PET Geotextile Manufacturer

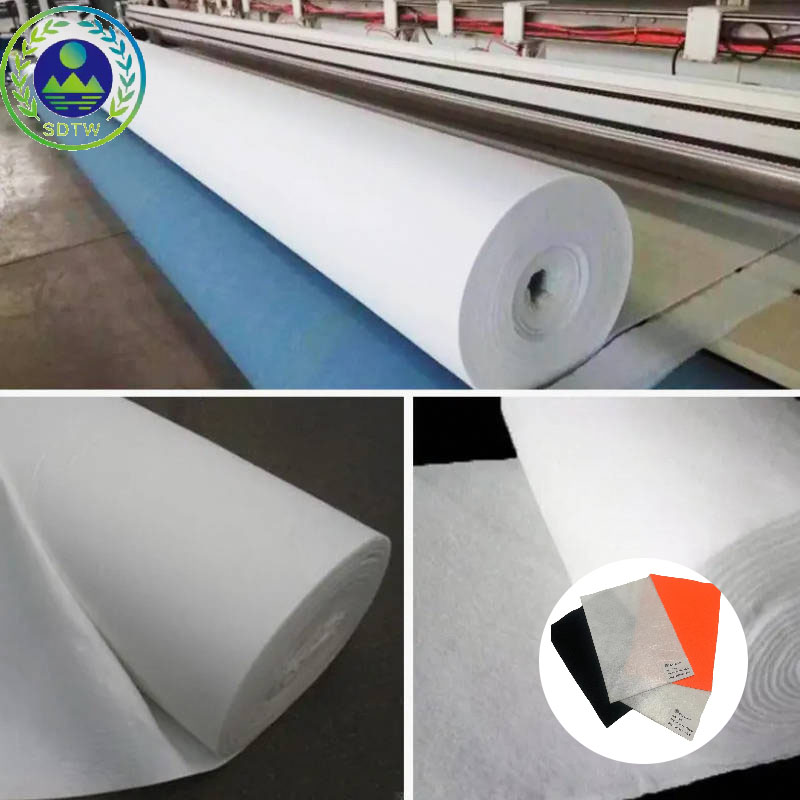

PET Geotextile Manufacturer -PET Geotextile the usage of PET as uncooked material, adopts soften spinning, air-laid and needle-punching consolidation method to produce geotextiles with three-dimensional pores.High mechanical index, suitable creep performance; sturdy corrosion resistance, creating older resistance, extraordinarily properly warmth resistance, wonderful hydraulic performance.

●Material:Polyester

●Color: White,Black,Orange

●Unit weight:100gsm-800gsm

●Length: 50m-100m

●Width: 1-6.2m

●Certificate: CE /ISO9001

●Type: Needle Punched

Product features

●Permeability and aircraft drainage - the geotextile is thick and needle-punched, has top aircraft drainage and vertical water permeability, and can nonetheless keep this overall performance after many years;

●Creep resistance - the creep resistance of geotextiles is higher than different geotextiles, so the long-term impact is good. It is resistant to the erosion of frequent chemical elements in the soil and the corrosion of fuel and diesel oil;

●Extensibility - Geotextile has a true elongation charge beneath a sure stress, so that it can adapt to uneven and irregular base surfaces;

Application:

●Isolation layer between artificial fill, rockfill or material field and foundation, isolation between different permafrost layers, reverse filtration and reinforcement.

●The filter layer of the initial upstream dam surface of the ash storage dam or tailings dam, and the filter layer of the drainage system in the backfill soil of the retaining wall.

●The filter layer around the underground drainage pipe or the gravel drainage ditch.

●The filter layer of water wells, relief wells or baroclinic pipes in water conservancy projects.

Product implementation standards: national standard (GB/T 17639-2008)

| Filament Spunbonded Needled Non-woven Geotextile Technical Specifications | ||||||||||

| Item | Index | |||||||||

| Index breaking strength(KN/m) | 4.5 | 7.5 | 10 | 15 | 20 | 25 | 30 | 40 | 50 | |

| 1 | Vertical and horizontal rupture strength / (KN/ m) | 4.5 | 7.5 | 10 | 15 | 20 | 25 | 30 | 40 | 50 |

| 2 | Vertical and horizontal standard strength corresponding to elongation % | 40-80 | ||||||||

| 3 | CBR bursting strength /KN | 0.8 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 |

| 4 | Vertical and horizontal tearing strength /KN | 0.14 | 0.21 | 0.28 | 0.42 | 0.56 | 0.70 | 0.82 | 1.10 | 1.25 |

| 5 | Equivalent aperture O90(95)>/mm | 0.05-0.20 | ||||||||

| 6 | Vertical permeability coefficient | K*(10-1~10-3)and K=1.0~9.9 | ||||||||

| 7 | Thickness / mm≥ | 0.8 | 1.2 | 1.6 | 2.2 | 2.8 | 3.4 | 4.2 | 5.5 | 6.8 |

| 8 | Width deviation | -0.5 | ||||||||

| 9 | Unit area mass deviation | -5 | ||||||||

Packing of PET Geotextile

You can freely choose PE film or PP woven bag for outer packaging, and there are paper tubes of different sizes inside the product for you to choose freely.

