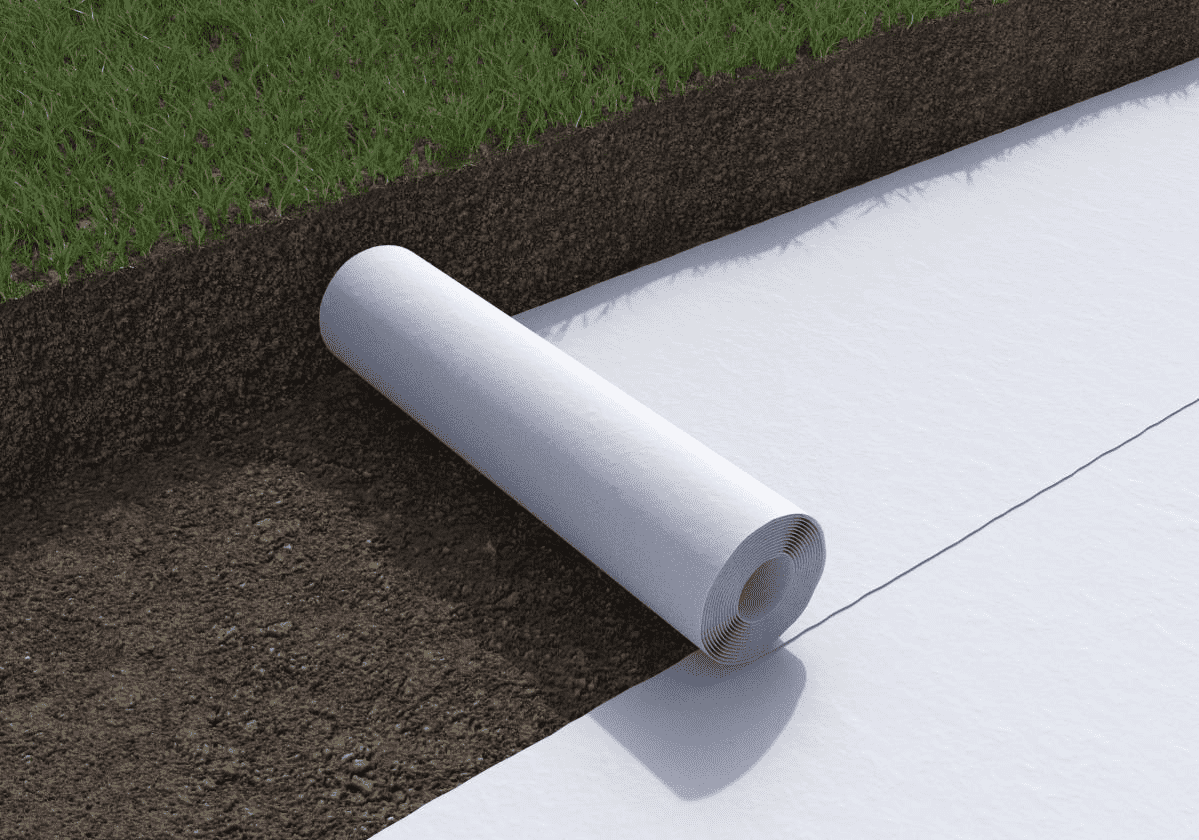

Nonwoven PET Geotextile For Road Landfill Projects

PET Geotextile Staple Fiber Needle Fabric Punched Nonwoven-Staple fiber needle-punched nonwoven geotextiles are made of PP or PET fast fibers and produced by non-woven technology. geotextiles have proper water conductivity. They create drainage channels within the soil, allowing excess gases and liquids to escape.

●Material: PET fiber

●Color: white, black, gray

●Length: 50m-100m

●Width: 0.5-6m

●Certificate: CE/ISO9001

●Type: Acupuncture

Nonwoven PET Geotextile For Road Landfill Projects

PET non-woven geotextiles have excellent anti-seepage and corrosion resistance, so that geotextiles are broadly used in railways, highways, tunnels, and coastal tidal flat initiatives for isolation, reverse filtration, reinforcement, protection, and drainage.

Product Features:

It is widely used in the reinforcement of asphalt pavement, cement concrete pavement and roadbed. It can be used on various difficult and curved road surfaces, which can minimize the value compared with ordinary road surfaces, prolong the life of the carrier, and prevent road reflection cracks;

The thickness of the product is appropriate, easy to mix with asphalt pavement, and form an isolation layer after combining with sticky layer oil, which has the characteristics of waterproof and warm;

Utilize the good air permeability and water permeability of the squatting geotextile to let the water flow through, thereby effectively retaining the loss of sand and soil.

