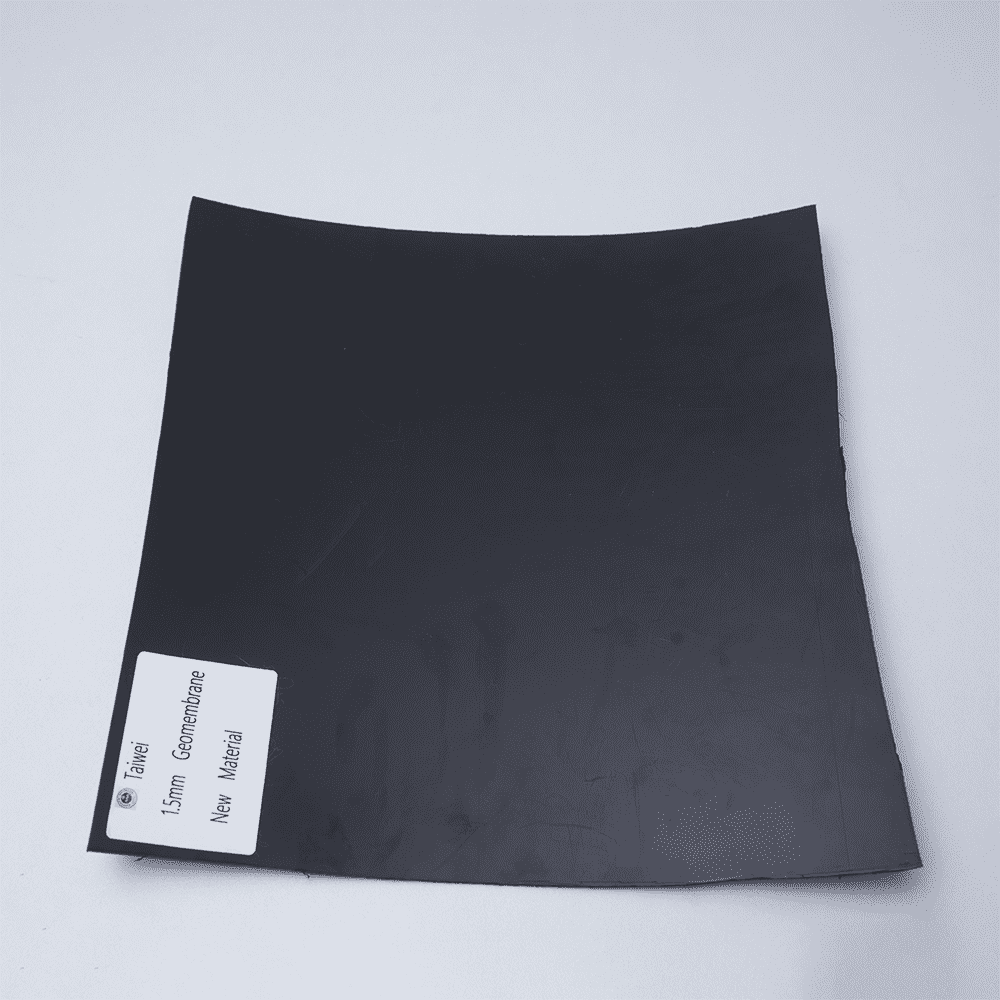

Special waterproofing for landfill sites HDPE Geomembrane

Product specifications;

