Short filament geotextile drainage isolation and consolidation project

Spunbonded nonwoven

Material: PET/PP

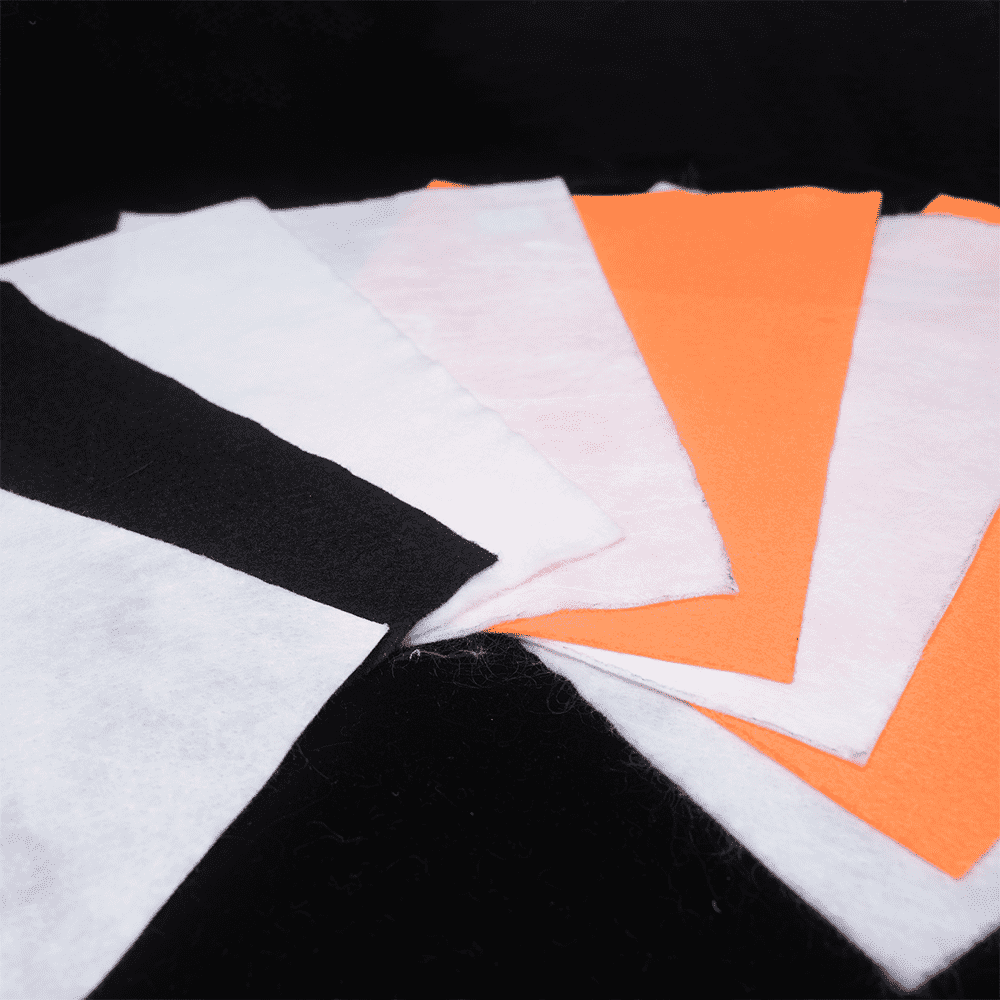

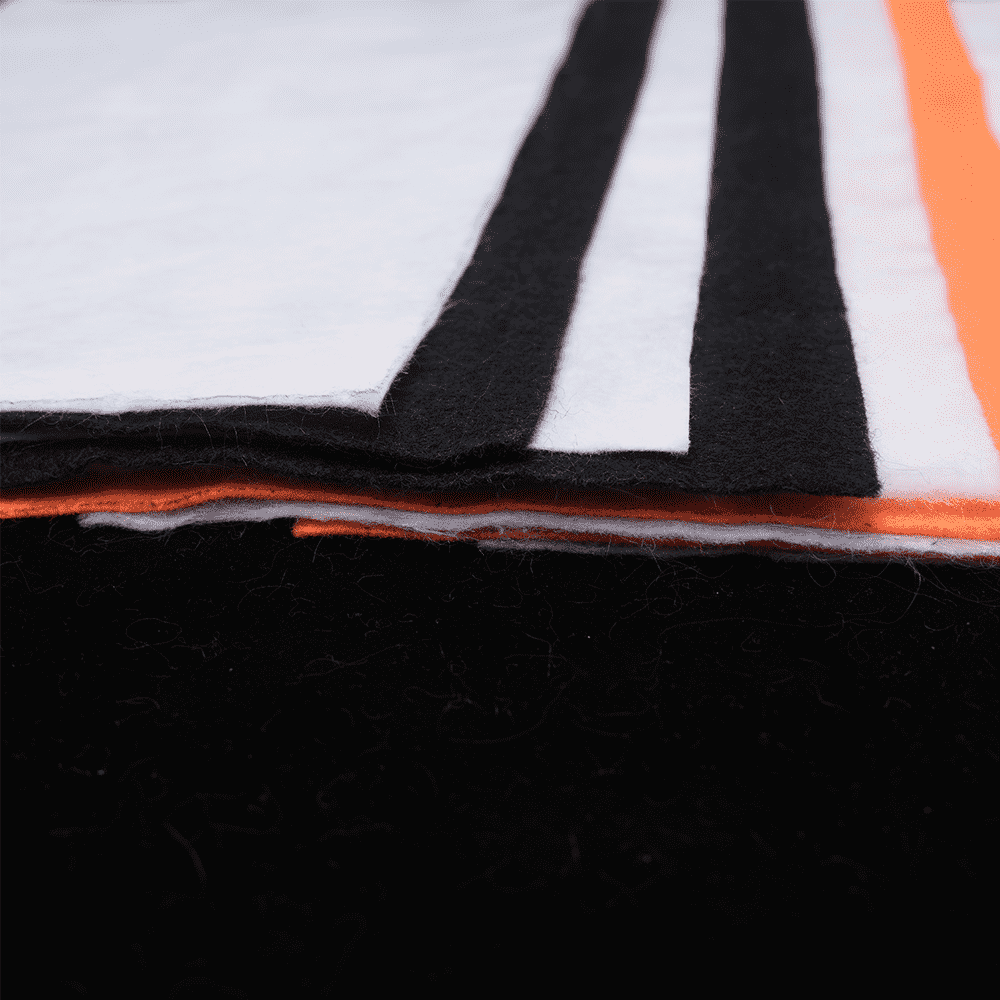

Colors: white, black, green, orange, personalized for statistical coloring

Specification: 100g-800g

Length: 50-100m

Certificate: CE/ISO9001

Support personalized hues and width lengths. Please inform purchaser carrier if there are any different necessities

Short filament geotextile drainage isolation and consolidation project

Product introduction;

Geotextile fabrics, also known as geosynthetics or geotextiles, are specialized materials designed for use in civil engineering and construction projects. These fabrics are made from synthetic fibers and are engineered to exhibit excellent physical and mechanical properties.

One commonly used type of geotextile fabric is the non-woven geotextile. This fabric is manufactured by layering and bonding synthetic fibers together, rather than weaving them. Non-woven geotextiles have high tensile strength, durability, and resistance to punctures, making them an ideal choice for various applications.

Product characteristics;

short filament geotextiles also offer excellent hydraulic characteristics. They allow water to pass through while retaining soil particles, preventing soil erosion and ensuring proper drainage.

Key advantages of short filament geotextile fabrics include:

1.Enhanced soil stability and reinforcement

2.Improved filtration and separation

3.Effective erosion control and drainage

4.Increased longevity of civil engineering structures

5.Cost-effective solution compared to traditional construction methods

