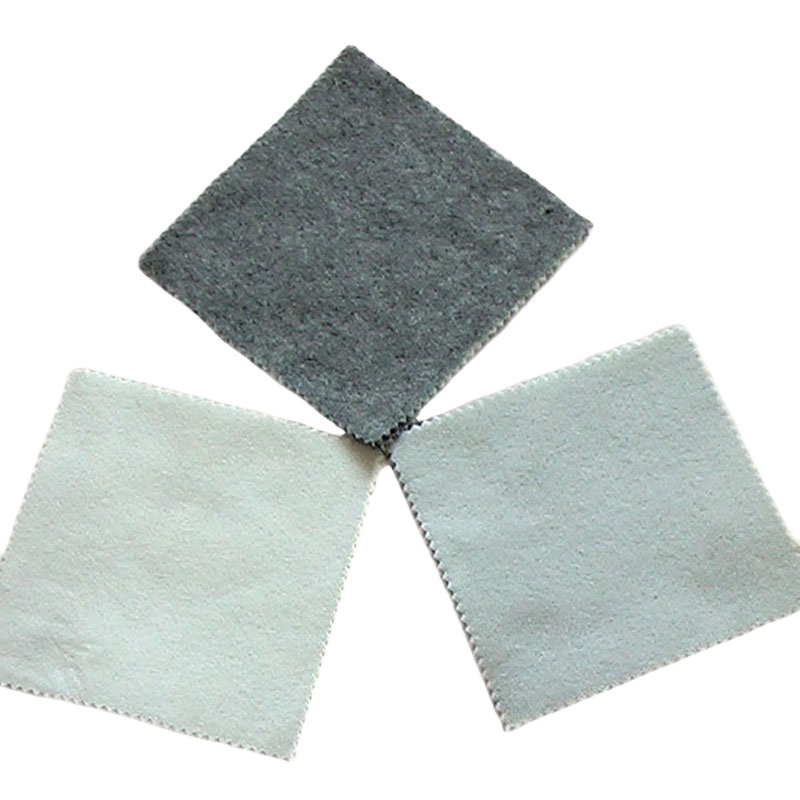

Polypropylene Geotextile White Stable Fiber Nonwoven Fabric

Polypropylene Geotextile White Stable Fiber Nonwoven Fabric-Staple-fiber needle-punched non-woven geotextiles can be used as reinforcement materials for railways and roads. The construction is simple-light in weight, easy to use, simple in construction, and can effectively diffuse, transfer or decompose concentrated stress and prevent soil from being damaged by external forces.

●Material: Polypropylene fiber

●Color: white, black, gray

●Length: 50m-100m

●Width: 0.5-6m

●Certificate: CE/ISO9001

●Type: Acupuncture

Polypropylene Geotextile White Stable Fiber Nonwoven Fabric

Staple-fiber needle-punched geotextiles are widely used in the reinforcement of asphalt pavement, cement concrete pavement and roadbed. The surface is rough and not easy to slide.

Product Features:

Easy construction and good application effect. Generally, the fiber filaments of geotextiles are easily lifted by vehicle tires, causing hanging threads, and even being rolled up in severe cases, causing displacement and structural damage of geotextiles.

Reinforcement: Use needle-punched geotextiles to decorate the tensile strength and deformation resistance of the soil, so that the balance of the building structure is greater and the quality of the soil is improved.

Geotextile has good water conductivity, it can form a drainage channel inside the soil, and discharge excess liquid and gas in the soil structure.

Effectively diffuse, transfer or decompose the concentrated stress to prevent the soil from being damaged by external forces.

Application:

The product has excellent water permeability, filterability and durability, and can be widely used in railways, highways, sports halls, dams, hydraulic structures, tunnels, coastal tidal flats, reclamation, environmental protection and other projects.

Function:

Effectively diffuse, transmit or decompose the concentrated stress to prevent the soil from being damaged by external forces.

Utilize the precise air and water permeability of needle-punched geotextiles to allow water to leak through, effectively retain soil particles, spun yarns, small stones, etc., and maintain the stability of water and soil engineering.

