2.7 | 3.2 | 4.0 |

|

7 | Equivalent aperture | 0.07-0.2 |

| ||||||||||

8 | Vertical permeability coefficient | K*(10-1~10-3) | K=1.0-9.9 | ||||||||||

9 | Tear strength | 0.08 | 0.12 | 0.16 | 0.20 | 0.24 | 0.28 | 0.33 | 0.38 | 0.42 | 0.46 | 0.6 | Vertical and horizontal |