Overall, short filament geotextiles provide an efficient and sustainable solution for various engineering applications. Their versatility, durability, and performance make them a preferred choice for professionals in the construction industry.

Application scope;

Short filament geotextiles are commonly used in the construction of roads, railways, embankments, and retaining walls. They are placed between different layers of soil or aggregate materials to prevent mixing and promote stability. These fabrics effectively distribute the load and provide reinforcement, improving the overall performance and lifespan of the structures.

Specifications

Staple Fiber Needled non-woven geotextile Technical Specifications ( GB/T17638-1998) | |||||||||||||

No. | Item | Specifications | Note | ||||||||||

100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 800 | |||

1 | Unit area mass deviation | -8 | -8 | -8 | -8 | -7 | -7 | -7 | -7 | -6 | -6 | -6 |

|

2 | Thickness mm≥ | 0.9 | 1.3 | 1.7 | 2.1 | 2.4 | 2.7 | 3.0 | 3.3 | 3.6 | 4.1 | 5.0 | |

3 | Width deviation | -0.5 | |||||||||||

4 | Breaking strength | 2.5 | 4.5 | 6.5 | 8.0 | 9.5 | 11 | 12.5 | 14.0 | 16.0 | 19.0 | 25.0 | Vertical and horizontal |

5 | Elongation at break % | 20-100 | |||||||||||

6 | CBR bursting strength | 0.3 | 0.6 | 0.8 | 1.2 | 1.4 | 1.8 | 2.1 | 2.4 | 2.7 | 3.2 | 4.0 |

|

7 | Equivalent aperture | 0.07-0.2 |

| ||||||||||

8 | Vertical permeability coefficient | K*(10-1~10-3) | K=1.0-9.9 | ||||||||||

9 | Tear strength | 0.08 | 0.12 | 0.16 | 0.20 | 0.24 | 0.28 | 0.33 | 0.38 | 0.42 | 0.46 | 0.6 | Vertical and horizontal |