Anti-ultraviolet, anti-freeze, anti-chemical corrosion and anti-biological damage;

Use geotextiles to enhance the tensile strength and deformation resistance of the soil, enhance the stability of the building structure, and improve the quality of the soil.

Specifications

Staple Fiber Needled Non-woven Geotextile Technical Specifications ( GB/T17638-1998) | |||||||||||||

No. | Item | Specifications | Note | ||||||||||

100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 800 | |||

1 | Unit area mass deviation | -8 | -8 | -8 | -8 | -7 | -7 | -7 | -7 | -6 | -6 | -6 |

|

2 | Thickness mm≥ | 0.9 | 1.3 | 1.7 | 2.1 | 2.4 | 2.7 | 3.0 | 3.3 | 3.6 | 4.1 | 5.0 | |

3 | Width deviation | -0.5 | |||||||||||

4 | Breaking strength | 2.5 | 4.5 | 6.5 | 8.0 | 9.5 | 11 | 12.5 | 14.0 | 16.0 | 19.0 | 25.0 | Vertical and horizontal |

5 | Elongation at break % | 20-100 | |||||||||||

6 | CBR bursting strength | 0.3 | 0.6 | 0.8 | 1.2 | 1.4 | 1.8 | 2.1 | 2.4 | 2.7 | 3.2 | 4.0 |

|

7 | Equivalent aperture | 0.07-0.2 |

| ||||||||||

8 | Vertical permeability coefficient | K*(10-1~10-3) | K=1.0-9.9 | ||||||||||

9 | Tear strength | 0.08 | 0.12 | 0.16 | 0.20 | 0.24 | 0.28 | 0.33 | 0.38 | 0.42 | 0.46 | 0.6 | Vertical and horizontal |

Packing of Polypropylene Geotextile White Stable Fiber Nonwoven Fabric

You can freely choose PE film or PP woven bag for outer packaging, and there are paper tubes of different sizes inside the product for you to choose freely.

