Special geomembrane for landfills and dams to prevent seepage and corrosion

Product specifications;

Materials; Mainly divided into: low-density polyethylene (LDPE) geomembrane, high-density polyethylene (HDPE) geomembrane, and EVA geomembrane.

Thickness; 0.3-3.0mm

Wide width; 1-8 meters

If there are special requirements, such as packaging requirements (width, length, thickness), please inform customer service personnel

Special geomembrane for landfills and dams to prevent seepage and corrosion

Product Introduction:

Our HDPE Geomembrane is a high-density polyethylene (HDPE) material specially designed for geotechnical engineering applications. Made from premium quality raw materials, our HDPE Geomembrane offers exceptional strength, durability, and long-lasting performance, making it an ideal solution for various containment and protection applications.

Product characteristics;

1.Superior Strength: Our HDPE Geomembrane exhibits high tensile strength and tear resistance, ensuring excellent structural integrity and providing long-term stability even under extreme conditions.

2.Chemical Resistance: The geomembrane is resistant to a wide range of chemicals, including acids, alkalis, and hydrocarbons, making it highly suitable for applications involving chemical containment.

3.UV Resistance: With excellent UV resistance, our HDPE Geomembrane provides long-term performance in harsh outdoor environments, maintaining its integrity and preventing degradation caused by sunlight exposure.

4.Impermeability: The geomembrane is impermeable to liquids and gases, ensuring effective containment of fluids and gases within various applications such as landfills, ponds, and reservoirs.

5.Cost-Effective: Our HDPE Geomembrane offers an economical solution for a wide range of applications, as it is durable, easy to install, and requires minimal maintenance over its lifetime.

Application scope;

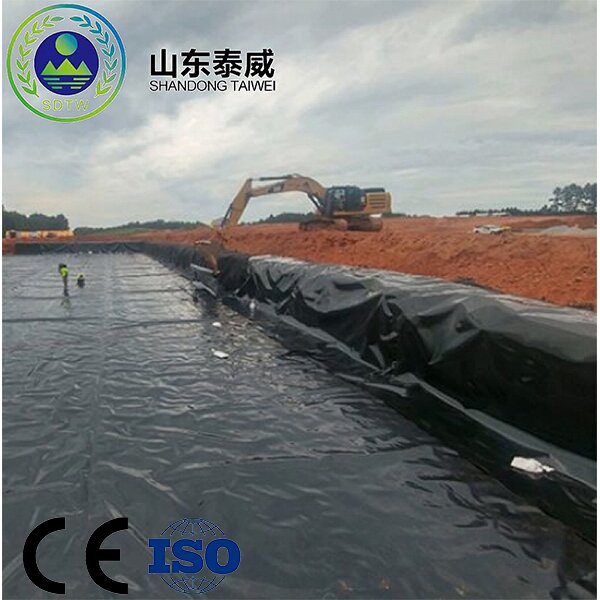

1.Landfill Liners and Caps: Our HDPE Geomembrane serves as an effective barrier, preventing the migration of contaminants from landfills into the surrounding environment.

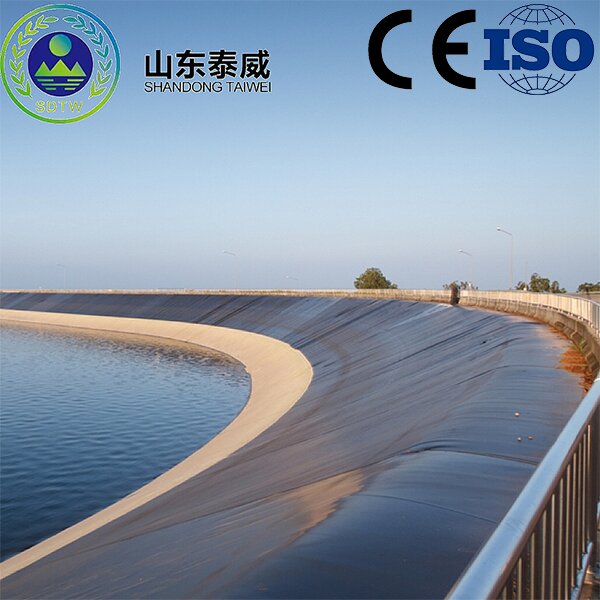

2.Pond and Reservoir Liners: It offers secure containment for water bodies, ensuring efficient water storage and preventing water loss due to seepage.

3.Mining and Chemical Tank Liners: The geomembrane provides reliable containment solutions for mining operations and chemical storage facilities, protecting the surrounding environment from contamination.

4.Agriculture and Aquaculture Applications: It is used in agricultural ponds, irrigation systems, and fish farming to prevent water seepage and manage water resources effectively.

5.Civil Engineering Projects: Our HDPE Geomembrane is widely used in canal lining, soil erosion control, and stormwater management, ensuring efficient water flow and preventing soil degradation.

