Impervious isolation Composite Geotextile

Impervious isolation Composite Geotextile-PET geotextile is used as the substrate, and polyethylene, polyvinyl chloride and exceptional elements are used asthe membrane. The composite geotextile of the non-woven fabric, has one material with one membrane,two fabric with one membrane, two menbrane with one fabric ect,Tensile, tear resistance, pinnacle breaking and different bodily and mechanical overall performance symptoms are high, the product has excessive strength, excellent extension performance, giant deformation modulus, acid and alkali resistance, corrosion resistance, getting older resistance, properly anti-seepage overall performance and so on

Material: PET

Color: White

Film thickness: 0.1-1.0mm

Specification: 100g-800g

Length: 50-100m

Certificate: CE/ISO9001

Scope of application:

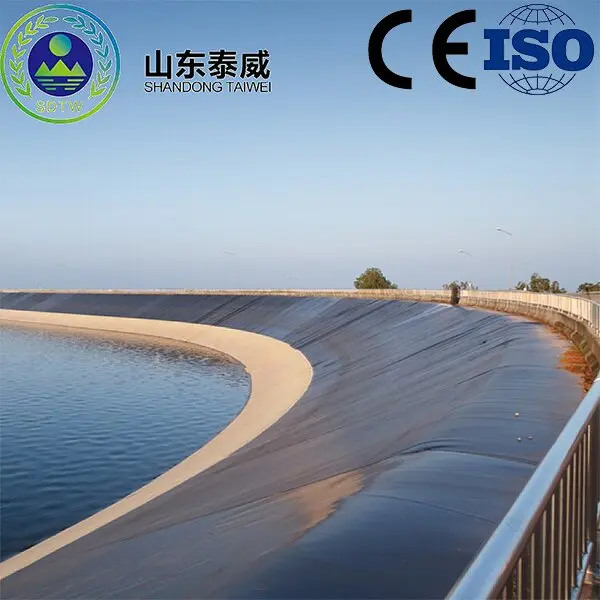

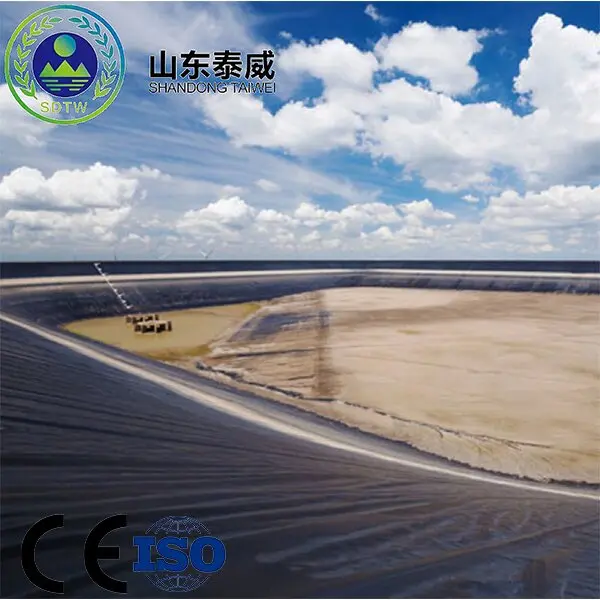

Impervious isolation Composite Geotextile,The selection of polymer materials and the production process added anti-aging agent, so it can be used in unconventional temperature environment. It is often used for anti-seepage treatment of dykes, drainage ditches, and anti-fouling treatment of waste yards. Function: seepage prevention, isolation use: earth dam, rockfill dam, masonry dam and spread pressure concrete dam; Horizontal anti-seepage covering in front of embankment and dam, vertical anti-seepage layer of foundation; Tailings dam, sewage storage dam body and reservoir area; Construction cofferdam; The extensive application of the composite geomembranes of channels and liquid storage ponds also plays a protective role in the ecological environment.

Good physical and mechanical properties

Impervious isolation Composite GeotextileGeotextile as the protective layer of geomembrane, so that the protective impervious layer is not damaged. In order to reduce UV exposure and increase anti-aging performance, it is best to use embedding method.

