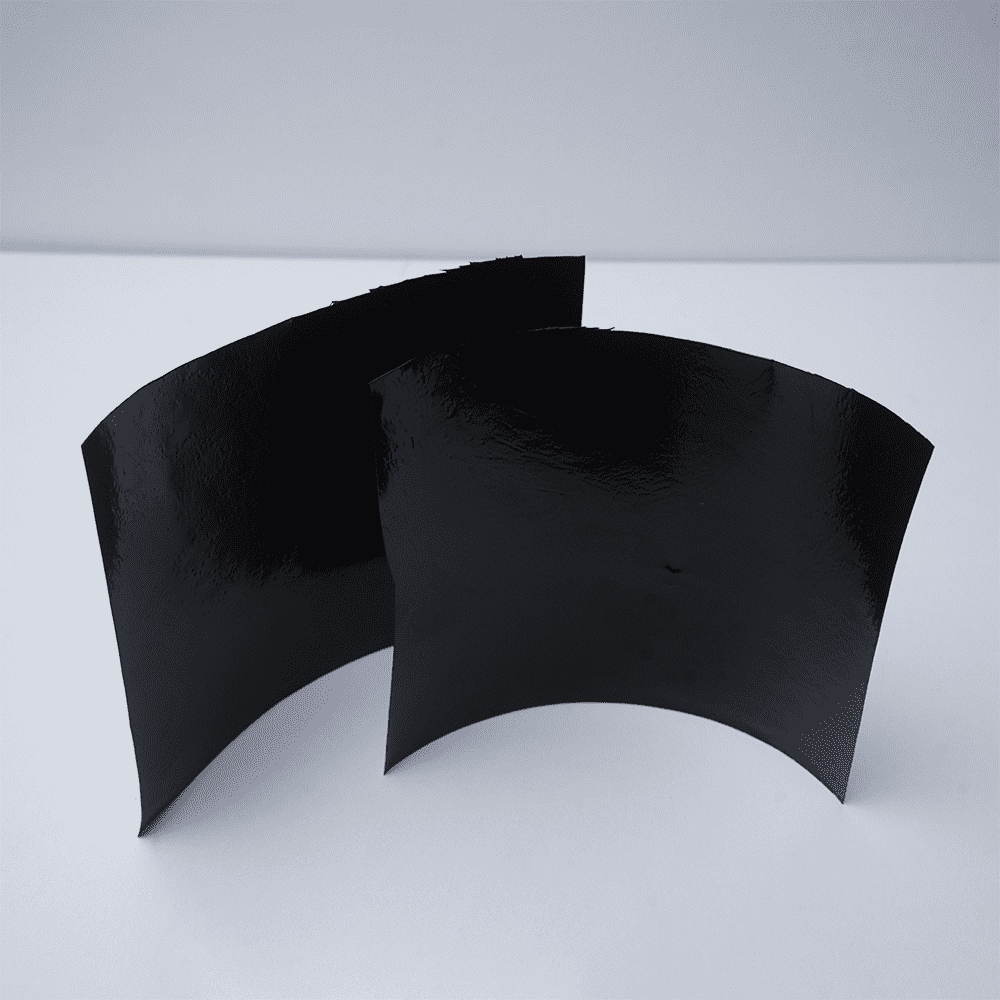

Dam anti-seepage geomembrane

Product specifications:

Materials: Mainly divided into: low-density polyethylene (LDPE) geomembrane, high-density polyethylene (HDPE) geomembrane, and EVA geomembrane.