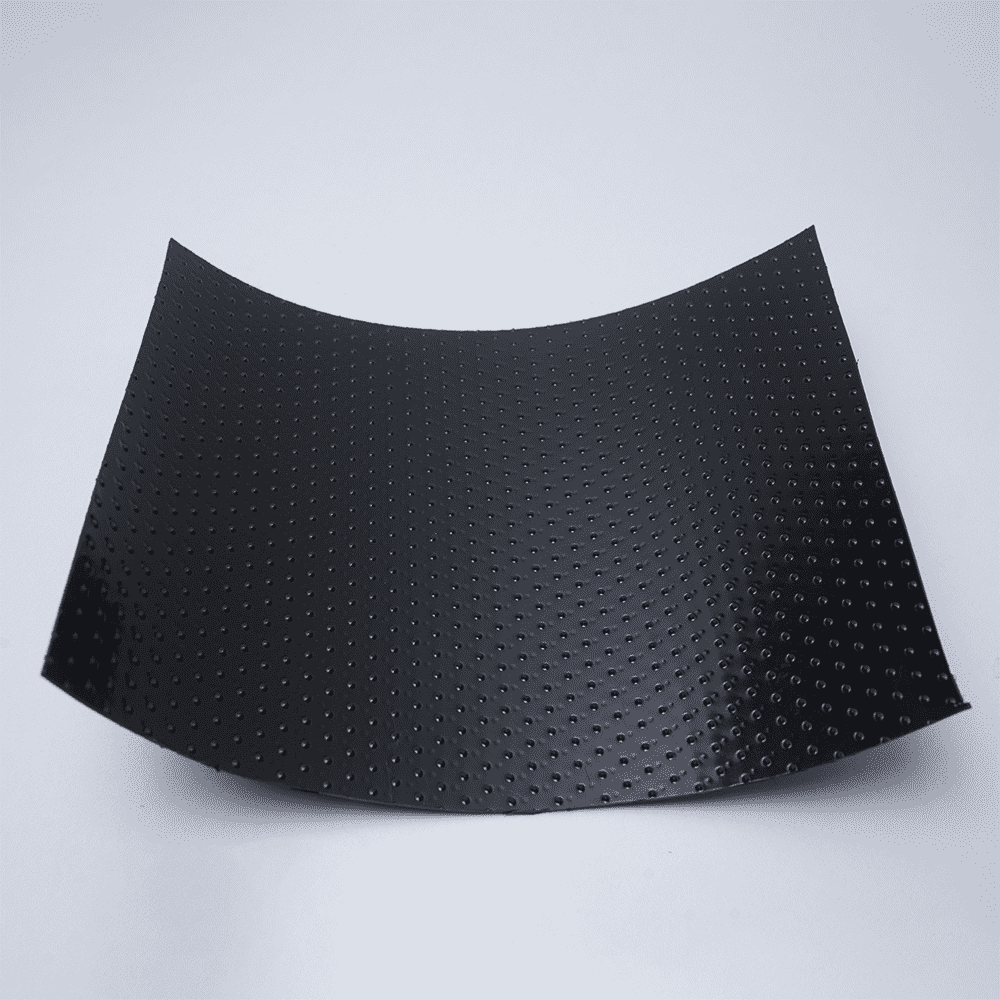

Materials; Mainly divided into: low-density polyethylene (LDPE) geomembrane, high-density polyethylene (HDPE) geomembrane, and EVA geomembrane.