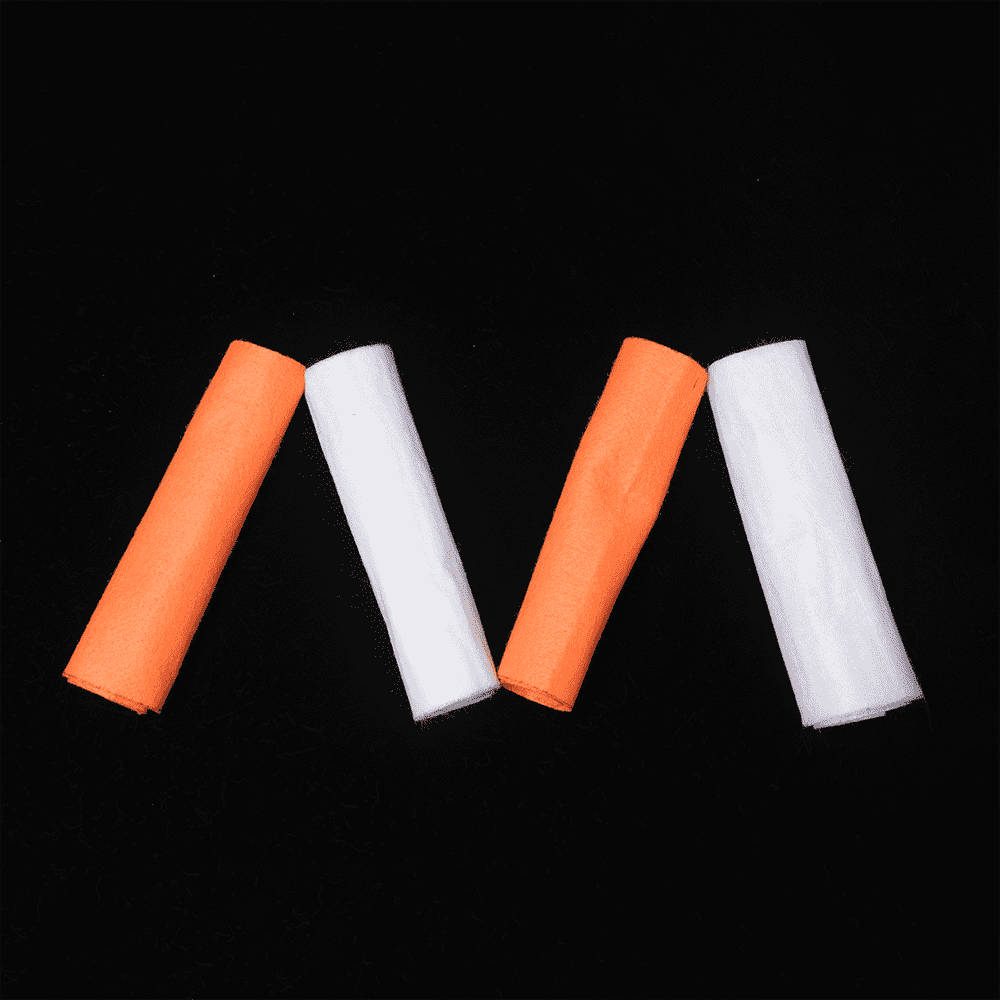

Packing of Top Quality Nonwoven Polypropylene Geotextile Price

You can freely choose PE film or PP woven bag for outer packaging, and there are paper tubes of different sizes inside the product for you to choose freely.

Staple Fiber Needled Non-woven Geotextile Technical Specifications ( GB/T17638-1998) | |||||||||||||

No. | Item | Specifications | Note | ||||||||||

100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 800 | |||

1 | Unit area mass deviation | -8 | -8 | -8 | -8 | -7 | -7 | -7 | -7 | -6 | 6 | -6 |

|

2 | Thickness mm≥ | 0.9 | 1.3 | 1.7 | 2.1 | 2.4 | 2.7 | 3.0 | 3.3 | 3.6 | 4.1 | 5.0 | |

3 | Width deviation | -0.5 | |||||||||||

4 | Breaking strength | 2.5 | 4.5 | 6.5 | 8.0 | 9.5 | 11 | 12.5 | 14.0 | 16.0 | 19.0 | 25.0 | Vertical and horizontal |

5 | Elongation at break % | 20-100 | |||||||||||

6 | CBR bursting strength | 0.3 | 0.6 | 0.8 | 1.2 | 1.4 | 1.8 | 2.1 | 2.4 | 2.7 | 3.2 | 4.0 |

|

7 | Equivalent aperture | 0.07-0.2 |

| ||||||||||

8 | Vertical permeability coefficient | K*(10-1~10-3) | K=1.0-9.9 | ||||||||||

9 | Tear strength | 0.08 | 0.12 | 0.16 | 0.20 | 0.24 | 0.28 | 0.33 | 0.38 | 0.42 | 0.46 | 0.6 | Vertical and horizontal |