Special anti-seepage HDPE geomembrane for reservoir fish farm

Product specifications;

Materials; Mainly divided into: low-density polyethylene (LDPE) geomembrane, high-density polyethylene (HDPE) geomembrane, and EVA geomembrane.

Thickness; 1.0-2.0mm

Wide width; 4-8 meters

If there are special requirements, such as packaging requirements (width, length, thickness), please inform customer service personnel

Special anti-seepage HDPE geomembrane for reservoir fish farm

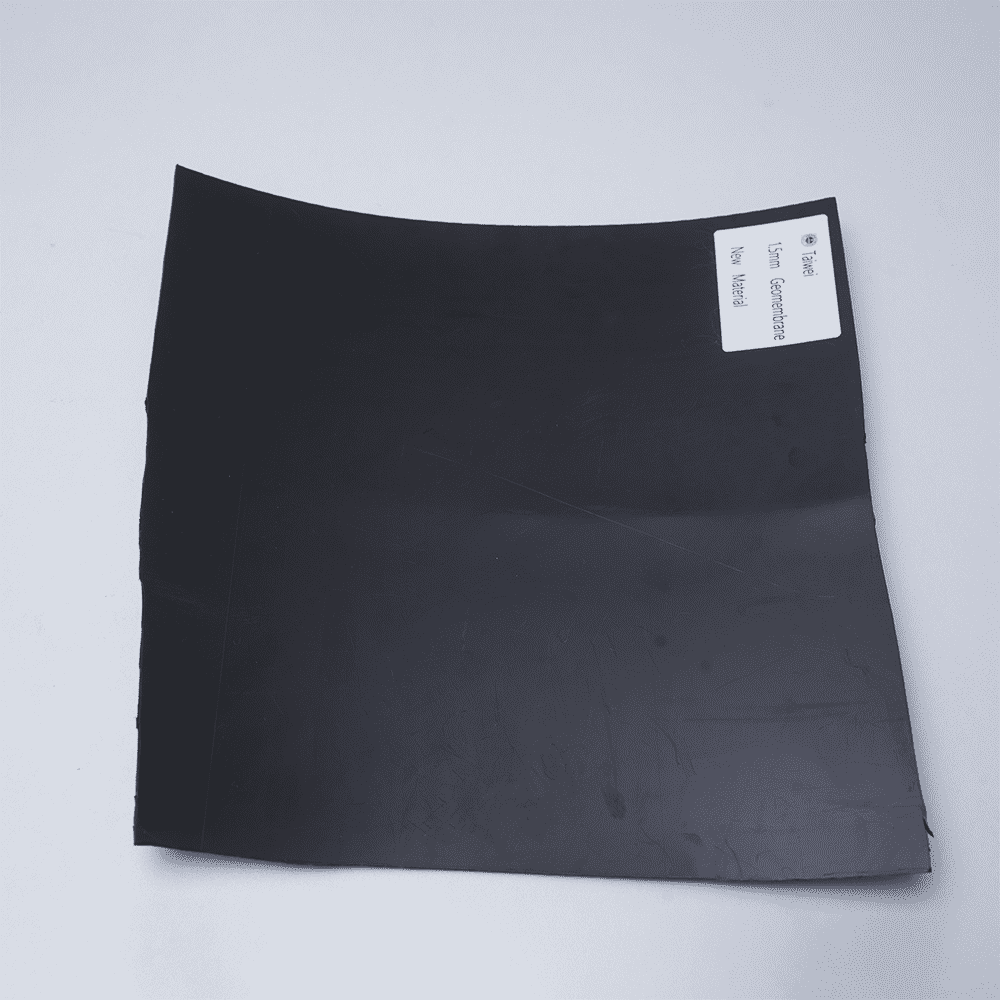

HDPE Geomembrane

The HDPE (High-Density Polyethylene) Geomembrane is a highly versatile and durable geosynthetic product used in a range of industries. It is designed to serve as a barrier, preventing fluid migration, seepage, or contamination in various applications.