HDPE Geomembrane Technical Parameter (GRI GM13 ASTM Standard) | ||||||||

Spec Properties | Test | GMS0.5 | GMS0.75 | GMS1.0 | GMS1.25 | GMS1.5 | GMS2.0 | GMS2.5 |

Thickness | D5199 | 0.5mm | 0.75mm | 1.00mm | 1 .25mm | 1.50mm | 2.00mm | 2.50mm |

Density (≥ g/cc) | D1505 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 |

Tensile Properties | D6693 Type IV | 8 kN/m 14 kN/m 12% 700% | 11 kN/m | 15 kN/m | 18 kN/m | 22 kN/m 40 kN/m 12% 700% | 29kN/m 53 KN/m 12% 700% | 37kN/m 67kN/m 12% 700% |

Tear Resistance (≥) | D 1004 | 64N | 93N | 125 N | 156N | 187N | 249 N | 311 N |

Puncture Resistance(≥) | D 4833 | 160N | 240N | 320 N | 400 N | 480N | 640 N | 800 N |

Stress Crack Resistance (≥) | D 5397 | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr |

Carbon Black Content | D 1603 | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% |

Carbon Black Dispersion | D 5596 | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) |

Oxidative Induction Time(OIT)(≥) (a)Standard OIT ——or—— | D 3895 D 5885 | 100 min | 100 min | 100 min | 100 min | 100 min | 100 min | 100 min |