Construction suggestion

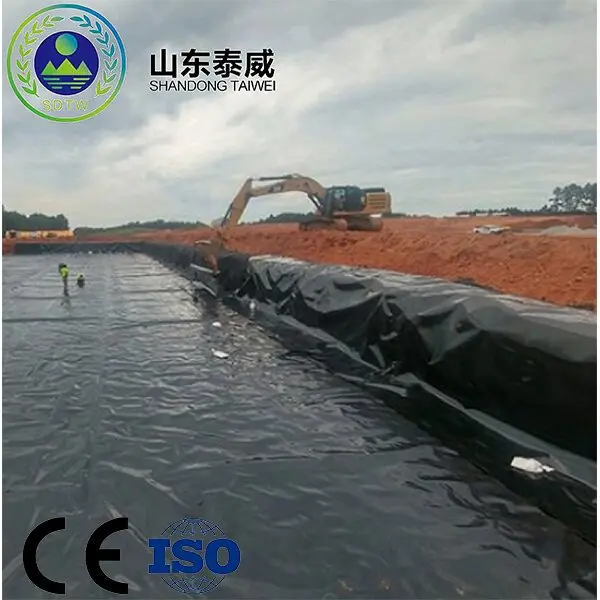

First of all, use small diameter sand or clay to level the base surface, and then lay geomembrane. Geomembrane do not be too tight, buried in the soil at both ends of the part is corrugated, and finally in the spread of geomembrane with fine sand or clay spread a layer of about 10cm over the layer. Build 20-30cm block stone (or concrete precast block) for anti-impact protection layer

Product implementation standards:

| Composite Geotextile Technical Specification | ||||||||||

| Item | Index | |||||||||

| 1 | Nominal breaking strength / ( kN / m ) | 5 | 7.5 | 10 | 12 | 14 | 16 | 18 | 20 | |

| 2 | Longitudinal and transverse rupture strength /( kN / m )≥ | 5.0 | 7.5 | 10 | 12 | 14 | 16 | 18 | 20 | |

| 3 | Vertical and horizontal standard strength corresponding to elongation /% | 30-100 | ||||||||

| 4 | CBR bursting strength /kN ≥ | 1.1 | 1.5 | 1.9 | 2.2 | 2.5 | 2.8 | 3.0 | 3.2 | |

| 5 | Vertical and horizontal tear strength / kN ≥ | 0.15 | 0.25 | 0.32 | 0.40 | 0.48 | 0.56 | 0.62 | 0.70 | |

| 8 | Vertical Permeability Index / ( cm / s) | According customer needs | ||||||||

| 9 | Width deviation /% | -1.0 | ||||||||

| Item | Membrane thickness/mm | |||||||||

| 0.2 | 0.3 | 0.4 | 0.5 | 0.6 | 0.7 | 0.8 | 1.0 | |||

| Hydrostatic pressure resistance / MPa | 1 fabric with 1 membrane | 0.4 | 0.5 | 0.6 | 0.8 | 1.0 | 1.2 | 1.4 | 1.6 | |

| 2 fabric with 1 membrane | 0.5 | 0.6 | 0.8 | 1.0 | 1.2 | 1.4 | 1.6 | 1.8 | ||

Packing of PET Composite Geotextile

You can freely pick out PE movie or PP woven bag for outer packaging, and there are paper tubes of exceptional sizes interior the product for you to pick freely.

Q: Can you inform me your predominant customers?

A: That is our customer's privacy, we have to defend their information.

At the identical time, please relaxation certain that your records is additionally protected here.

Geomembrane use

1. Before laying the geomembrane, the corresponding acceptance certificates of the civil engineering need to be obtained.

2. Before reducing the geomembrane, you must precisely measure its applicable size, and then reduce it in accordance to the authentic size. Generally, it is now not appropriate to reduce in accordance to the dimension proven in the figure. It have to be numbered one through one and recorded in element on the exceptional form.

3. When laying the geomembrane, the welding seam need to be minimized, and the uncooked substances ought to be saved as a lot as viable underneath the premise of making sure the quality. At the identical time, it is convenient to make certain the quality.

