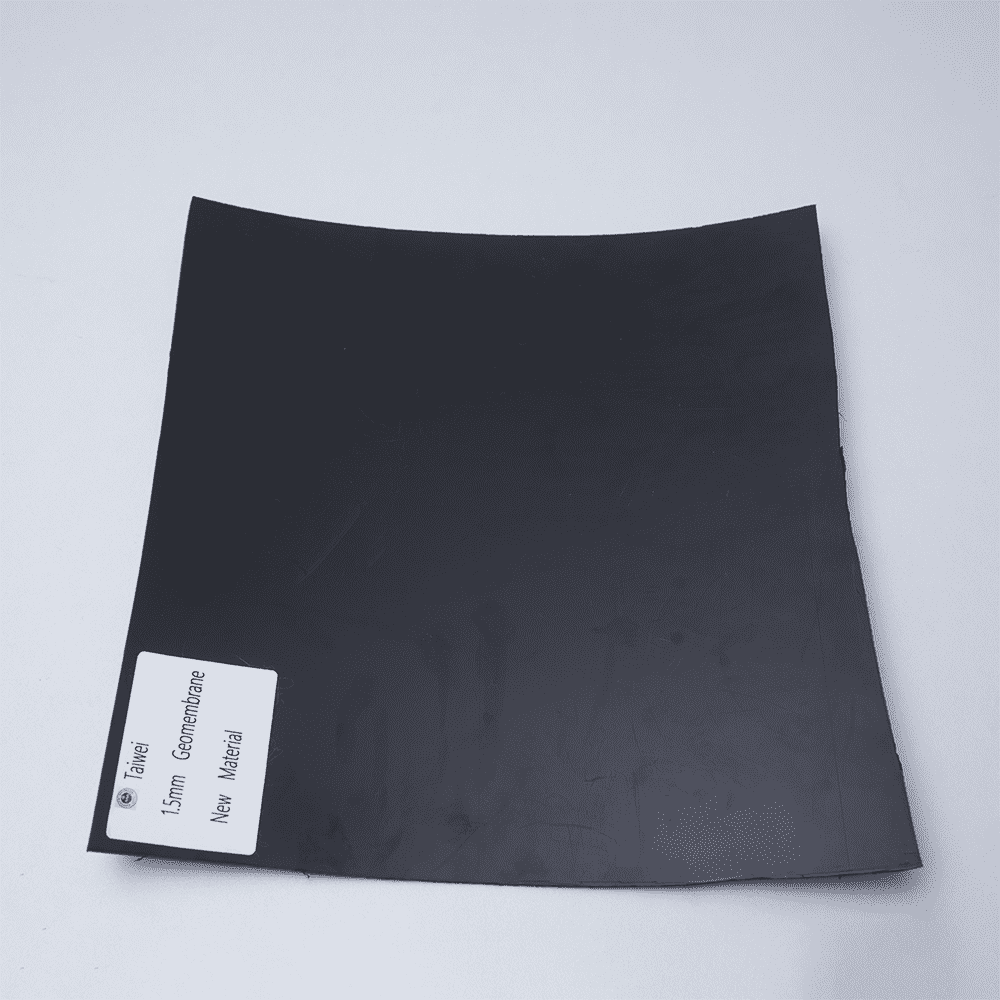

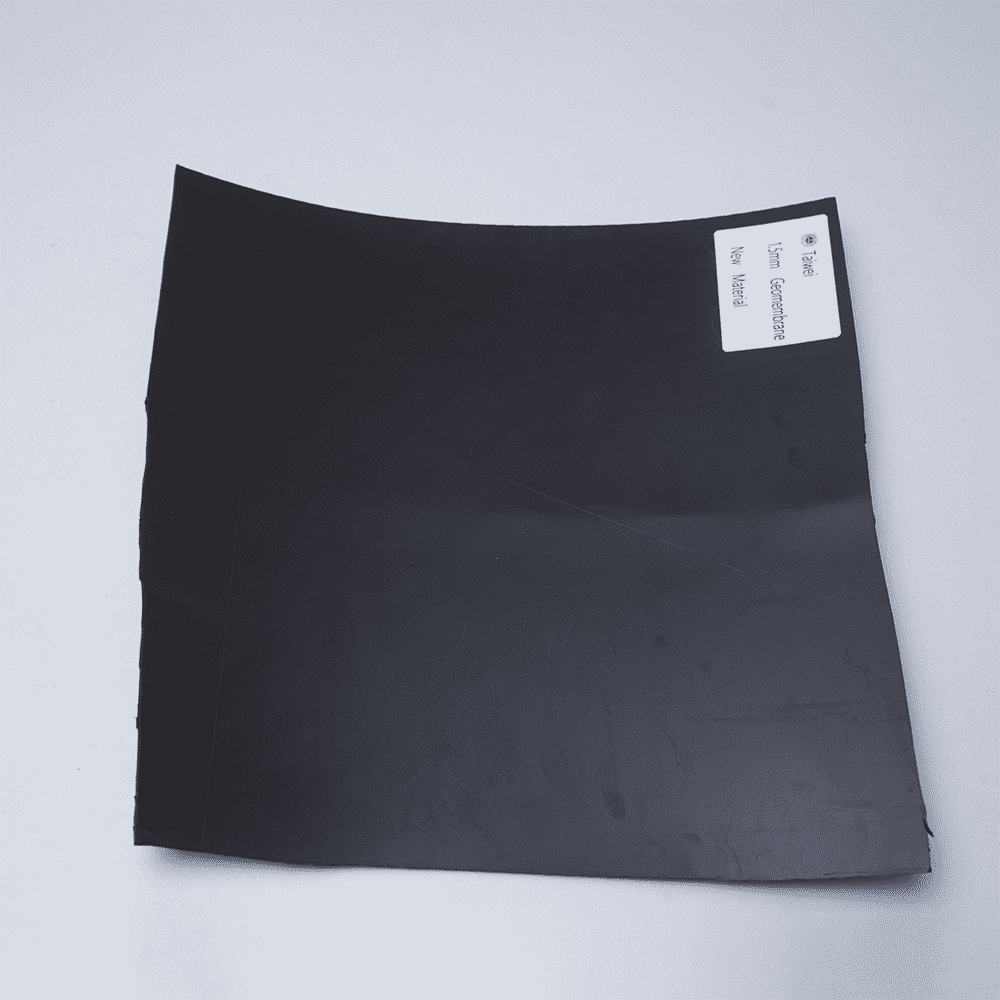

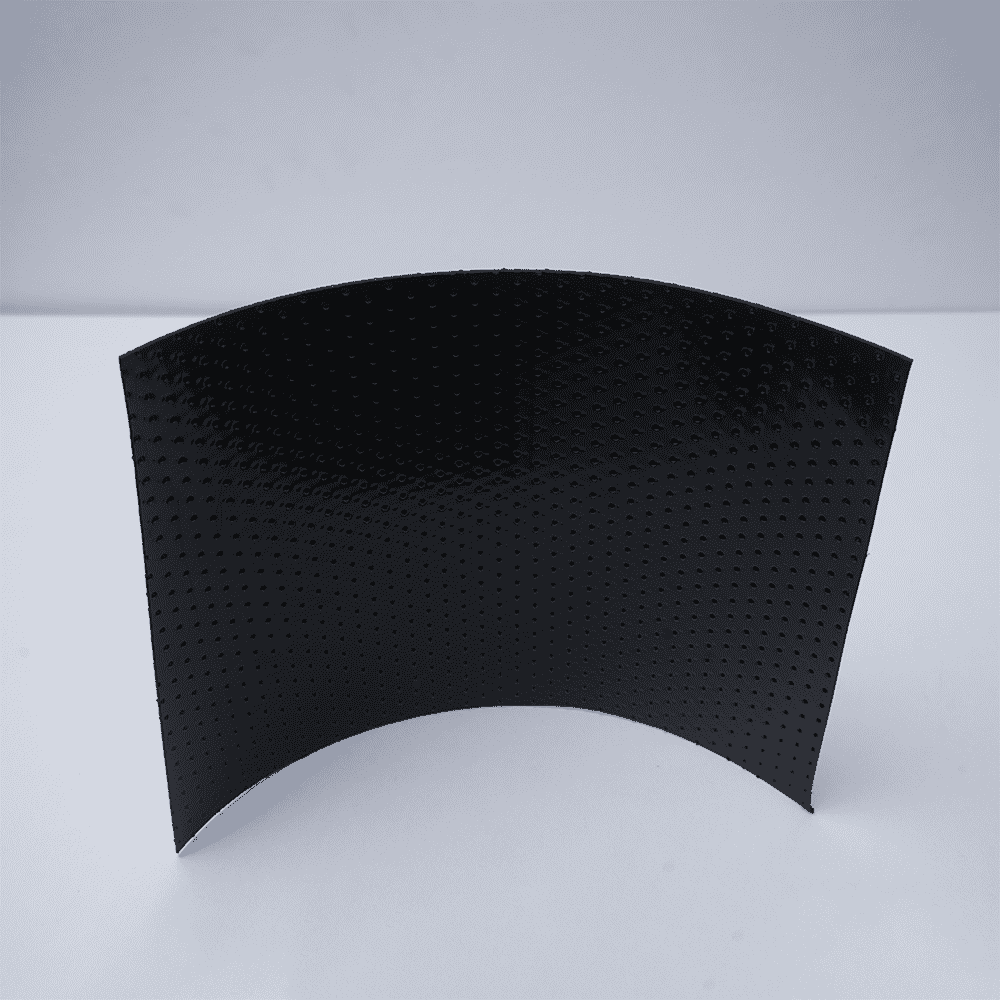

Anti-corrosion geomembrane for landfills

Product specifications:

Materials: Mainly divided into: low-density polyethylene (LDPE) geomembrane, high-density polyethylene (HDPE) geomembrane, and EVA geomembrane.