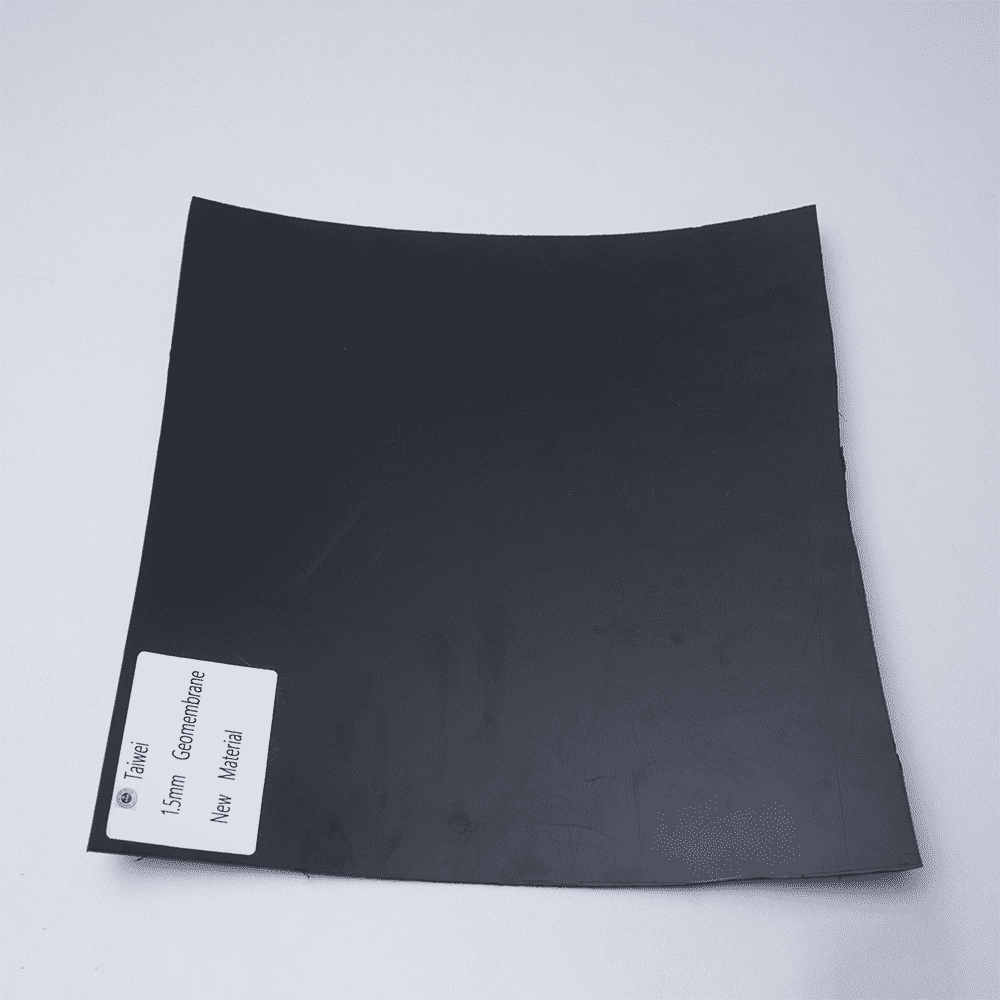

Thickness; 1.0-2.0mm

Wide width; 4-8 meters

If there are special requirements, such as packaging requirements (width, length, thickness), please inform customer service personnel

Special waterproofing for landfill sites HDPE Geomembrane

With entire specs of width and thickness, it has extraordinary resistance to environmental stress cracking and chemical corrosion, as properly as first-rate resistance to chemical corrosion. It has a giant temperature vary and a lengthy provider life, and is used in landfill sites, tailings storage sites, canal seepage prevention, dam seepage prevention, and subway engineering

Product characteristics;

According to countrywide standards, polyethylene movie with a thickness of 0.2m and a stabilizer used in hydraulic engineering can work for up to 40-50 years beneath smooth water prerequisites and 30-40 years below sewage conditions, relying on whether or not the plastic movie has misplaced its anti-seepage and water blocking off effect. Therefore, the carrier existence of the geomembrane is ample to meet the anti-seepage requirements of the dam.

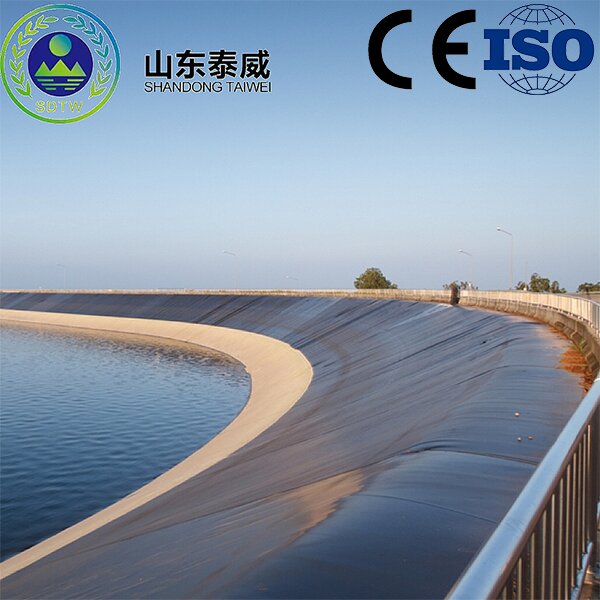

Application scope;

Environmental protection and hygiene engineering, water conservancy and geotechnical engineering, municipal engineering, landscaping, stone mining, aquaculture industry (fish pond, shrimp pond lining, etc.)