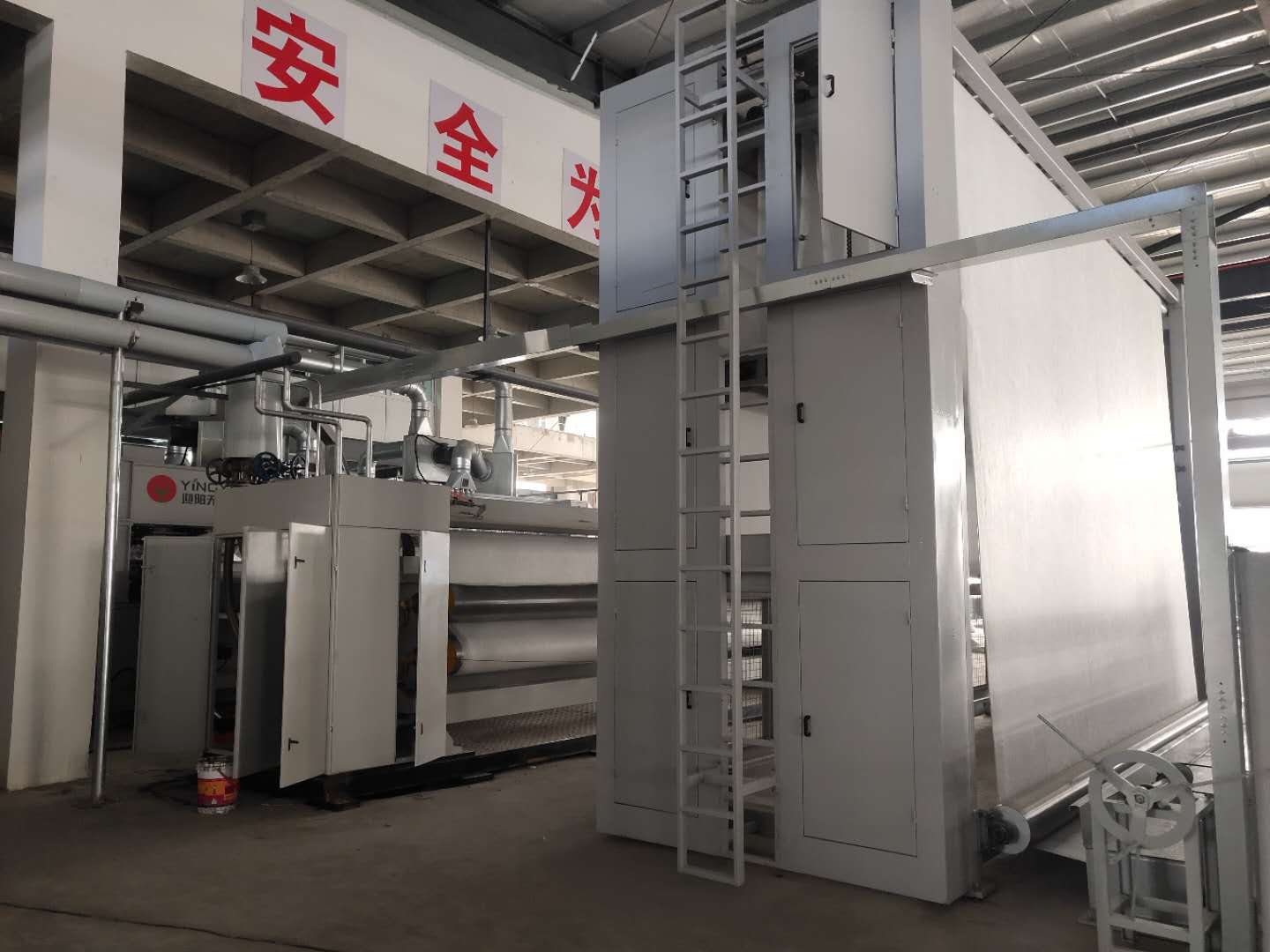

Strength of the company

The employer has impartial geotextile manufacturing equipment, skilled technical personnel, a giant manufacturing group and a expert after-sales team. The annual output of geotextiles is greater than 30 million rectangular meters. Products are extensively used in landfills, synthetic lakes, rivers, canals, subways, basements, highways, railways, tunnels and different projects. It has been identified as a incredible fabric provider by way of the country wide authority and bought overseas.