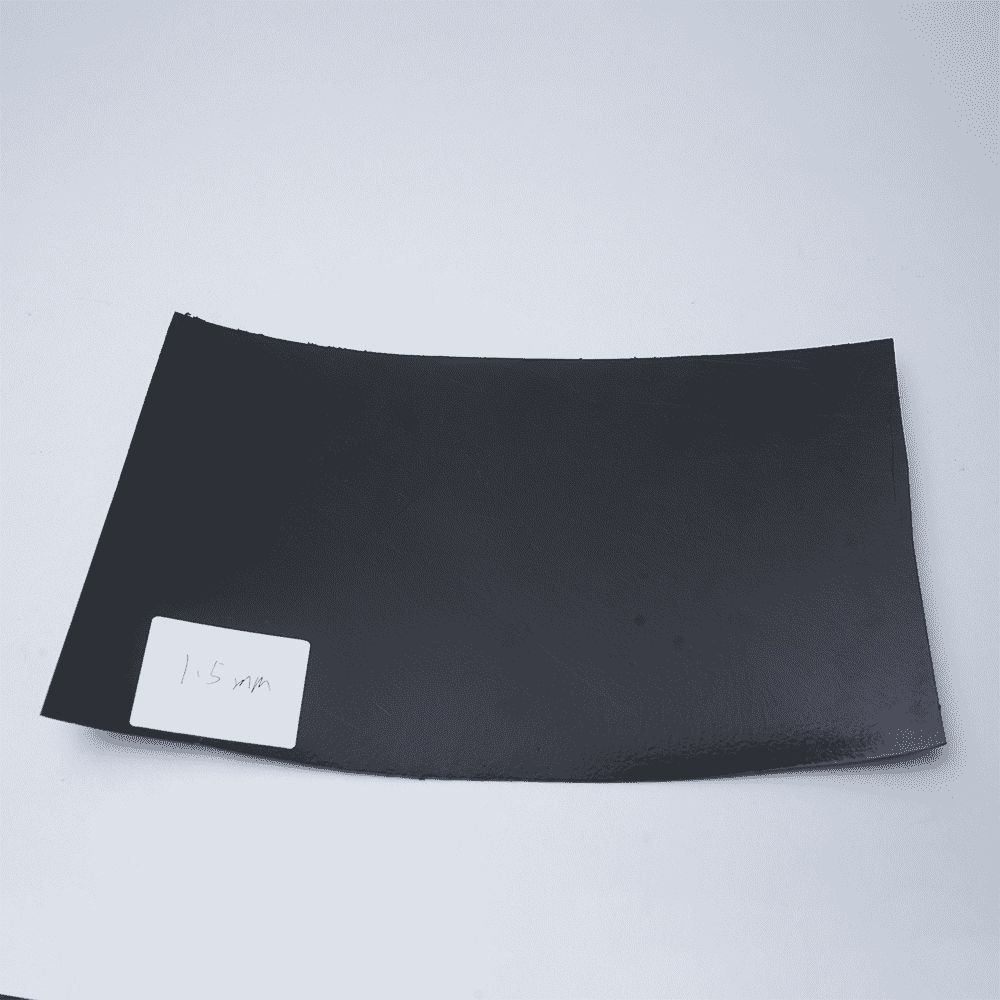

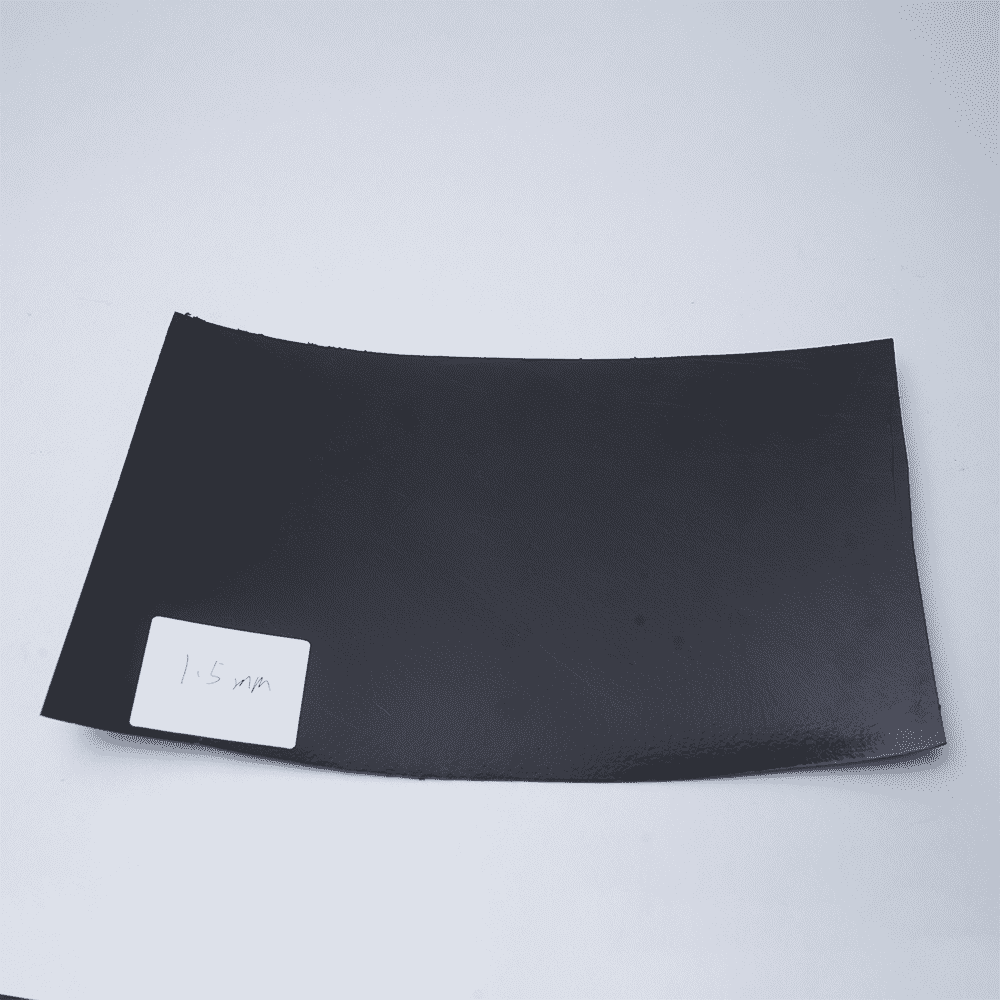

Thickness:0.3-3.3mm

Wide width: 1-8 meters

If there are special requirements, such as packaging requirements (width, length, thickness), please inform customer service personnel

