Tunnel drainage short-filament geotextile

Spunbonded nonwoven

Material: PET/PP

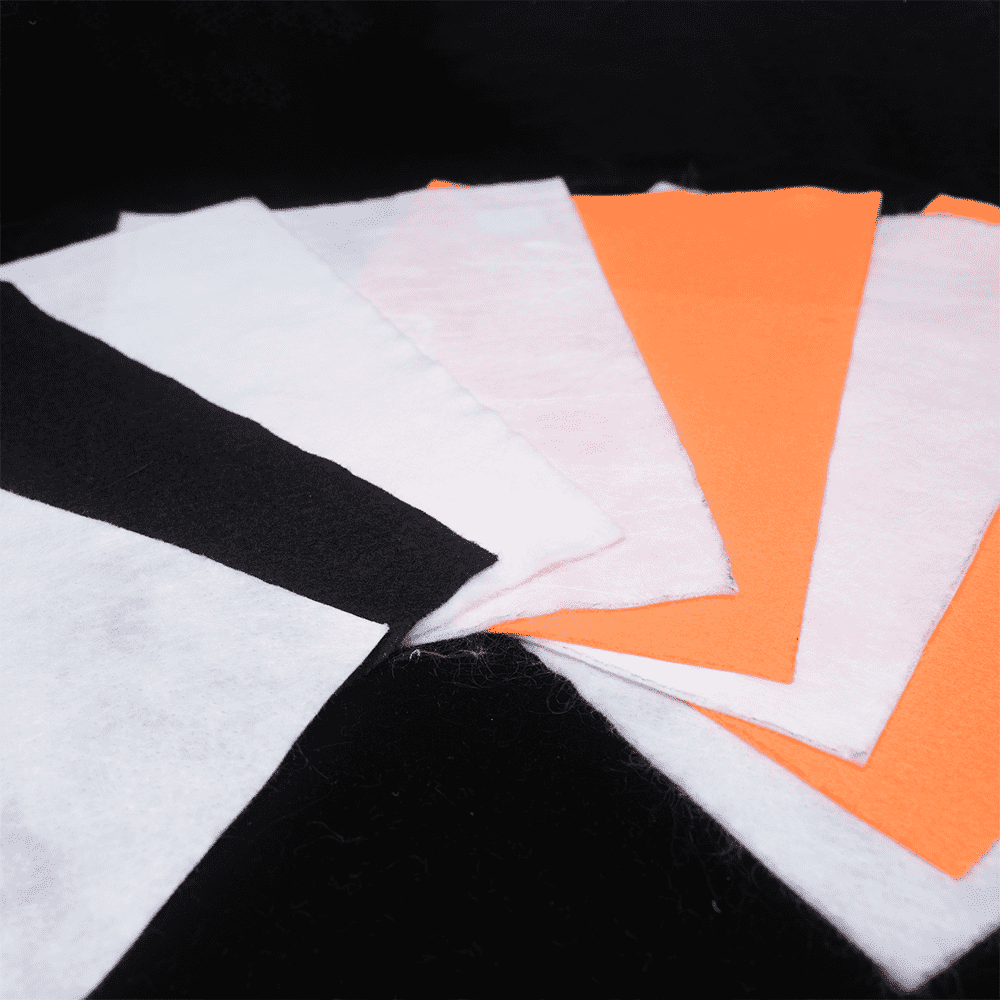

Colors: white, black, green, orange, personalized for statistical coloringWidth:1-7m

Specification: 100g-800g

Length: Customized according to customer needs

Certificate: CE/ISO9001

Support personalized hues and width lengths. Please inform purchaser carrier if there are any different necessities

Port specific Short silk geotextile

Product introduction;

Short-fiber geotextile (short-fiber needle-punched geotextile) has good mechanical properties, good water permeability, and can resist corrosion and aging. It has the functions of isolation, reverse filtration, drainage, protection, stabilization, reinforcement, etc., and can adapt to unevenness. The uneven base layer can resist damage caused by external construction forces, has small creep, and can still maintain its original functions under long-term loads.

