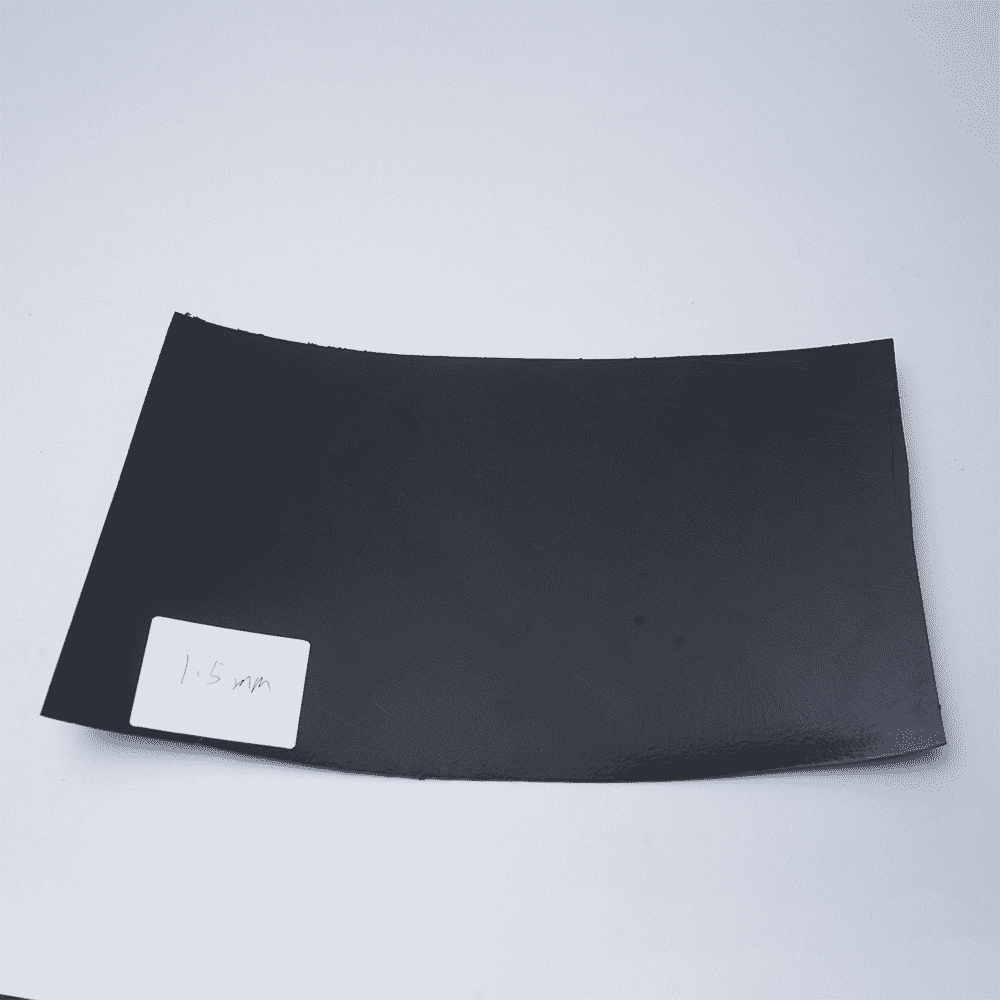

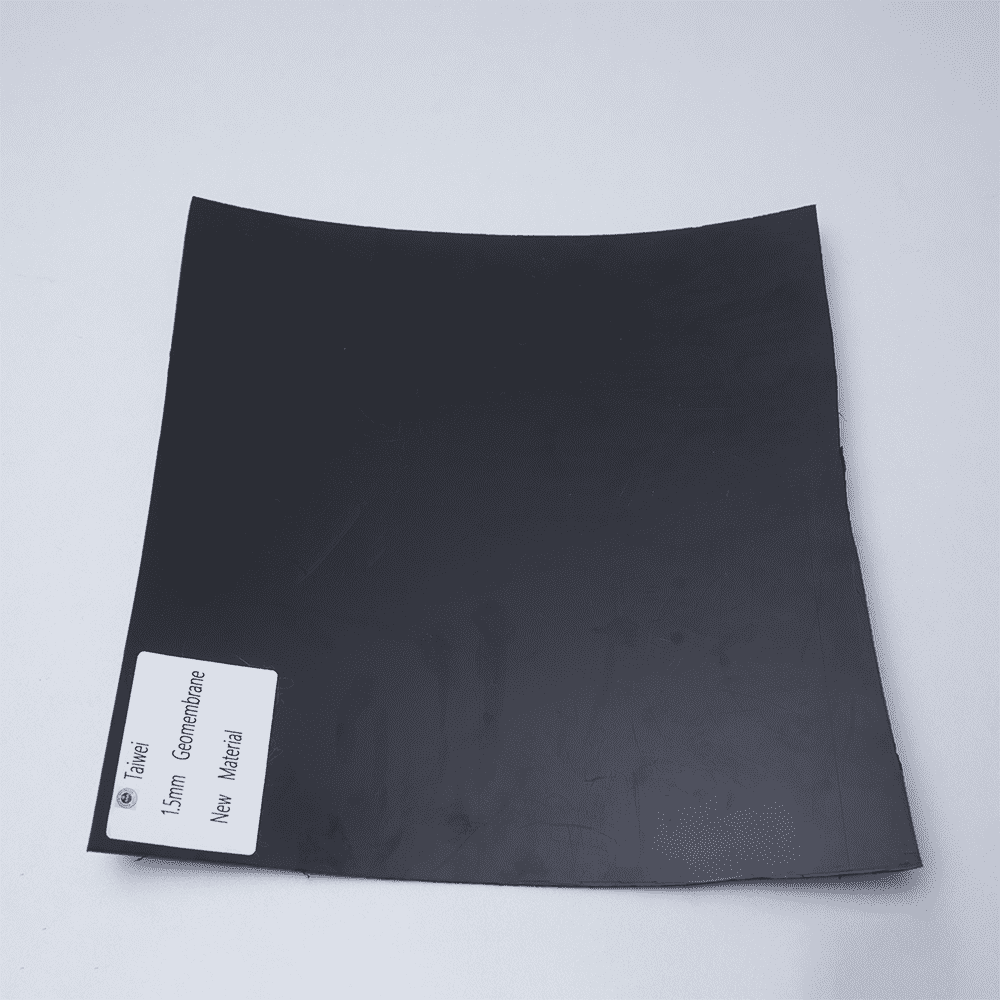

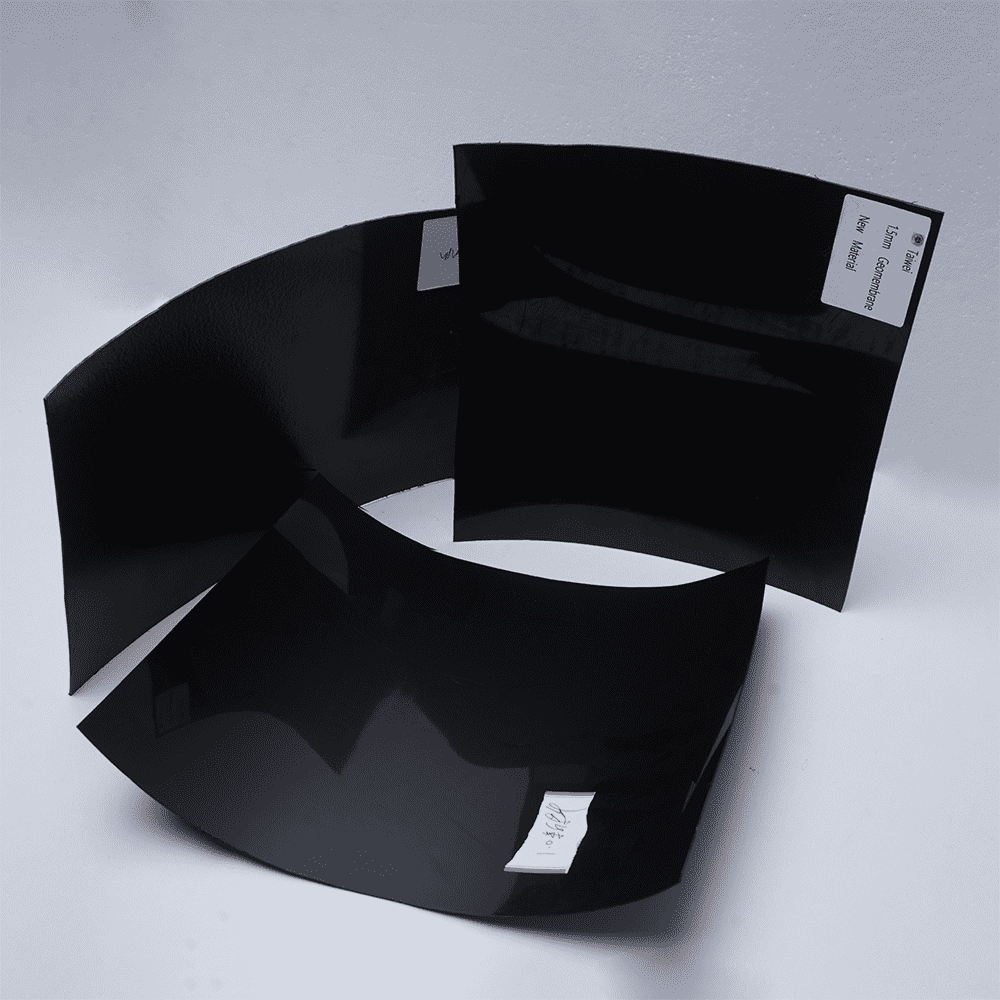

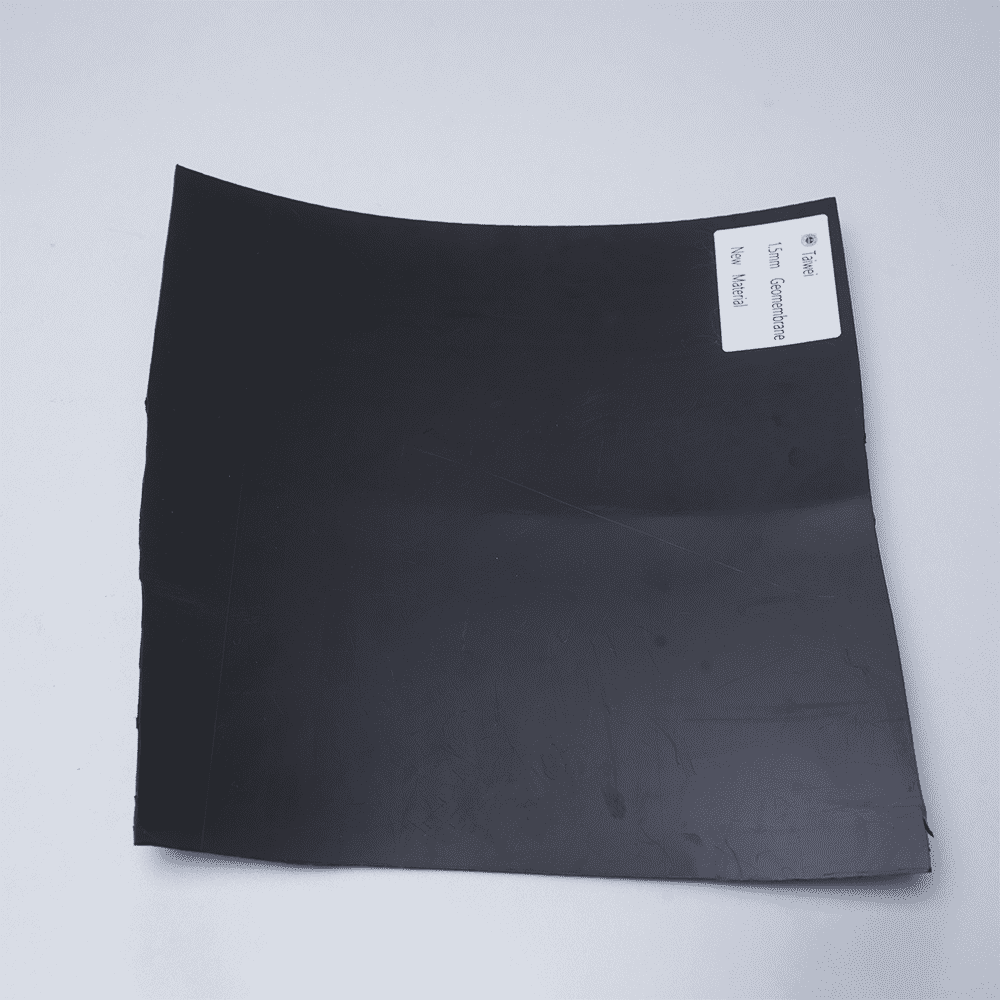

Pond anti-seepage HDPE geomembrane

Product specifications:

Materials: Mainly divided into: low-density polyethylene (LDPE) geomembrane, high-density polyethylene (HDPE) geomembrane, and EVA geomembrane.

Thickness:0.3-3.3mm

Wide width: 1-8 meters

If there are special requirements, such as packaging requirements (width, length, thickness), please inform customer service personnel

Pond anti-seepage HDPE geomembrane

HDPE composite HDPE film is also called high-density polyethylene film, HDPE geomembrane, and HDPE anti-seepage film. HDPE film is a plastic roll made of HDPE, which is a highly crystalline, non-polar thermoplastic resin. The appearance of original HDPE is milky white, and it is translucent to a certain extent in thin sections. PE has excellent resistance to most domestic and industrial chemicals.

