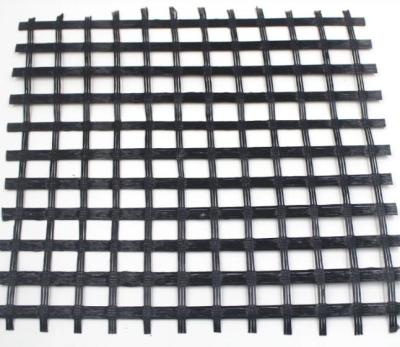

Application Cases of Spunbond Nonwoven Geotextiles

Application Cases of Spunbond Nonwoven Geotextiles

1. Road and Railway Construction

Project: Highway Reinforcement in Texas, USA

Challenge: Weak subgrade soil prone to erosion and differential settlement.

Solution: A 200 g/m² spunbond nonwoven geotextile was installed between the subgrade and aggregate base layer.

Results:

· Improved load distribution and reduced rutting.

· Prevented soil migration, extending the road’s lifespan by 30%.

· Reduced maintenance costs by 25% over 5 years.

Key Benefits: Separation, filtration, and reinforcement.

2. Landfill Liners and Caps

Project: Municipal Solid Waste Landfill, Germany

Challenge: Protecting groundwater from leachate contamination.

Solution: A 300 g/m² spunbond geotextile was used as a protective layer above the geomembrane liner and below the drainage layer.

Results:

· Enhanced puncture resistance for the geomembrane.

· Improved drainage efficiency while filtering particulates.

· Compliance with EU environmental regulations.

Key Benefits: Protection, filtration, and durability in harsh chemical environments.

3. Coastal Erosion Control

Project: Shoreline Stabilization, Netherlands

Challenge: Wave action eroding sandy coastal areas.

Solution: Spunbond geotextile tubes (500 g/m²) filled with local sand were deployed as breakwaters.

Results:

· Reduced wave energy by 40%, preserving the coastline.

· Vegetation regrowth observed within 12 months.

· Cost-effective compared to concrete structures.

Key Benefits: Permeability, UV resistance, and adaptability to dynamic environments.

4. Drainage Systems

Project: Urban Stormwater Management, Singapore

Challenge: Clogging of subsurface drainage pipes due to fine soil particles.

Solution: Spunbond geotextile (150 g/m²) wrapped around perforated drainage pipes.

Results:

· Sustained hydraulic conductivity over 8 years.

· Reduced sedimentation in pipes by 90%.

· Minimal maintenance required.

Key Benefits: Long-term filtration and anti-clogging performance.

5. Slope Stabilization

Project: Mountain Highway Slope, China

Challenge: Landslide risks due to heavy rainfall.

Solution: Layered spunbond geotextile (250 g/m²) combined with vegetation (grass planting).

Results:

· Slope stability achieved within 6 months.

· Erosion reduced by 70%.

· Aesthetic integration with the natural landscape.

Key Benefits: Biodegradability (optional), tensile strength, and erosion control.

Conclusion

Spunbond nonwoven geotextiles demonstrate versatility across infrastructure, environmental, and geotechnical projects. Their key advantages include:

· High tensile strength and elongation.

· Excellent permeability and filtration properties.

· Resistance to biological degradation and chemicals.

· Cost-effectiveness and ease of installation.

For customized solutions, engineers should select geotextile specifications (weight, thickness, permeability) based on site-specific load and hydraulic conditions.