PP Woven Geotextile

PP Woven geotextiles-are geosynthetic substances woven from polypropylene and propylene propylene flat yarns. They are broadly used in geotechnical initiatives such as water conservancy, electric power, harbors, roads, and railway constructions.

PP Woven Geotextile

Product Description:

PP woven geotextiles take gain of the advantages of industrialization and low charge of artificial fibers; the traits of excessive strength, low elongation, durability, and corrosion resistance; the traits of secure woven cloth shape and excessive compliance fee of engineering parameters, assembly a differ of geotechnical Requirements for one of a range elements such as filtration, isolation, reinforcement, protection, etc. It is a kind of product with fantastically excessive cost in geotechnical engineering.

In order to make advantageous the steadiness and stability of product structure and the compliance value of engineering parameters, our company's filament woven geotextiles are all produced through wide-width shuttleless looms to make fantastic quality.

PP Woven Geotextile Application:

1) As the reinforcement in the backfill of the preserving wall, or as the panel for anchoring the holding wall. Build wrapped maintaining partitions or abutments.

(2) Strengthen the bendy pavement, restore cracks on the road, and forestall reflection cracks on the pavement.

(3) Increase the steadiness of gravel slope and bolstered soil, forestall soil erosion and freezing harm of soil at low temperature.

(4) The isolation layer between the street ballast and the subgrade, or the isolation layer between the subgrade and the gentle foundation.

(5) Isolation layer between synthetic fill, rockfill or fabric subject and foundation, isolation between exceptional permafrost layers, reverse filtration and reinforcement.

(6) The filter layer of the preliminary upstream dam floor of the ash storage dam or tailings dam, and the filter layer of the drainage device in the backfill soil of the holding wall.

(7) The filter layer round the underground drainage pipe or round the gravel drainage ditch.

(8) The filter layer of water wells, remedy wells or baroclinic pipes in water conservancy projects.

(9) The isolation layer of geotextiles between roads, airports, railway ballast and synthetic rockfill, etc. and the foundation.

(10) Vertical or horizontal drainage inner the earth dam, buried in the soil to dissipate the pore water pressure.

(11) Drainage at the back of the anti-seepage geomembrane in the earth dam or embankment or the decrease phase of the concrete armor.

(12) Eliminate water seepage round the tunnel, decrease the exterior water strain on the lining and seepage around the buildings.

(13) Drainage of artificially stuffed sports activities discipline foundation.

(14) It is used to beef up susceptible foundations in highways (including brief roads), railways, embankments, earth-rock dams, airports, sports activities fields and different projects.

PP Woven Geotextile Features:

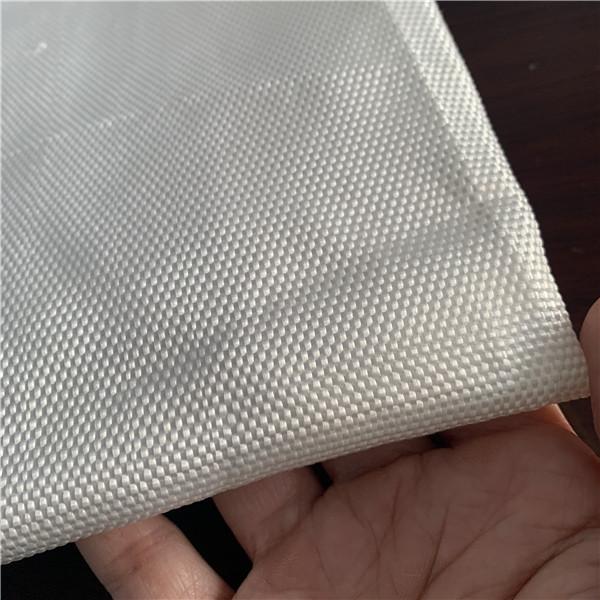

High Strength: Using high-strength industrial polypropylene, polyester, nylon and different artificial fibers as uncooked materials, it has excessive authentic strength. After weaving, it types a normal interweaving structure, and the complete bearing capability is in addition improved.

