100g 200g Non-woven Fabric Composite Geotextile

100g 200g Non-woven Fabric composite geotextile-With a width of 6.2 meters, it is the widest composite Geotextile in China. It has excessive puncture resistance, massive friction coefficient, desirable getting older resistance, extensive vary of environmental temperature and tremendous drainage resistance. It is appropriate for water conservancy, chemical engineering, construction, traffic, subway, tunnel, rubbish disposal web site and other initiatives

Material: PET

Color: White

Film thickness: 0.1-1.0mm

Specification: 100g-800g

Length: 50-100m

Certificate: CE/ISO9001

100g 200g Non-woven Fabric Composite Geotextile

Product use;

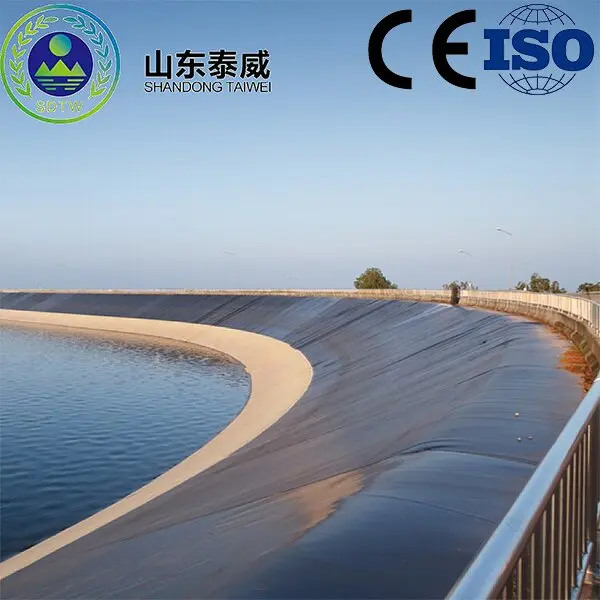

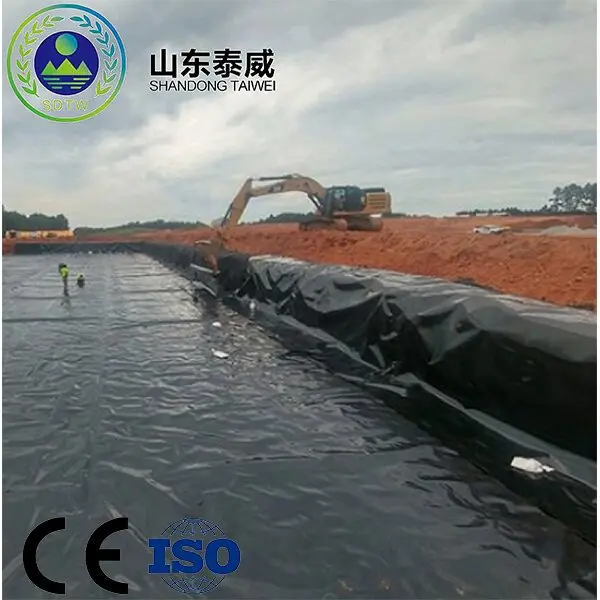

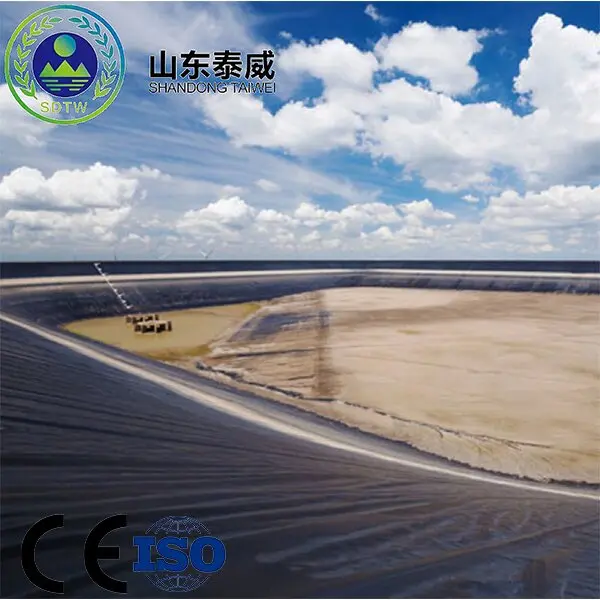

100g 200g Non-woven Fabric Composite Geotextile,Special use for pond Composite Geotextile Function: seepage prevention, isolation use: earth dam, rockfill dam, masonry dam, unfold stress concrete dam; Horizontal anti-seepage cowl in the embankment, dam front, vertical anti-seepage layer as the foundation; Tailings DAMS, sewage reservoirs and reservoir areas; Construction cofferdam; The software of large-scale software program application of river channel and liquid storage pool Composite Geomembrane performs a protecting property in the ecological environment. Can restriction the avenue cost, extend the existence of the carrier, put an give up to the street reflection cracks, tough ground, inconvenient sliding, handy construction, precise sensible impact

Good bodily and mechanical properties

100g 200g Non-woven Fabric Composite Geotextile,Excellent water permeability and warmness resistance composite geotextile, hydraulic dam engineering composite geotextile, seepage proof isolation composite geotextile as the defend layer of geomembrane, so that the tightly guarded closed layer is no longer damaged. In order to forestall UV publicity and enhance anti-aging performance, embedding approach is a correct method. HDPE geomemofilm linings are appropriate for giant purposes requiring UV and ozone resistance, chemical resistance or excessive high-quality installation. Commonly used in landfill and mining applications, the product is delivered in giant rolls 7 meters large and is thermally welded on web page with the aid of educated technicians to furnish a excessive quality, examined licensed installation.Construction suggestion