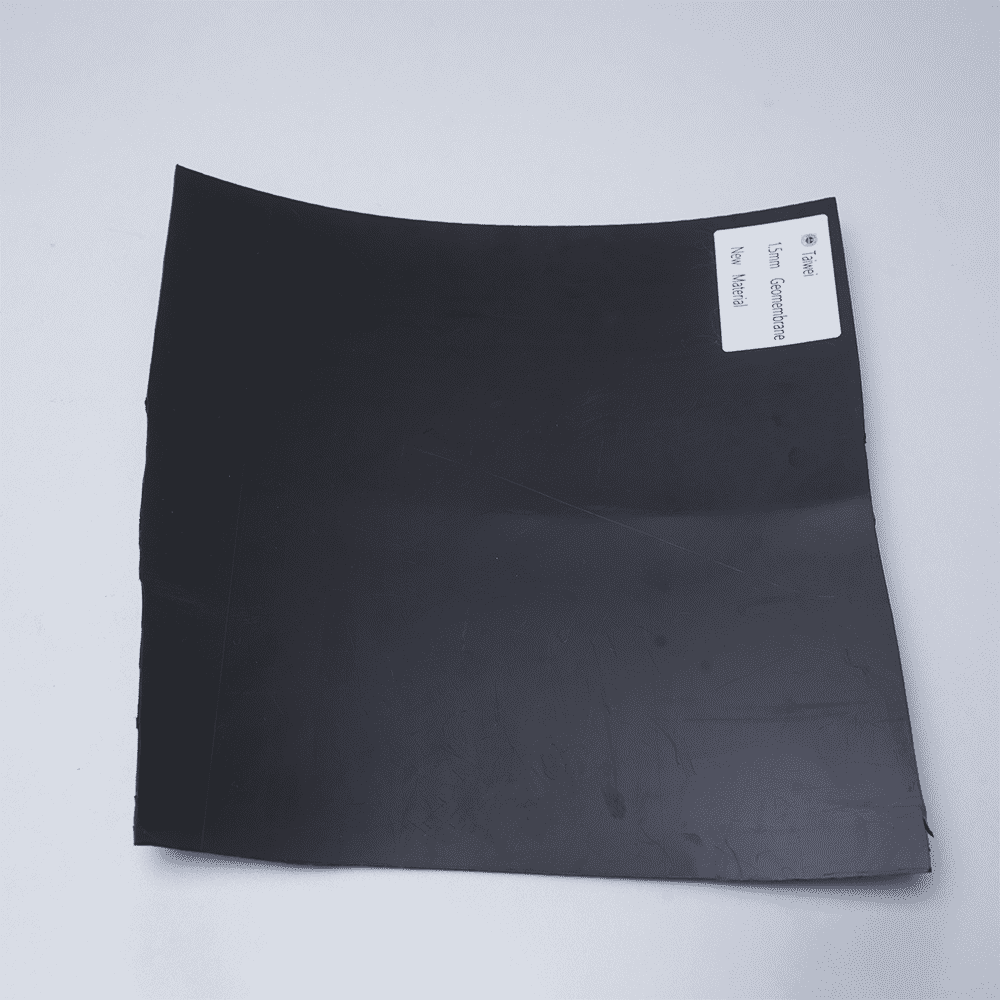

Pond anti-seepage HDPE geomembrane

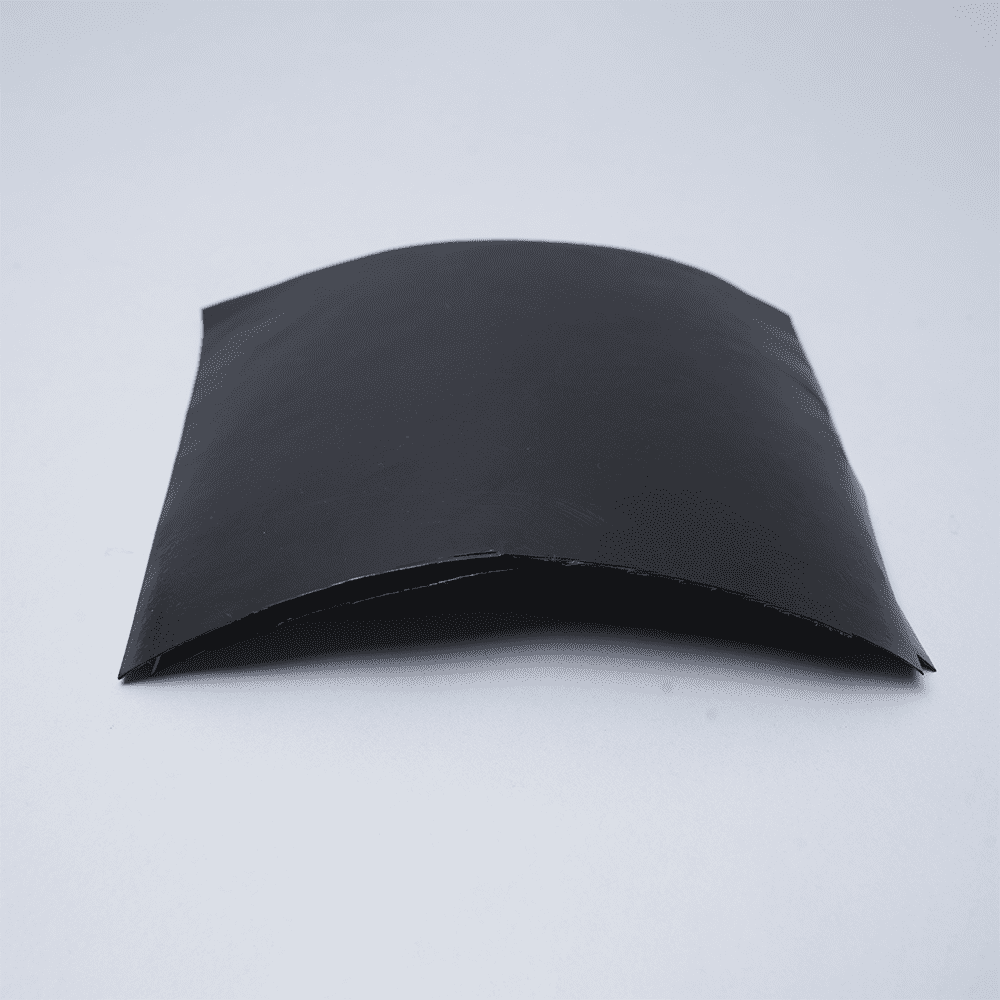

High-density polyethylene is a tough and durable material that offers excellent resistance to chemicals and ultraviolet (UV) radiation. This makes HDPE geomembrane resistant to corrosion, abrasion, and puncture, ensuring long-lasting performance in challenging environmental conditions.

The smooth surface of the HDPE geomembrane provides a low friction coefficient and superior hydraulic performance. It allows for efficient fluid flow and prevents leakage, thereby reducing the risk of environmental contamination. The geomembrane is also impermeable, preventing the migration of gases and liquids, which is crucial in containment applications.