Thickness:0.3-3.3mm

Wide width: 1-8 meters

If there are special requirements, such as packaging requirements (width, length, thickness), please inform customer service personnel

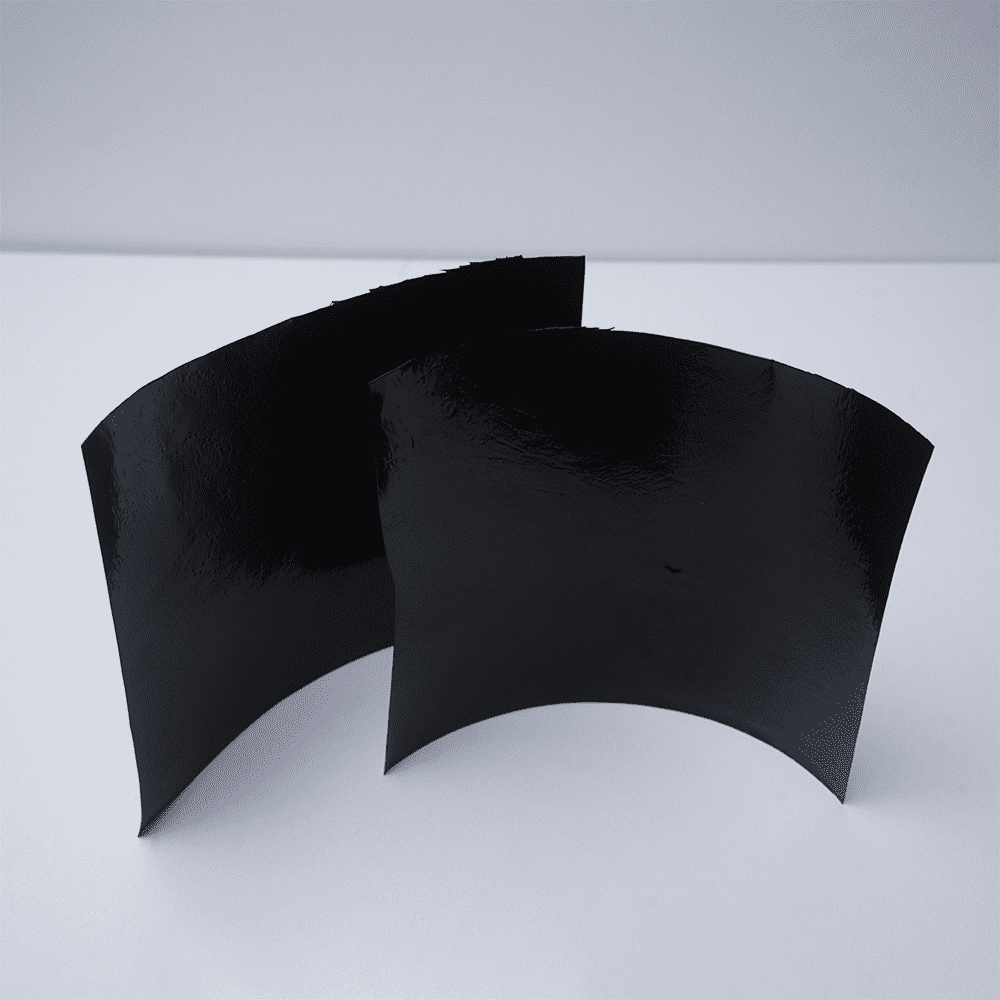

Pond anti-seepage HDPE geomembrane

HDPE geomembrane is a waterproof material made of polyethylene through blow molding or rock pressing. It has the functions of preventing leakage, puncture, corrosion, and isolation.

HDPE geomembrane is available in different thicknesses, ranging from 0.5mm to 3.0mm, depending on the specific needs of the project. The material can be fabricated into large panels or customized to fit specific dimensions, offering flexibility in installation.

Product characteristics:

1. It has strong flexibility and will bring better scalability in actual use. Only by grasping the laying site of the geomembrane and carrying out reasonable base layer treatment can flexibility bring better extension effects, and the technical quality in this area will be better. Only by strictly grasping the key technical points and details in this area will we know that anti-seepage construction is also very professional.