Product characteristics;

1. Utilize the good air permeability and water permeability of geotextile to allow water to pass through, thereby effectively intercepting sand and soil loss.

2. Geotextile has good water conductivity. It can form drainage channels inside the soil to drain excess liquid and gas out of the soil structure.

3. Use geotextiles to enhance the tensile strength and deformation resistance of the soil and enhance the stability of the building structure to improve the quality of the soil.

4. Effectively diffuse, transfer or decompose concentrated stress to prevent soil from being damaged by external forces.

5. Prevent the mixing of sand, soil and concrete between the upper and lower layers.

6. The mesh is not easily blocked - the mesh structure formed by the amorphous fibrous tissue is adaptable and mobile.

7. High water permeability—can still maintain good water permeability under the pressure of soil and water

8. Corrosion resistance - Made of polypropylene or polyester and other chemical fibers as raw materials, it is acid and alkali resistant, non-corrosive, non-moth-eaten, and anti-oxidation

9. Simple construction - light weight, easy to use, simple construction

Application scope;

Short-filament geotextiles can be used as drainage materials for reservoirs and mines, as well as for drainage of high-rise building foundations. It can be used as an anti-scouring material for river floors and slope protection. It can be widely used in railways, highways, sports halls, dams, hydraulic construction, tunnels, coastal beaches, reclamation, environmental protection and other projects.

Specifications

Staple Fiber Needled Non-woven Geotextile Technical Specifications ( GB/T17638-1998) | |||||||||||||

No. | Item | Specifications | Note | ||||||||||

100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 800 | |||

1 | Unit area mass deviation | -8 | -8 | -8 | -8 | -7 | -7 | -7 | -7 | -6 | -6 | -6 |

|

2 | Thickness mm≥ | 0.9 | 1.3 | 1.7 | 2.1 | 2.4 | 2.7 | 3.0 | 3.3 | 3.6 | 4.1 | 5.0 | |

3 | Width deviation | -0.5 | |||||||||||

4 | Breaking strength | 2.5 | 4.5 | 6.5 | 8.0 | 9.5 | 11 | 12.5 | 14.0 | 16.0 | 19.0 | 25.0 | Vertical and horizontal |

5 | Elongation at break % | 20-100 | |||||||||||

6 | CBR bursting strength | 0.3 | 0.6 | 0.8 | 1.2 | 1.4 | 1.8 | 2.1 | 2.4 | 2.7 | 3.2 | 4.0 |

|

7 | Equivalent aperture | 0.07-0.2 |

| ||||||||||

8 | Vertical permeability coefficient | K*(10-1~10-3) | K=1.0-9.9 | ||||||||||

9 | Tear strength | 0.08 | 0.12 | 0.16 | 0.20 | 0.24 | 0.28 | 0.33 | 0.38 | 0.42 | 0.46 | 0.6 | Vertical and horizontal |

