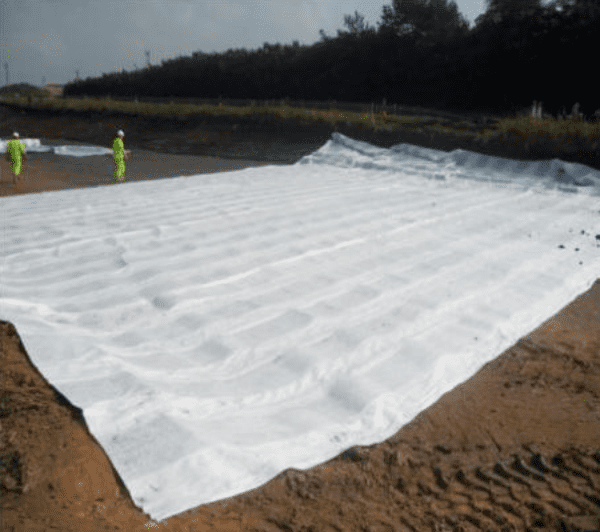

Landscape PP Geotextile

Water conservancy engineering prevention and permeability Polypropylene Geotextile resistance, splendid water permeability, immoderate tensile strength, and reachable installation. It is greatly used in fields such as earthwork engineering, water conservancy engineering, twin carriageway engineering, railway engineering, etc.

Material: PP

Color: white, black, green, orange, statistics coloration customization

Specifications: 100g-800g

Length: 50-200m

Certificate: CE/ISO9001

Reinforced and constant non-woven geotextile

Product introduction:

Short fiber geotextile is a type of geosynthetic material usually used in civil engineering and geotechnical applications. It is made from synthetic fibers that are mechanically bonded or needle-punched together to structure a constant cloth structure.

Product characteristics:

1. Filtration: The material form of fast fiber geotextile permits the drainage of water by utilizing the ability of a comprehensive performance approach while retaining soil particles. This filtration property makes it widely used in areas such as drainage structures and erosion control, where it helps prevent soil clogging and provides very good water flow.

2.Separation: Short fiber geotextiles can serve as separators between large layers of soil or properties with unique characteristics. By stopping the mixing of these layers, it continues the integrity of their roles and enhances normal stability. Common examples include its use in road construction, where it separates the road base from the asphalt or concrete layer.

3. Reinforcement: The super tensile force of fast fiber geotextile provides reinforcement to soil and tissue materials. It will improve its load-bearing capacity and help control settlement or deformation. In components such as slope stabilization, retaining walls, and landfill liners, this property is the main material that is really recommended.

4. Protection: Short fiber geotextiles can be used to protect geomembranes, waterproof layers and first-level sensitive sources from mechanical damage during reinforcement or long-term use. It acts as a cushioning layer to protect against punctures or abrasions.

5. Durability: Rapid fiber geotextiles are made of synthetic fibers that resist degradation by UV radiation, chemicals and natural factors. It has a long lifespan, ensuring it remains effective over time.

Application scope:

1. Highway and railway construction: used as isolation and filter layer in the base layer of toll highways, roadbed, and railroad padding system.

2. Erosion prevention and control: used for shoreline protection, river embankments and steep slope stabilization, inserting off soil erosion and advertising of vegetation growth.

3. Drainage system: Combined with underground drainage system, septic tank drainage field, and rainwater administration planning, the drainage and filtration of human physique water can be realized.

4. Landfill and Waste Management: Used as a defensive boundary for landfill lines, capping, and waste redress buildings to deal with soil contamination.

5. Landscaping and agriculture: used for weeding, soil consolidation, reinforcement, etc. in landscaping. Used in agriculture for erosion control, irrigation, pocket filtering, and pond lining safety.

Specifications

Staple Fiber Needled Non-woven Geotextile Technical Specifications ( GB/T17638-1998) | |||||||||||||

No. | Item | Specifications | Note | ||||||||||

100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 800 | |||

1 | Unit area mass deviation | -8 | -8 | -8 | -8 | -7 | -7 | -7 | -7 | -6 | -6 | -6 | |

2 | Thickness mm≥ | 0.9 | 1.3 | 1.7 | 2.1 | 2.4 | 2.7 | 3.0 | 3.3 | 3.6 | 4.1 | 5.0 | |

3 | Width deviation | -0.5 | |||||||||||

4 | Breaking strength | 2.5 | 4.5 | 6.5 | 8.0 | 9.5 | 11 | 12.5 | 14.0 | 16.0 | 19.0 | 25.0 | Vertical and horizontal |

5 | Elongation at break % | 20-100 | |||||||||||

6 | CBR bursting strength | 0.3 | 0.6 | 0.8 | 1.2 | 1.4 | 1.8 | 2.1 | 2.4 | 2.7 | 3.2 | 4.0 | |

7 | Equivalent aperture | 0.07-0.2 | |||||||||||

8 | Vertical permeability coefficient | K*(10-1~10-3) | K=1.0-9.9 | ||||||||||

9 | Tear strength | 0.08 | 0.12 | 0.16 | 0.20 | 0.24 | 0.28 | 0.33 | 0.38 | 0.42 | 0.46 | 0.6 | Vertical and horizontal |

Geotextile packaging

You can freely choose PE film or PP woven bag for outer packaging, and there are paper tubes of different sizes inside the product for you to choose freely.

Related Products

Submitted successfully

We will contact you as soon as possible

Submitted successfully

We will contact you as soon as possible