The HDPE geomembrane is made from high-quality polyethylene resins through a state-of-the-art manufacturing process. It possesses excellent chemical resistance, UV stability, and high tensile strength, making it suitable for demanding environmental conditions.

Product characteristics;

Chemical Resistance: HDPE geomembranes offer exceptional resistance against a wide range of chemicals, including acids, alkalis, and oils. This makes them ideal for containment applications in chemical storage facilities, landfills, waste treatment plants, and mining projects.

Impermeability: With its superior impermeability, the HDPE geomembrane effectively prevents the passage of liquids, gases, and other contaminants. Its low permeability ensures maximum protection against ground and water pollution.

UV Stability: The geomembrane is manufactured with advanced UV stabilizers, providing excellent resistance to aging and prolonged exposure to sunlight. This ensures long-term performance and durability even under harsh climatic conditions.

High Tensile Strength: HDPE geomembranes possess high tensile strength, enabling them to withstand stress and strain during installation and long-term use. This attribute provides the stability required for geotechnical applications such as reservoirs, dams, canals, and embankments.

Flexibility and Durability: The flexibility of HDPE geomembranes makes them easy to handle and install, conforming to various surface irregularities. Additionally, they perform well in both high and low temperatures, making them suitable for diverse environmental conditions.

Application scope;

Environmental Protection: HDPE geomembranes are widely used in landfill liner systems, leachate collection ponds, and hazardous waste storage facilities to prevent leakage and contamination.

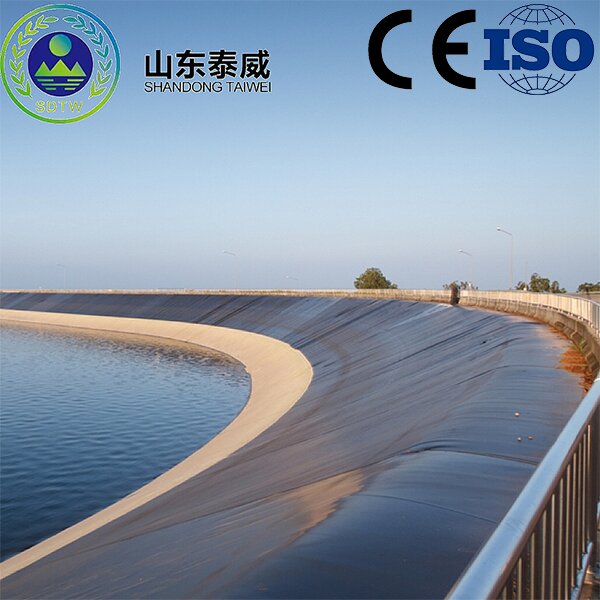

Water and Wastewater Management: HDPE geomembranes serve as effective liners for water reservoirs, ponds, lakes, canals, and wastewater treatment facilities, preventing water loss and contamination.

Mining and Oil & Gas: The high chemical resistance of HDPE geomembranes makes them ideal for controlling seepage and pollution in tailings ponds, heap leach pads, and process water containment.

Agriculture and Aquaculture: These geomembranes are utilized as pond liners, reservoir covers, and canal liners to prevent seepage, ensure water quality, and improve irrigation efficiency.

Civil Engineering: HDPE geomembranes are used in various civil engineering projects, including dam and canal construction, roadways, tunnels, and underground structures, for their stability and water-tightness.