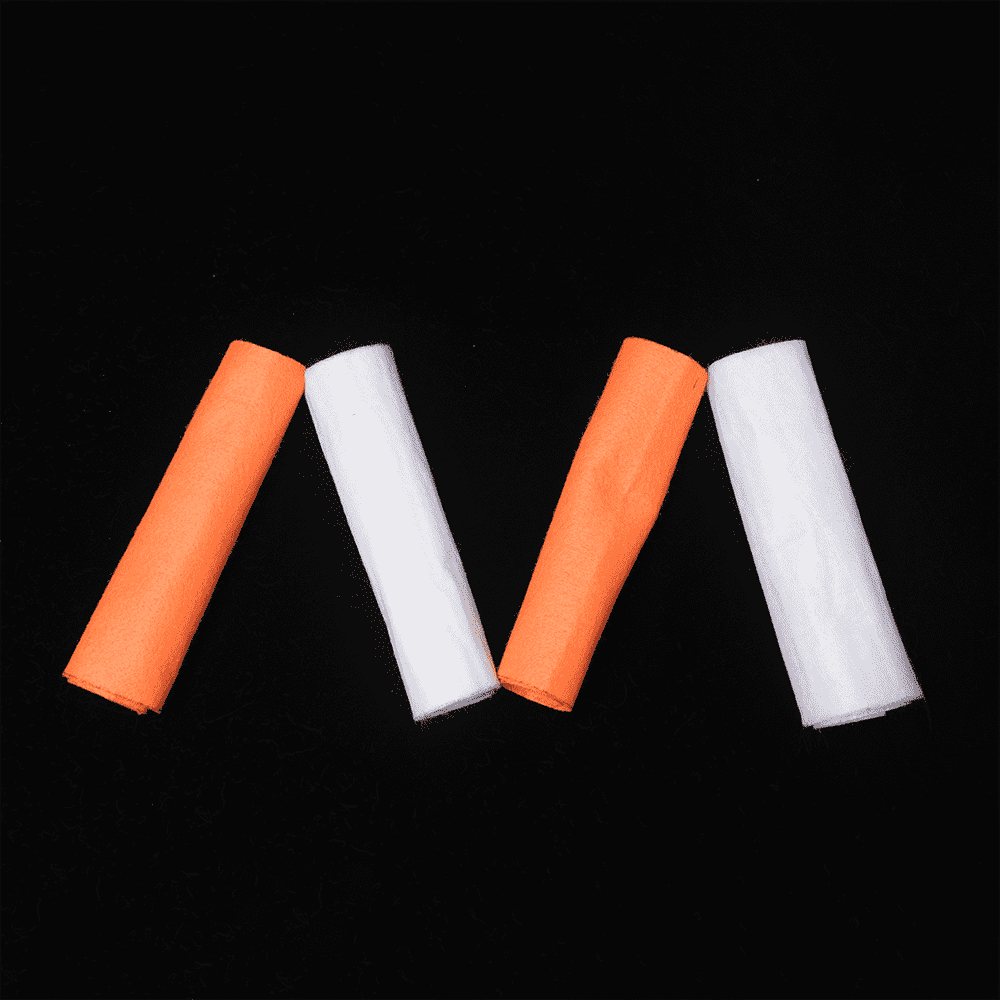

Packing of Top Quality Nonwoven Polypropylene Geotextile Price

You can freely choose PE film or PP woven bag for outer packaging, and there are paper tubes of different sizes inside the product for you to choose freely.

Staple Fiber Needled Non-woven Geotextile Technical Specifications ( GB/T17638-1998) | |||||||||||||

No. | Item | Specifications | Note | ||||||||||

100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 800 | |||

1 | Unit area mass deviation | -8 | -8 | -8 | -8 | -7 | -7 | -7 | -7 | -6 | 6 | -6 |

|

2 | Thickness mm≥ | 0.9 | 1.3 | 1.7 | 2.1 | 2.4 | 2.7 | 3.0 | 3.3 | 3.6 | 4.1 | 5.0 | |

3 | Width deviation | -0.5 | |||||||||||

4 | Breaking strength | 2.5 | 4.5 | 6.5 | 8.0 | 9.5 | 11 | 12.5 | 14.0 | 16.0 | 19.0 | 25.0 | Vertical and horizontal |

5 | Elongation at break % | 20-100 | |||||||||||

6 | CBR bursting strength | 0.3 | 0.6 | 0.8 | 1.2 | 1.4 | 1.8 | 2.1 | 2.4 | 2.7 | 3.2 | 4.0 |

|

7 | Equivalent aperture | 0.07-0.2 |

| ||||||||||

8 | Vertical permeability coefficient | K*(10-1~10-3) | K=1.0-9.9 | ||||||||||

9 | Tear strength | 0.08 | 0.12 | 0.16 | 0.20 | 0.24 | 0.28 | 0.33 | 0.38 | 0.42 | 0.46 | 0.6 | Vertical and horizontal |