Durability: The attribute of artificial chemical fiber is that it is no longer effortless to denature, decompose and weather. It can preserve its authentic characteristics for a lengthy time.

Corrosion resistance: Synthetic chemical fibers usually have acid resistance, alkali resistance, insect resistance, and mildew resistance.

Water permeability: Woven fabric can efficaciously manage their structural pores to reap a positive diploma of water permeability.

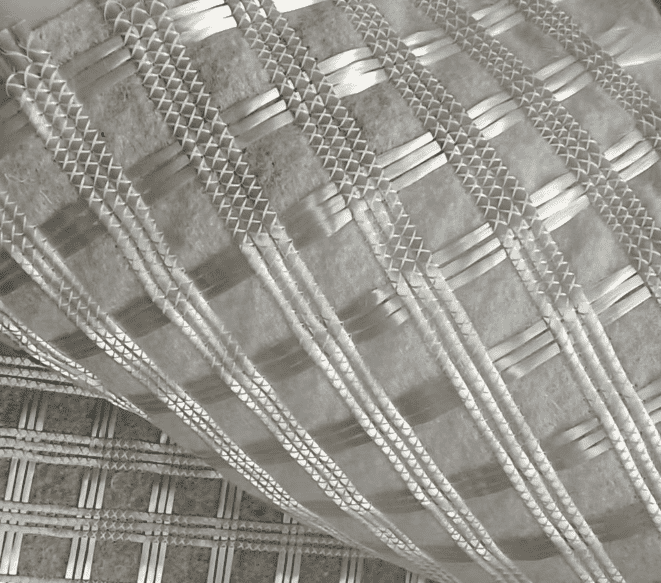

Woven geotextile technical standards:

Product Series | Unit | Allowable Deviation | Woven Geotextile | ||||

ZXF-180 | ZXF-230 | ZXF-260 | ZXF-340 | ZXF-670 | |||

Mass per unit area (single) | G/㎡ | -3% | 180 | 230 | 260 | 340 | 670 |

Tensile strength (longitudinal) | N/5cm | ≥ | 2300 | 2900 | 3300 | 4300 | 10000 |

Elongation (longitudinal) | % | ≤ | 30 | 30 | 30 | 30 | 30 |

Tensile strength (transverse) | N/5cm | ≥ | 1800 | 2350 | 2600 | 3100 | 6000 |

Elongation (transverse) | % | ≤ | 25 | 25 | 27 | 25 | 25 |

Trapezoidal tear strength (longitudinal) | N | ≥ | 850 | 1175 | 1300 | 1500 | 3000 |

Trapezoidal tear strength (transverse) | N | ≥ | 540 | 1107 | 1250 | 1400 | 2800 |

Breaking strength of CBR | N | ≥ | 4700 | 6500 | 7200 | 8000 | 19000 |

Vertical permeability coefficient | Cm/s | ≥ | 2.5*10^ (-3) | 2.3*10^ (-3) | 3* 10^ (-3) | 8*10^ (-3) | 1*10^ (-3) |

Equivalent aperture O95 | mm | ≤ | 0.042 | 0.053 | 0.1 | 0.12 | 0.45 |

Packing of PP Woven Geotextile

You can freely choose PE film or PP woven bag for outer packaging, and there are paper tubes of different sizes inside the product for you to choose freely.