4. The overlapping width of the joint between the membrane and the membrane is typically now not much less than 10cm, and the route of the welding seam is generally organized parallel to the most slope, that is, organized alongside the slope direction.

5. Usually in corners and deformed areas, the size of the joint must be shortened as a whole lot as possible. Except for specific requirements, on slopes with a slope increased than 1:6, inside 1.5 meters from the pinnacle slope or the stress awareness area, strive now not to set up welds.

6. During the laying of the geomembrane, synthetic wrinkles have to be avoided. When the temperature is low, it ought to be stretched as a ways as viable and paved flat.

7. After the laying of the geomembrane is completed, taking walks and shifting equipment on the floor of the geomembrane must be minimized. Anything that can purpose damage to the anti-seepage membrane have to no longer be positioned or carried on the membrane to keep away from harm to the membrane. purpose unintended injury.

| Composite Geomembrane Technical Specification | ||||||||||

| Item | Index | |||||||||

| 1 | Nominal breaking strength / ( kN / m ) | 5 | 7.5 | 10 | 12 | 14 | 16 | 18 | 20 | |

| 2 | Longitudinal and transverse rupture strength /( kN / m )≥ | 5.0 | 7.5 | 10 | 12 | 14 | 16 | 18 | 20 | |

| 3 | Vertical and horizontal standard strength corresponding to elongation /% | 30-100 | ||||||||

| 4 | CBR bursting strength /kN ≥ | 1.1 | 1.5 | 1.9 | 2.2 | 2.5 | 2.8 | 3.0 | 3.2 | |

| 5 | Vertical and horizontal tear strength / kN ≥ | 0.15 | 0.25 | 0.32 | 0.40 | 0.48 | 0.56 | 0.62 | 0.70 | |

| 8 | Vertical Permeability Index / ( cm / s) | According customer needs | ||||||||

| 9 | Width deviation /% | -1.0 | ||||||||

| Item | Membrane thickness/mm | |||||||||

| 0.2 | 0.3 | 0.4 | 0.5 | 0.6 | 0.7 | 0.8 | 1.0 | |||

| Hydrostatic pressure resistance / MPa | 1 fabric with 1 membrane | 0.4 | 0.5 | 0.6 | 0.8 | 1.0 | 1.2 | 1.4 | 1.6 | |

| 2 fabric with 1 membrane | 0.5 | 0.6 | 0.8 | 1.0 | 1.2 | 1.4 | 1.6 | 1.8 | ||

| Composite Geomembrane Technical Specification | ||||||||||

| Item | Index | |||||||||

| 1 | Nominal breaking strength / ( kN / m ) | 5 | 7.5 | 10 | 12 | 14 | 16 | 18 | 20 | |

| 2 | Longitudinal and transverse rupture strength /( kN / m )≥ | 5.0 | 7.5 | 10 | 12 | 14 | 16 | 18 | 20 | |

| 3 | Vertical and horizontal standard strength corresponding to elongation /% | 30-100 | ||||||||

| 4 | CBR bursting strength /kN ≥ | 1.1 | 1.5 | 1.9 | 2.2 | 2.5 | 2.8 | 3.0 | 3.2 | |

| 5 | Vertical and horizontal tear strength / kN ≥ | 0.15 | 0.25 | 0.32 | 0.40 | 0.48 | 0.56 | 0.62 | 0.70 | |

| 8 | Vertical Permeability Index / ( cm / s) | According customer needs | ||||||||

| 9 | Width deviation /% | -1.0 | ||||||||

| Item | Membrane thickness/mm | |||||||||

| 0.2 | 0.3 | 0.4 | 0.5 | 0.6 | 0.7 | 0.8 | 1.0 | |||

| Hydrostatic pressure resistance / MPa | 1 fabric with 1 membrane | 0.4 | 0.5 | 0.6 | 0.8 | 1.0 | 1.2 | 1.4 | 1.6 | |

| 2 fabric with 1 membrane | 0.5 | 0.6 | 0.8 | 1.0 | 1.2 | 1.4 | 1.6 | 1.8 | ||