HDPE Geomembrane Technical Parameter (GRI GM13 ASTM Standard) | ||||||||

Spec Properties | Test | GMS0.5 | GMS0.75 | GMS1.0 | GMS1.25 | GMS1.5 | GMS2.0 | GMS2.5 |

Thickness | D5199 | 0.5mm | 0.75mm | 1.00mm | 1 .25mm | 1.50mm | 2.00mm | 2.50mm |

Density (≥ g/cc) | D1505 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 |

Tensile Properties | D6693 Type IV | 8 kN/m 14 kN/m 12% 700% | 11 kN/m | 15 kN/m | 18 kN/m | 22 kN/m 40 kN/m 12% 700% | 29kN/m 53 KN/m 12% 700% | 37kN/m 67kN/m 12% 700% |

Tear Resistance (≥) | D 1004 | 64N | 93N | 125 N | 156N | 187N | 249 N | 311 N |

Puncture Resistance(≥) | D 4833 | 160N | 240N | 320 N | 400 N | 480N | 640 N | 800 N |

Stress Crack Resistance (≥) | D 5397 | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr |

Carbon Black Content | D 1603 | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% |

Carbon Black Dispersion | D 5596 | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) |

Oxidative Induction Time(OIT)(≥) (a)Standard OIT ——or—— | D 3895 D 5885 | 100 min | 100 min | 100 min | 100 min | 100 min | 100 min | 100 min |

Packing of High Quality HDPE Geomembrane Pond Liner

Pond Liner geotextile membrane for water seepage prevention HDPE Geomembrane

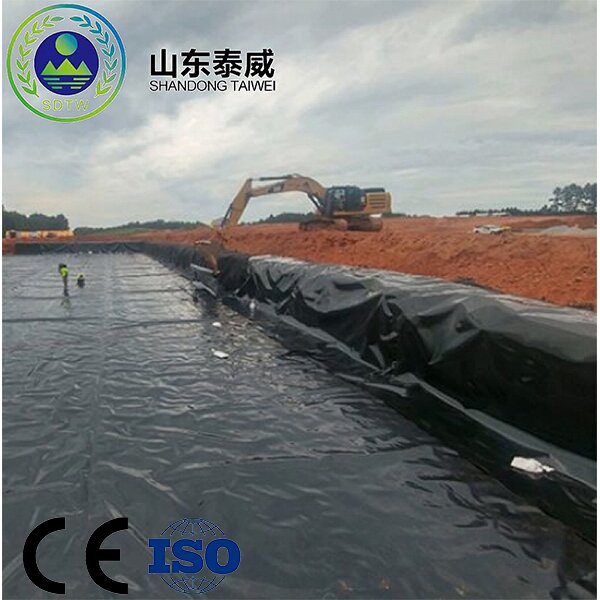

Usage Scenarios of High Quality HDPE Geomembrane Pond Liner

HDPE Geomembrane Technical Parameter (GRI GM13 ASTM Standard) | ||||||||

Spec Properties | Test | GMS0.5 | GMS0.75 | GMS1.0 | GMS1.25 | GMS1.5 | GMS2.0 | GMS2.5 |

Thickness | D5199 | 0.5mm | 0.75mm | 1.00mm | 1 .25mm | 1.50mm | 2.00mm | 2.50mm |

Density (≥ g/cc) | D1505 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 |

Tensile Properties | D6693 Type IV | 8 kN/m 14 kN/m 12% 700% | 11 kN/m | 15 kN/m | 18 kN/m | 22 kN/m 40 kN/m 12% 700% | 29kN/m 53 KN/m 12% 700% | 37kN/m 67kN/m 12% 700% |

Tear Resistance (≥) | D 1004 | 64N | 93N | 125 N | 156N | 187N | 249 N | 311 N |

Puncture Resistance(≥) | D 4833 | 160N | 240N | 320 N | 400 N | 480N | 640 N | 800 N |

Stress Crack Resistance (≥) | D 5397 | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr |

Carbon Black Content | D 1603 | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% |

Carbon Black Dispersion | D 5596 | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) |

Oxidative Induction Time(OIT)(≥) (a)Standard OIT ——or—— | D 3895 D 5885 | 100 min | 100 min | 100 min | 100 min | 100 min | 100 min | 100 min |