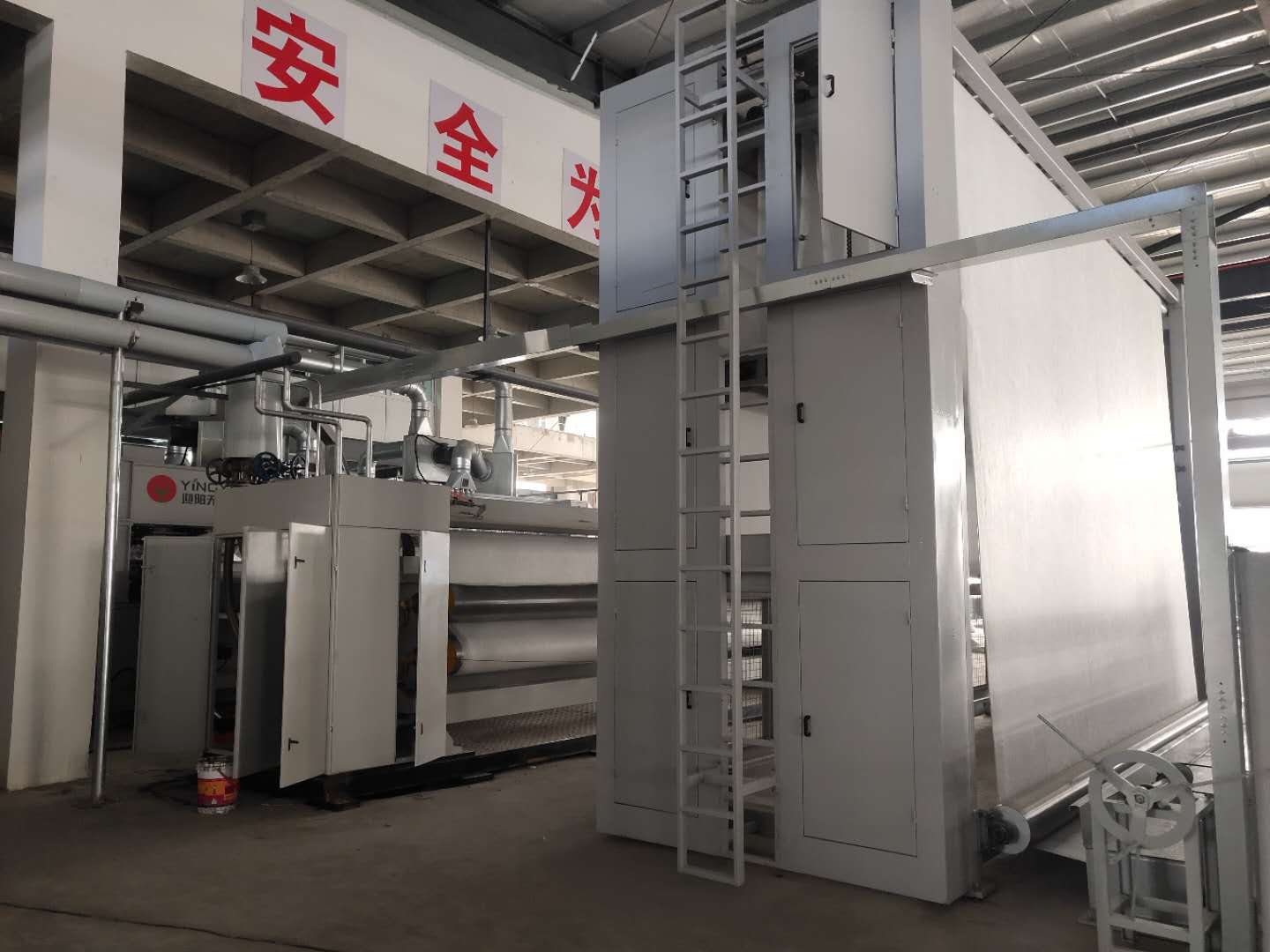

Strength of the company

The organisation has grow to be an necessary processing base of geotechnical substances used in the building of roads, expressways, railways, airports, farmland water conservancy and so on in my country. 30% of the company's merchandise are exported to extra than 20 international locations and areas such as the United States, the United Kingdom, Germany, Canada, Australia, Poland, India, and the Middle East. Over the years, the agency has usually adhered to the company philosophy of "one fit can mild up the sky, and one inch grille can create a world", and operates with integrity.