The isolation layer between the ballast and the subgrade, or the isolation layer between the subgrade and the tender base.

Application:

The Nonwoven PET Geotextile For Road Landfill Projects is mainly characterized by relatively high strength, which can last for a long time in soil with different pH and acid water;

Function:

The water permeability is quite good, and it has a accurate water seepage function, due to the fact there are gaps in the behavior;

Reverse filtration and drainage: Short fiber geotextile broadly speaking replaces the standard cloth gravel layer in the element of reverse filtration and drainage. The drainage capability of the geotextile is at once proportional to the thickness of the geotextile. Generally speaking, the thicker the thickness, the higher the drainage capability of the geotextile.

Strengthen the bendy pavement, restore the cracks on the road, and stop the pavement from reflecting cracks.

The thickness of the product is appropriate, effortless to mix with asphalt pavement, and structure an isolation layer after combining with sticky layer oil, which has the features of water resistant and warmness preservation;

Specifications

Staple Fiber Needled Non-woven Geotextile Technical Specifications ( GB/T17638-1998) | |||||||||||||

No. | Item | Specifications | Note | ||||||||||

100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 800 | |||

1 | Unit area mass deviation | -8 | -8 | -8 | -8 | -7 | -7 | -7 | -7 | -6 | -6 | -6 |

|

2 | Thickness mm≥ | 0.9 | 1.3 | 1.7 | 2.1 | 2.4 | 2.7 | 3.0 | 3.3 | 3.6 | 4.1 | 5.0 | |

3 | Width deviation | -0.5 | |||||||||||

4 | Breaking strength | 2.5 | 4.5 | 6.5 | 8.0 | 9.5 | 11 | 12.5 | 14.0 | 16.0 | 19.0 | 25.0 | Vertical and horizontal |

5 | Elongation at break % | 20-100 | |||||||||||

6 | CBR bursting strength | 0.3 | 0.6 | 0.8 | 1.2 | 1.4 | 1.8 | 2.1 | 2.4 | 2.7 | 3.2 | 4.0 |

|

7 | Equivalent aperture | 0.07-0.2 |

| ||||||||||

8 | Vertical permeability coefficient | K*(10-1~10-3) | K=1.0-9.9 | ||||||||||

9 | Tear strength | 0.08 | 0.12 | 0.16 | 0.20 | 0.24 | 0.28 | 0.33 | 0.38 | 0.42 | 0.46 | 0.6 | Vertical and horizontal |

Packing of Nonwoven PET Geotextile For Road Landfill Projects

You can freely choose PE film or PP woven bag for outer packaging, and there are paper tubes of different sizes inside the product for you to choose freely.

FAQ

1) How can I place an order?

A: You can contact us by email or WhatsApp us for your order details, or place an order online.

2) How can I pay you?

A: After you confirm our PI, we will ask you to pay. T/T and Paypal are our most commonly used ways.

3) What is the ordering procedure?

A: First we discuss order details, production details by email or WhatsApp. Then we send you a PI for your confirmation. You will be required to pay full payment or deposit in advance before we go into production. After receiving the deposit, we start to process the order. If we don't have stock, we usually need 7-15 days. Before production is finished, we will contact you for shipment details and balance payment. After the payment is completed, we start to prepare the shipment for you.

4) How do you deal with when your customers receive defective products?

A: replacement. If there are some defective items, we usually credit to our customer or replace in next shipment.