HDPE Geomembrane Technical Parameter (GRI GM13 ASTM Standard) | ||||||||

Spec Properties | Test | GMS0.5 | GMS0.75 | GMS1.0 | GMS1.25 | GMS1.5 | GMS2.0 | GMS2.5 |

Thickness | D5199 | 0.5mm | 0.75mm | 1.00mm | 1 .25mm | 1.50mm | 2.00mm | 2.50mm |

Density (≥ g/cc) | D1505 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 |

Tensile Properties | D6693 Type IV | 8 kN/m 14 kN/m 12% 700% | 11 kN/m | 15 kN/m | 18 kN/m | 22 kN/m 40 kN/m 12% 700% | 29kN/m 53 KN/m 12% 700% | 37kN/m 67kN/m 12% 700% |

Tear Resistance (≥) | D 1004 | 64N | 93N | 125 N | 156N | 187N | 249 N | 311 N |

Puncture Resistance(≥) | D 4833 | 160N | 240N | 320 N | 400 N | 480N | 640 N | 800 N |

Stress Crack Resistance (≥) | D 5397 | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr |

Carbon Black Content | D 1603 | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% |

Carbon Black Dispersion | D 5596 | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) |

Oxidative Induction Time(OIT)(≥) (a)Standard OIT ——or—— | D 3895 D 5885 | 100 min | 100 min | 100 min | 100 min | 100 min | 100 min | 100 min |

Packing of High Quality HDPE Geomembrane Pond Liner

Pond liner geotextile membrane for water seepage prevention HDPE Geomembrane

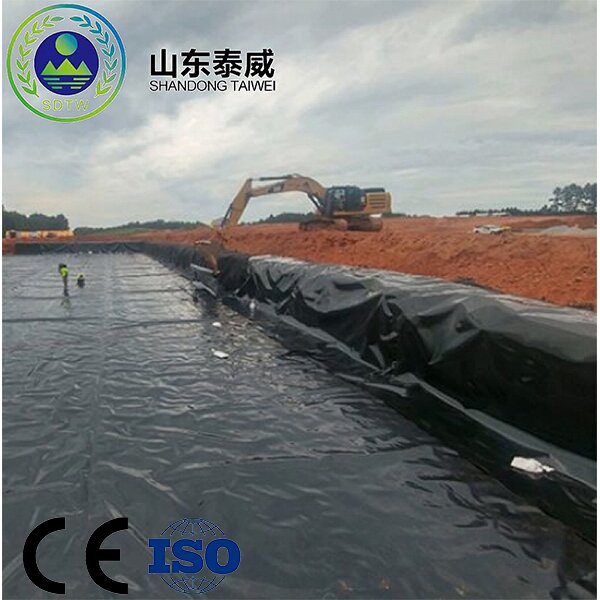

Usage Scenarios of High Quality HDPE Geomembrane Pond Liner

HDPE Geomembrane Technical Parameter (GRI GM13 ASTM Standard) | ||||||||

Spec Properties | Test | GMS0.5 | GMS0.75 | GMS1.0 | GMS1.25 | GMS1.5 | GMS2.0 | GMS2.5 |

Thickness | D5199 | 0.5mm | 0.75mm | 1.00mm | 1 .25mm | 1.50mm | 2.00mm | 2.50mm |

Density (≥ g/cc) | D1505 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 |

Tensile Properties | D6693 Type IV | 8 kN/m 14 kN/m 12% 700% | 11 kN/m | 15 kN/m | 18 kN/m | 22 kN/m 40 kN/m 12% 700% | 29kN/m 53 KN/m 12% 700% | 37kN/m 67kN/m 12% 700% |

Tear Resistance (≥) | D 1004 | 64N | 93N | 125 N | 156N | 187N | 249 N | 311 N |

Puncture Resistance(≥) | D 4833 | 160N | 240N | 320 N | 400 N | 480N | 640 N | 800 N |

Stress Crack Resistance (≥) | D 5397 | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr |

Carbon Black Content | D 1603 | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% |

Carbon Black Dispersion | D 5596 | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) |

Oxidative Induction Time(OIT)(≥) (a)Standard OIT ——or—— | D 3895 D 5885 | 100 min | 100 min | 100 min | 100 min | 100 min | 100 min | 100 min |