Product characteristics:

1. HDPE geomembrane is a flexible waterproof material with a high anti-seepage coefficient (1×10-17 cm/s);

2. HDPE geomembrane has good heat resistance and cold resistance, and its operating environment temperature is high temperature 110℃ and low temperature -70℃;

3. HDPE geomembrane has good chemical stability and can resist corrosion from strong acids, alkalis and oils and is a good anti-corrosion material;

4. HDPE geomembrane has high tensile strength, making it capable of meeting the needs of high-standard engineering projects;

5. HDPE geomembrane has strong weather resistance and anti-aging properties, and can be used exposed for a long time while maintaining its original performance;

6. The overall performance of HDPE geomembrane. HDPE geomembrane has strong tensile strength and elongation at break, allowing HDPE geomembrane to be used in various harsh geological and climatic conditions. Strong adaptability to uneven geological settlement!

7. HDPE geomembrane uses high-quality virgin plastic and carbon black particles without any preservatives. HDPE has been used in my country to replace PVC as the raw material for food packaging bags and plastic wrap.

Application scope:

It is widely used in domestic waste landfill anti-seepage, solid waste landfill anti-seepage, sewage treatment plant anti-seepage, artificial lake anti-seepage, tailings treatment and other anti-seepage projects.

HDPE Geomembrane Technical Parameter (GRI GM13 ASTM Standard) | ||||||||

Spec Properties | Test | GMS0.5 | GMS0.75 | GMS1.0 | GMS1.25 | GMS1.5 | GMS2.0 | GMS2.5 |

Thickness | D5199 | 0.5mm | 0.75mm | 1.00mm | 1 .25mm | 1.50mm | 2.00mm | 2.50mm |

Density (≥ g/cc) | D1505 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 |

Tensile Properties | D6693 Type IV | 8 kN/m 14 kN/m 12% 700% | 11 kN/m | 15 kN/m | 18 kN/m | 22 kN/m 40 kN/m 12% 700% | 29kN/m 53 KN/m 12% 700% | 37kN/m 67kN/m 12% 700% |

Tear Resistance (≥) | D 1004 | 64N | 93N | 125 N | 156N | 187N | 249 N | 311 N |

Puncture Resistance(≥) | D 4833 | 160N | 240N | 320 N | 400 N | 480N | 640 N | 800 N |

Stress Crack Resistance (≥) | D 5397 | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr |

Carbon Black Content | D 1603 | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% |

Carbon Black Dispersion | D 5596 | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) |

Oxidative Induction Time(OIT)(≥) (a)Standard OIT ——or—— | D 3895 D 5885 | 100 min | 100 min | 100 min | 100 min | 100 min | 100 min | 100 min |

Packing of High Quality HDPE Geomembrane Pond Liner

Pond liner geotextile membrane for water seepage prevention HDPE Geomembrane

Usage Scenarios of High Quality HDPE Geomembrane Pond Liner

HDPE Geomembrane Technical Parameter (GRI GM13 ASTM Standard) | ||||||||

Spec Properties | Test | GMS0.5 | GMS0.75 | GMS1.0 | GMS1.25 | GMS1.5 | GMS2.0 | GMS2.5 |

Thickness | D5199 | 0.5mm | 0.75mm | 1.00mm | 1 .25mm | 1.50mm | 2.00mm | 2.50mm |

Density (≥ g/cc) | D1505 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 |

Tensile Properties | D6693 Type IV | 8 kN/m 14 kN/m 12% 700% | 11 kN/m | 15 kN/m | 18 kN/m | 22 kN/m 40 kN/m 12% 700% | 29kN/m 53 KN/m 12% 700% | 37kN/m 67kN/m 12% 700% |

Tear Resistance (≥) | D 1004 | 64N | 93N | 125 N | 156N | 187N | 249 N | 311 N |

Puncture Resistance(≥) | D 4833 | 160N | 240N | 320 N | 400 N | 480N | 640 N | 800 N |

Stress Crack Resistance (≥) | D 5397 | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr |

Carbon Black Content | D 1603 | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% |

Carbon Black Dispersion | D 5596 | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) |

Oxidative Induction Time(OIT)(≥) (a)Standard OIT ——or—— | D 3895 D 5885 | 100 min | 100 min | 100 min | 100 min | 100 min | 100 min | 100 min |

Related Products

Submitted successfully

We will contact you as soon as possible