2. The ability to adapt to deformation is very high, and there will be no phenomenon of irreversible deformation. It has good corrosion resistance in strongly acidic or alkaline soil. In this way, the geomembrane has very good durability during anti-seepage construction. After all, the types of media will become more and more diverse, and they must be strictly controlled during the anti-seepage construction process to ensure that there will be no deformation, which means that they will not be damaged during use.

3. The geomembrane has good high temperature resistance and will not age in the open air in hot summers. Of course, in the cold winter, it has a good anti-freeze effect and will not become brittle. It can be seen that the characteristics have mastered many technologies in anti-seepage construction so that they can last longer in application.

The geomembrane uses a plastic film as the anti-seepage base material and is compounded with non-woven fabrics. The anti-seepage performance of the new material geomembrane mainly depends on the anti-seepage performance of the plastic film. Anti-seepage applications at home and abroad mainly include polyvinyl chloride (PVC), polyethylene (PE), EVA (ethylene/vinyl acetate copolymer), and tunnel applications also include ECB.

Application scope:

Anti-seepage in special environments such as landfills, sewage treatment plants, power plant tailings treatment, chemical plants, fertilizer plants, sugar factory sewage tailings treatment, non-ferrous metallurgy, sulfuric acid ponds, tailings treatment, subways, basements, tunnels, roof linings and other special environments (Exclusively used); Horizontal anti-seepage laying and vertical anti-seepage laying of reservoirs, canals, and dams; Seawater, fresh water, and breeding farms anti-seepage.

HDPE Geomembrane Technical Parameter (GRI GM13 ASTM Standard) | ||||||||

Spec Properties | Test | GMS0.5 | GMS0.75 | GMS1.0 | GMS1.25 | GMS1.5 | GMS2.0 | GMS2.5 |

Thickness | D5199 | 0.5mm | 0.75mm | 1.00mm | 1 .25mm | 1.50mm | 2.00mm | 2.50mm |

Density (≥ g/cc) | D1505 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 |

Tensile Properties | D6693 Type IV | 8 kN/m 14 kN/m 12% 700% | 11 kN/m | 15 kN/m | 18 kN/m | 22 kN/m 40 kN/m 12% 700% | 29kN/m 53 KN/m 12% 700% | 37kN/m 67kN/m 12% 700% |

Tear Resistance (≥) | D 1004 | 64N | 93N | 125 N | 156N | 187N | 249 N | 311 N |

Puncture Resistance(≥) | D 4833 | 160N | 240N | 320 N | 400 N | 480N | 640 N | 800 N |

Stress Crack Resistance (≥) | D 5397 | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr |

Carbon Black Content | D 1603 | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% |

Carbon Black Dispersion | D 5596 | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) |

Oxidative Induction Time(OIT)(≥) (a)Standard OIT ——or—— | D 3895 D 5885 | 100 min | 100 min | 100 min | 100 min | 100 min | 100 min | 100 min |

Packing of High Quality HDPE Geomembrane Pond Liner

Pond Liner geotextile membrane for water seepage prevention HDPE Geomembrane

Usage Scenarios of High Quality HDPE Geomembrane Pond Liner

HDPE Geomembrane Technical Parameter (GRI GM13 ASTM Standard) | ||||||||

Spec Properties | Test | GMS0.5 | GMS0.75 | GMS1.0 | GMS1.25 | GMS1.5 | GMS2.0 | GMS2.5 |

Thickness | D5199 | 0.5mm | 0.75mm | 1.00mm | 1 .25mm | 1.50mm | 2.00mm | 2.50mm |

Density (≥ g/cc) | D1505 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 |

Tensile Properties | D6693 Type IV | 8 kN/m 14 kN/m 12% 700% | 11 kN/m | 15 kN/m | 18 kN/m | 22 kN/m 40 kN/m 12% 700% | 29kN/m 53 KN/m 12% 700% | 37kN/m 67kN/m 12% 700% |

Tear Resistance (≥) | D 1004 | 64N | 93N | 125 N | 156N | 187N | 249 N | 311 N |

Puncture Resistance(≥) | D 4833 | 160N | 240N | 320 N | 400 N | 480N | 640 N | 800 N |

Stress Crack Resistance (≥) | D 5397 | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr |

Carbon Black Content | D 1603 | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% |

Carbon Black Dispersion | D 5596 | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) |

Oxidative Induction Time(OIT)(≥) (a)Standard OIT ——or—— | D 3895 D 5885 | 100 min | 100 min | 100 min | 100 min | 100 min | 100 min | 100 min |