HDPE geomembrane is available in different thicknesses, ranging from 0.5mm to 3.0mm, depending on the specific needs of the project. The material can be fabricated into large panels or customized to fit specific dimensions, offering flexibility in installation.

Product characteristics:

Excellent chemical resistance: HDPE geomembrane offers superior resistance to a wide range of chemicals, including acids, alkalis, and organic solvents.

UV resistance: The HDPE material contains stabilizers that provide resistance to UV radiation, ensuring long-term performance in exposed conditions.

High tensile strength and tear resistance: HDPE geomembrane has high tensile strength and tear resistance, making it suitable for applications that require robust puncture resistance.

Environmental protection: By preventing leakage and migration of pollutants, HDPE geomembrane plays a crucial role in protecting the environment and ensuring the safety of containment systems.

Easy installation: HDPE geomembrane can be fabricated into large panels or customized to specific dimensions, making it easy to install and fit various project requirements.

Application scope:

HDPE Geomembrane is a high-density polyethylene (HDPE) liner designed for various containment applications. It is widely used in environmental protection projects, such as landfill liners, waste water treatment plants, reservoirs, mining, agriculture, and pond-lining applications.

HDPE Geomembrane Technical Parameter (GRI GM13 ASTM Standard) | ||||||||

Spec Properties | Test | GMS0.5 | GMS0.75 | GMS1.0 | GMS1.25 | GMS1.5 | GMS2.0 | GMS2.5 |

Thickness | D5199 | 0.5mm | 0.75mm | 1.00mm | 1 .25mm | 1.50mm | 2.00mm | 2.50mm |

Density (≥ g/cc) | D1505 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 |

Tensile Properties | D6693 Type IV | 8 kN/m 14 kN/m 12% 700% | 11 kN/m | 15 kN/m | 18 kN/m | 22 kN/m 40 kN/m 12% 700% | 29kN/m 53 KN/m 12% 700% | 37kN/m 67kN/m 12% 700% |

Tear Resistance (≥) | D 1004 | 64N | 93N | 125 N | 156N | 187N | 249 N | 311 N |

Puncture Resistance(≥) | D 4833 | 160N | 240N | 320 N | 400 N | 480N | 640 N | 800 N |

Stress Crack Resistance (≥) | D 5397 | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr |

Carbon Black Content | D 1603 | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% |

Carbon Black Dispersion | D 5596 | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) |

Oxidative Induction Time(OIT)(≥) (a)Standard OIT ——or—— | D 3895 D 5885 | 100 min | 100 min | 100 min | 100 min | 100 min | 100 min | 100 min |

Packing of High Quality HDPE Geomembrane Pond Liner

Pond Liner geotextile membrane for water seepage prevention HDPE Geomembrane

Usage Scenarios of High Quality HDPE Geomembrane Pond Liner

HDPE Geomembrane Technical Parameter (GRI GM13 ASTM Standard) | ||||||||

Spec Properties | Test | GMS0.5 | GMS0.75 | GMS1.0 | GMS1.25 | GMS1.5 | GMS2.0 | GMS2.5 |

Thickness | D5199 | 0.5mm | 0.75mm | 1.00mm | 1 .25mm | 1.50mm | 2.00mm | 2.50mm |

Density (≥ g/cc) | D1505 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 |

Tensile Properties | D6693 Type IV | 8 kN/m 14 kN/m 12% 700% | 11 kN/m | 15 kN/m | 18 kN/m | 22 kN/m 40 kN/m 12% 700% | 29kN/m 53 KN/m 12% 700% | 37kN/m 67kN/m 12% 700% |

Tear Resistance (≥) | D 1004 | 64N | 93N | 125 N | 156N | 187N | 249 N | 311 N |

Puncture Resistance(≥) | D 4833 | 160N | 240N | 320 N | 400 N | 480N | 640 N | 800 N |

Stress Crack Resistance (≥) | D 5397 | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr |

Carbon Black Content | D 1603 | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% |

Carbon Black Dispersion | D 5596 | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) |

Oxidative Induction Time(OIT)(≥) (a)Standard OIT ——or—— | D 3895 D 5885 | 100 min | 100 min | 100 min | 100 min | 100 min | 100 min | 100 min |

Related Products

Submitted successfully

We will contact you as soon as possible

Submitted successfully

We will contact you as soon as possible