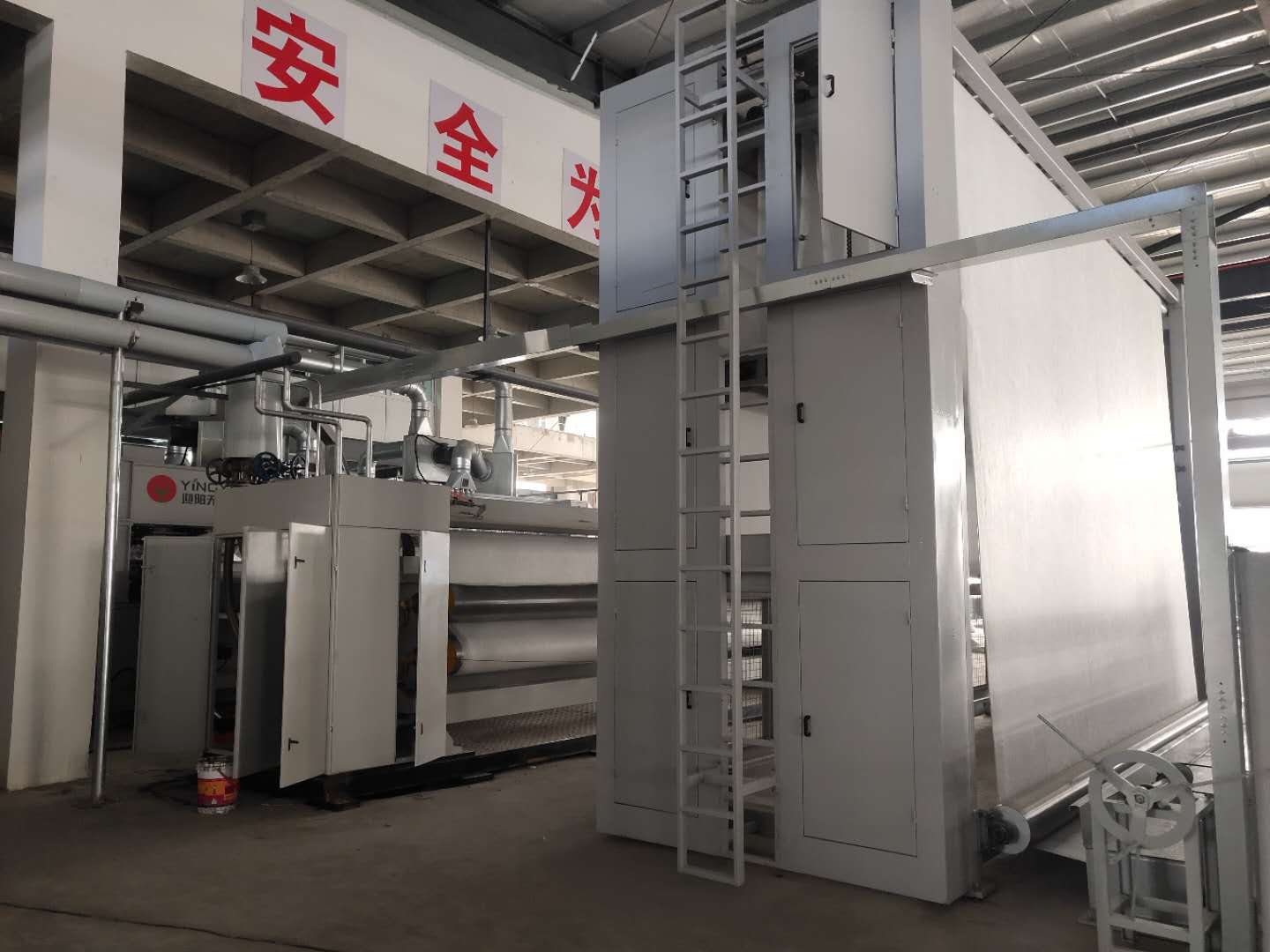

5) How do you check all the goods on the production line?

A: We have on-site inspection and finished product inspection. When the goods enter the next step of production procedure, we will check the goods.

Staple Fiber Needled Non-woven Geotextile Technical Specifications ( GB/T17638-1998) | |||||||||||||

No. | Item | Specifications | Note | ||||||||||

100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 800 | |||

1 | Unit area mass deviation | -8 | -8 | -8 | -8 | -7 | -7 | -7 | -7 | -6 | 6 | -6 |

|

2 | Thickness mm≥ | 0.9 | 1.3 | 1.7 | 2.1 | 2.4 | 2.7 | 3.0 | 3.3 | 3.6 | 4.1 | 5.0 | |

3 | Width deviation | -0.5 | |||||||||||

4 | Breaking strength | 2.5 | 4.5 | 6.5 | 8.0 | 9.5 | 11 | 12.5 | 14.0 | 16.0 | 19.0 | 25.0 | Vertical and horizontal |

5 | Elongation at break % | 20-100 | |||||||||||

6 | CBR bursting strength | 0.3 | 0.6 | 0.8 | 1.2 | 1.4 | 1.8 | 2.1 | 2.4 | 2.7 | 3.2 | 4.0 |

|

7 | Equivalent aperture | 0.07-0.2 |

| ||||||||||

8 | Vertical permeability coefficient | K*(10-1~10-3) | K=1.0-9.9 | ||||||||||

9 | Tear strength | 0.08 | 0.12 | 0.16 | 0.20 | 0.24 | 0.28 | 0.33 | 0.38 | 0.42 | 0.46 | 0.6 | Vertical and horizontal |