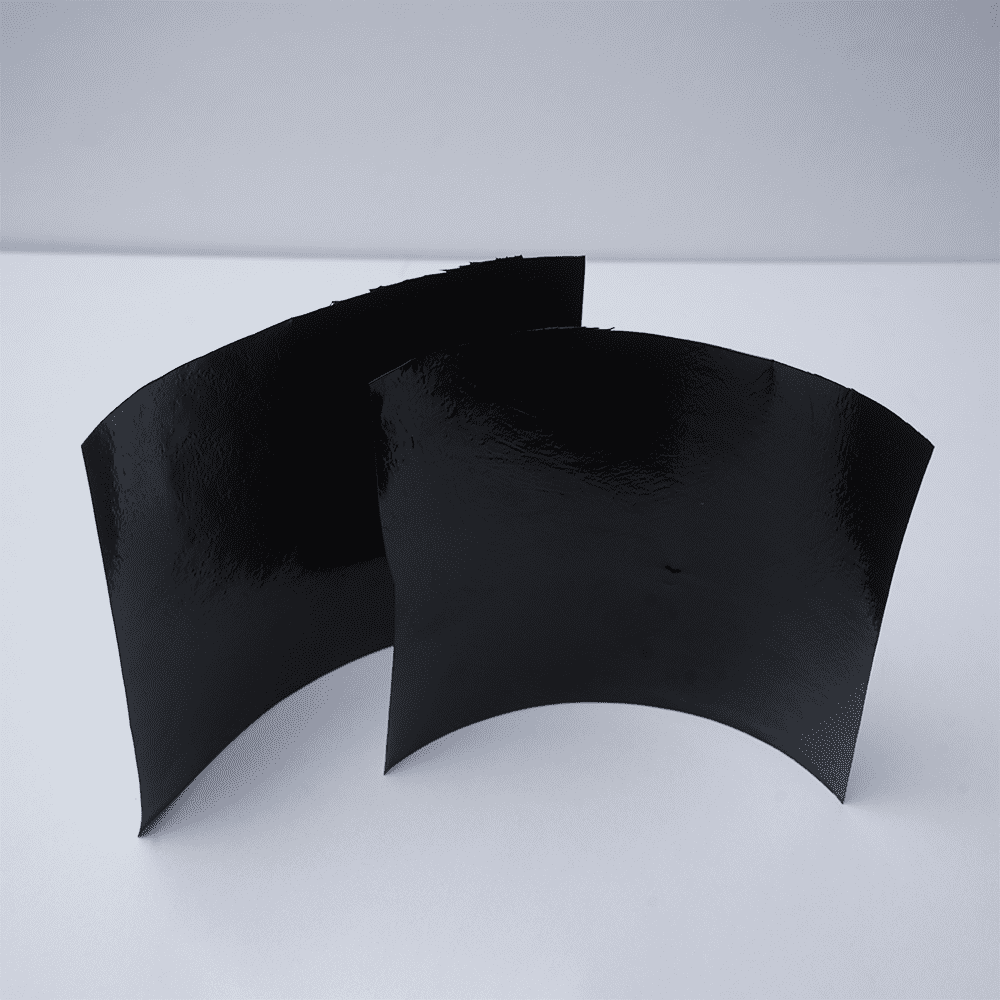

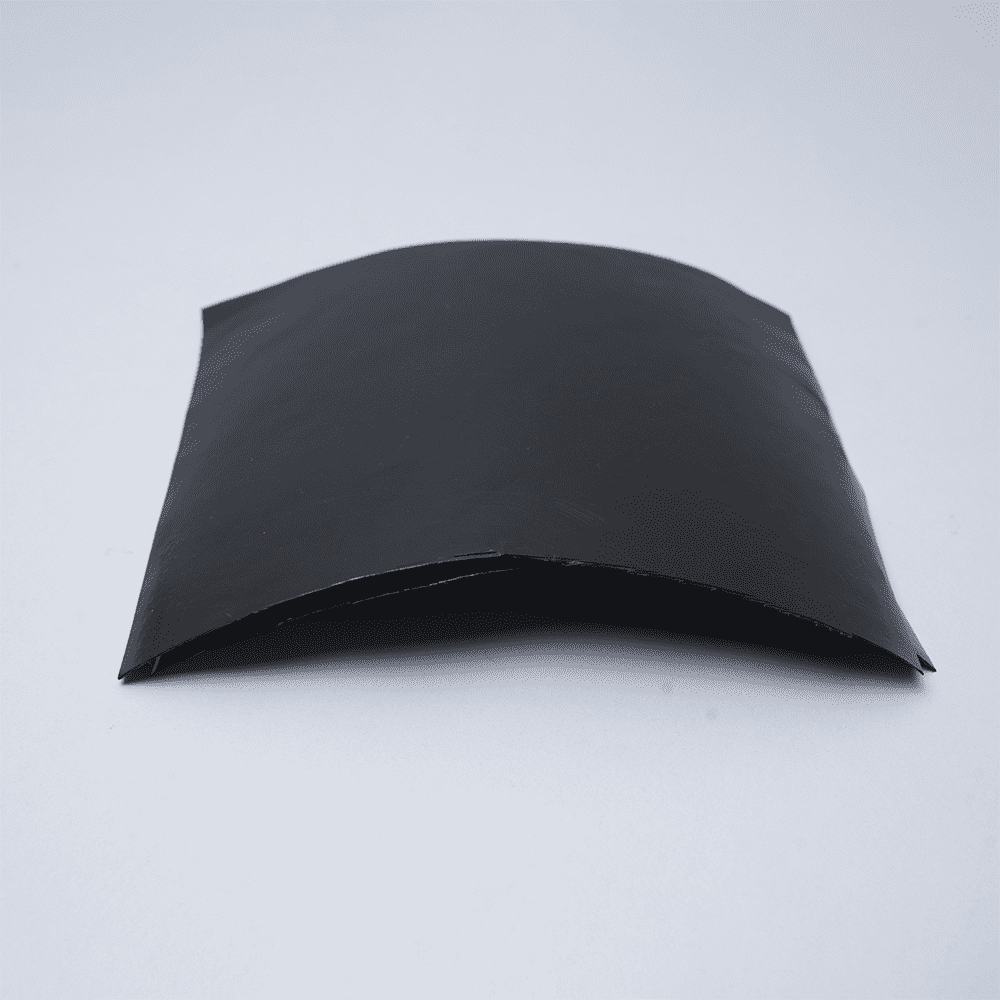

Packing of High Quality HDPE Geomembrane Pond Liner

Pond liner geotextile membrane for water seepage prevention HDPE Geomembrane

Usage Scenarios of High Quality HDPE Geomembrane Pond Liner

HDPE Geomembrane Technical Parameter (GRI GM13 ASTM Standard) | ||||||||

Spec Properties | Test | GMS0.5 | GMS0.75 | GMS1.0 | GMS1.25 | GMS1.5 | GMS2.0 | GMS2.5 |

Thickness | D5199 | 0.5mm | 0.75mm | 1.00mm | 1 .25mm | 1.50mm | 2.00mm | 2.50mm |

Density (≥ g/cc) | D1505 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 |

Tensile Properties | D6693 Type IV | 8 kN/m 14 kN/m 12% 700% | 11 kN/m | 15 kN/m | 18 kN/m | 22 kN/m 40 kN/m 12% 700% | 29kN/m 53 KN/m 12% 700% | 37kN/m 67kN/m 12% 700% |

Tear Resistance (≥) | D 1004 | 64N | 93N | 125 N | 156N | 187N | 249 N | 311 N |

Puncture Resistance(≥) | D 4833 | 160N | 240N | 320 N | 400 N | 480N | 640 N | 800 N |

Stress Crack Resistance (≥) | D 5397 | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr |

Carbon Black Content | D 1603 | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% |

Carbon Black Dispersion | D 5596 | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) |

Oxidative Induction Time(OIT)(≥) (a)Standard OIT ——or—— | D 3895 D 5885 | 100 min | 100 min | 100 min | 100 min | 100 min | 100 min | 100 min |

Related Products

Submitted successfully

We will contact you as soon as possible

Submitted successfully

We will contact you as soon as possible