100g 200g Non-woven Fabric Composite Geotextile,Can restriction the street cost, extend the existence of the carrier, put an cease to the avenue reflection cracks, tough ground, inconvenient sliding, handy construction, right realistic impact Composite Geotextilebroadly talking replaces the widespread fabric gravel layer in the aspect of reverse filtration and drainage. The drainage functionality of the geotextile is at as soon as proportional to the thickness of the geotextile. Generally speaking, the thicker the thickness, the greater the drainage functionality of the geotextile.

Product implementation standards:

| Composite Geotextile Technical Specification | ||||||||||

| Item | Index | |||||||||

| 1 | Nominal breaking strength / ( kN / m ) | 5 | 7.5 | 10 | 12 | 14 | 16 | 18 | 20 | |

| 2 | Longitudinal and transverse rupture strength /( kN / m )≥ | 5.0 | 7.5 | 10 | 12 | 14 | 16 | 18 | 20 | |

| 3 | Vertical and horizontal standard strength corresponding to elongation /% | 30-100 | ||||||||

| 4 | CBR bursting strength /kN ≥ | 1.1 | 1.5 | 1.9 | 2.2 | 2.5 | 2.8 | 3.0 | 3.2 | |

| 5 | Vertical and horizontal tear strength / kN ≥ | 0.15 | 0.25 | 0.32 | 0.40 | 0.48 | 0.56 | 0.62 | 0.70 | |

| 8 | Vertical Permeability Index / ( cm / s) | According customer needs | ||||||||

| 9 | Width deviation /% | -1.0 | ||||||||

| Item | Membrane thickness/mm | |||||||||

| 0.2 | 0.3 | 0.4 | 0.5 | 0.6 | 0.7 | 0.8 | 1.0 | |||

| Hydrostatic pressure resistance / MPa | 1 fabric with 1 membrane | 0.4 | 0.5 | 0.6 | 0.8 | 1.0 | 1.2 | 1.4 | 1.6 | |

| 2 fabric with 1 membrane | 0.5 | 0.6 | 0.8 | 1.0 | 1.2 | 1.4 | 1.6 | 1.8 | ||

Q: How lengthy is your transport time?

A: Generally it is 5-10 days if the items are in stock. Or if the items are no longer in inventory it is 10-15 days, it is based totally on quantity.