FAQ

1. Who are we?

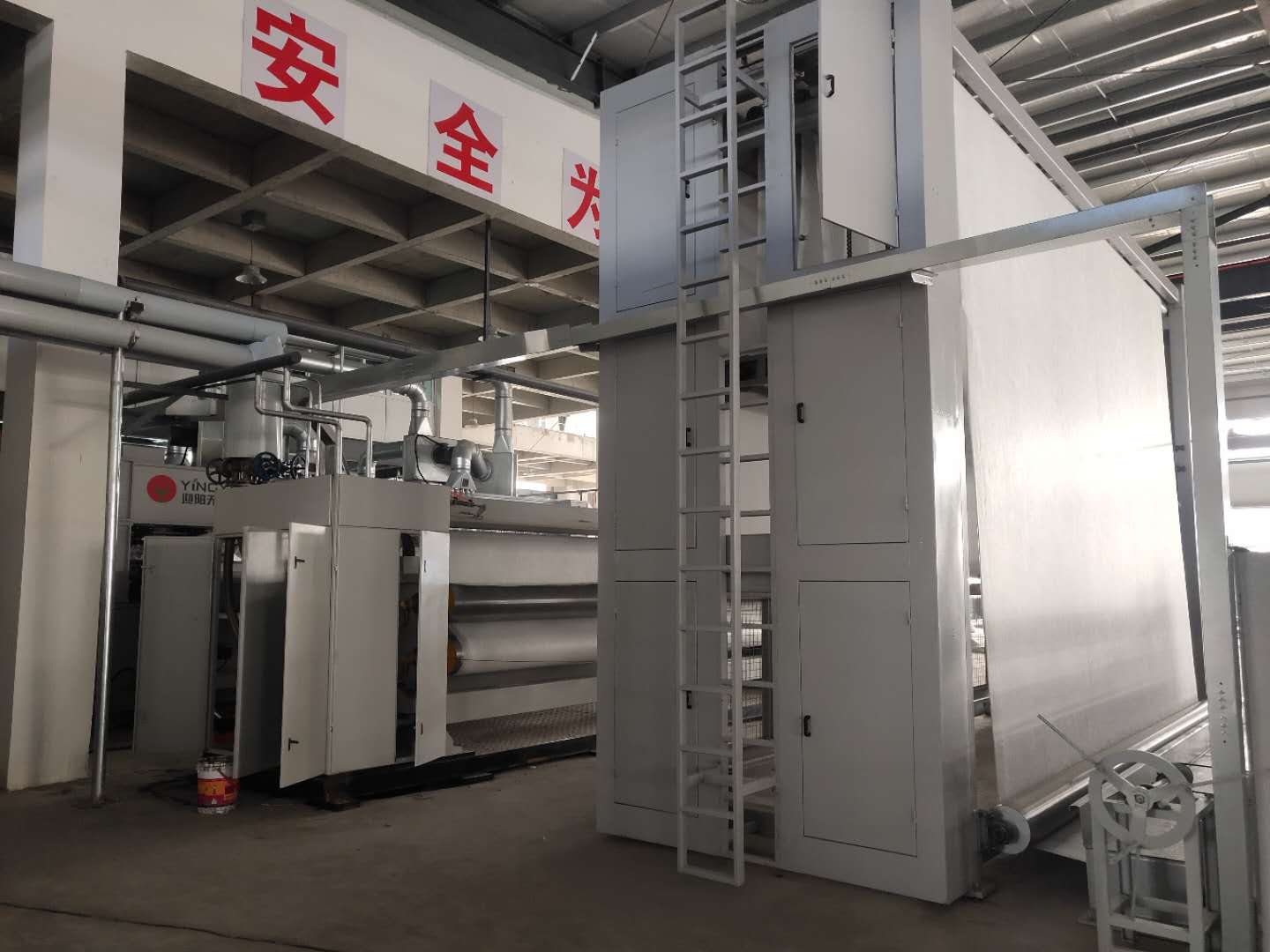

Our headquarter is located in Shandong, China, and we are a professional company engaged in the R&D, production and sales of geosynthetics.

2. How can we guarantee the quality?

Always a pre-production sample before mass production;

Always carry out final inspection before shipment;

3. What can you buy from us?

Geotextile, geomembrane, bentonite waterproof blanket GCL, geogrid

4. Why should you buy from us not from other suppliers?

A developer and manufacturer of geotextiles and geosynthetics, near the port and convenient transportation.

Strict quality assurance and QC system

ISO, CE certification;

5. What services can we provide?

Accepted delivery terms: FOB, CFR, CIF;

Accepted Payment Currency: USD,RMB;

Accepted payment methods: wire transfer, Paypal.

Language: English, Chinese

Staple Fiber Needled Non-woven Geotextile Technical Specifications ( GB/T17638-1998) | |||||||||||||

No. | Item | Specifications | Note | ||||||||||

100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 800 | |||

1 | Unit area mass deviation | -8 | -8 | -8 | -8 | -7 | -7 | -7 | -7 | -6 | 6 | -6 |

|

2 | Thickness mm≥ | 0.9 | 1.3 | 1.7 | 2.1 | 2.4 | 2.7 | 3.0 | 3.3 | 3.6 | 4.1 | 5.0 | |

3 | Width deviation | -0.5 | |||||||||||

4 | Breaking strength | 2.5 | 4.5 | 6.5 | 8.0 | 9.5 | 11 | 12.5 | 14.0 | 16.0 | 19.0 | 25.0 | Vertical and horizontal |

5 | Elongation at break % | 20-100 | |||||||||||

6 | CBR bursting strength | 0.3 | 0.6 | 0.8 | 1.2 | 1.4 | 1.8 | 2.1 | 2.4 | 2.7 | 3.2 | 4.0 |

|

7 | Equivalent aperture | 0.07-0.2 |

| ||||||||||

8 | Vertical permeability coefficient | K*(10-1~10-3) | K=1.0-9.9 | ||||||||||

9 | Tear strength | 0.08 | 0.12 | 0.16 | 0.20 | 0.24 | 0.28 | 0.33 | 0.38 | 0.42 | 0.46 | 0.6 | Vertical and horizontal |

Related Products

Submitted successfully

We will contact you as soon as possible

Submitted successfully

We will contact you as soon as possible