Geotextile construction case

1. Use manual rolling, the cloth surface should be flat, and an appropriate allowance for deformation should be left.

2. The installation of long-filament or short-filament geotextiles usually adopts lap joints, stitching and welding. The width of stitching and welding is generally more than 0.1m, and the width of lap joints is generally more than 0.2m. Geotextiles that may be exposed for a long time should be welded or sewn

Geomembrane construction method

Do not drag or drag the geomembrane during transportation to avoid being stabbed by sharp objects.

1. It should extend from the bottom to the high position, do not pull it too tightly, and leave a margin of 1.50% for partial sinking and stretching. Considering the actual situation of this project, the slope shall be paved from top to bottom;

2. The longitudinal joints of two adjacent panels should not be on a horizontal line, and should be staggered by more than 1m;

3. The longitudinal joint should be more than 1.50m away from the dam foot and the bend foot, and should be located on a plane;

4. First the side slope and then the bottom of the field;

5. When laying the side slope, the film spreading direction should be basically parallel to the maximum slope line.

| Composite Geomembrane Technical Specification | ||||||||||

| Item | Index | |||||||||

| 1 | Nominal breaking strength / ( kN / m ) | 5 | 7.5 | 10 | 12 | 14 | 16 | 18 | 20 | |

| 2 | Longitudinal and transverse rupture strength /( kN / m )≥ | 5.0 | 7.5 | 10 | 12 | 14 | 16 | 18 | 20 | |

| 3 | Vertical and horizontal standard strength corresponding to elongation /% | 30-100 | ||||||||

| 4 | CBR bursting strength /kN ≥ | 1.1 | 1.5 | 1.9 | 2.2 | 2.5 | 2.8 | 3.0 | 3.2 | |

| 5 | Vertical and horizontal tear strength / kN ≥ | 0.15 | 0.25 | 0.32 | 0.40 | 0.48 | 0.56 | 0.62 | 0.70 | |

| 8 | Vertical Permeability Index / ( cm / s) | According customer needs | ||||||||

| 9 | Width deviation /% | -1.0 | ||||||||

| Item | Membrane thickness/mm | |||||||||

| 0.2 | 0.3 | 0.4 | 0.5 | 0.6 | 0.7 | 0.8 | 1.0 | |||

| Hydrostatic pressure resistance / MPa | 1 fabric with 1 membrane | 0.4 | 0.5 | 0.6 | 0.8 | 1.0 | 1.2 | 1.4 | 1.6 | |

| 2 fabric with 1 membrane | 0.5 | 0.6 | 0.8 | 1.0 | 1.2 | 1.4 | 1.6 | 1.8 | ||

| Composite Geomembrane Technical Specification | ||||||||||

| Item | Index | |||||||||

| 1 | Nominal breaking strength / ( kN / m ) | 5 | 7.5 | 10 | 12 | 14 | 16 | 18 | 20 | |

| 2 | Longitudinal and transverse rupture strength /( kN / m )≥ | 5.0 | 7.5 | 10 | 12 | 14 | 16 | 18 | 20 | |

| 3 | Vertical and horizontal standard strength corresponding to elongation /% | 30-100 | ||||||||

| 4 | CBR bursting strength /kN ≥ | 1.1 | 1.5 | 1.9 | 2.2 | 2.5 | 2.8 | 3.0 | 3.2 | |

| 5 | Vertical and horizontal tear strength / kN ≥ | 0.15 | 0.25 | 0.32 | 0.40 | 0.48 | 0.56 | 0.62 | 0.70 | |

| 8 | Vertical Permeability Index / ( cm / s) | According customer needs | ||||||||

| 9 | Width deviation /% | -1.0 | ||||||||

| Item | Membrane thickness/mm | |||||||||

| 0.2 | 0.3 | 0.4 | 0.5 | 0.6 | 0.7 | 0.8 | 1.0 | |||

| Hydrostatic pressure resistance / MPa | 1 fabric with 1 membrane | 0.4 | 0.5 | 0.6 | 0.8 | 1.0 | 1.2 | 1.4 | 1.6 | |

| 2 fabric with 1 membrane | 0.5 | 0.6 | 0.8 | 1.0 | 1.2 | 1.4 | 1.6 | 1.8 | ||