PET Composite Geotextile

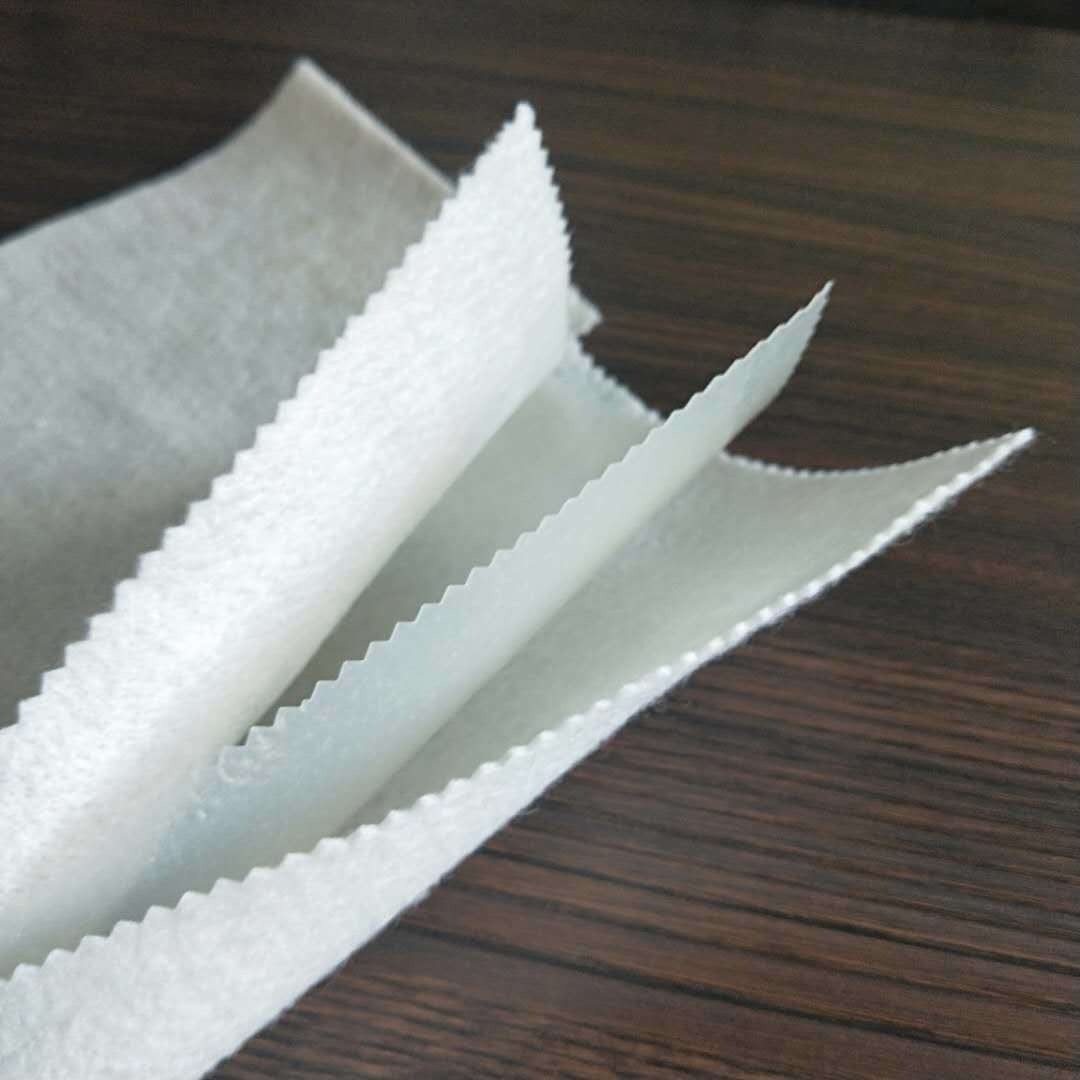

PET composite geotextile-Non-woven geotextile is used as the substrate, and polyethylene, polyvinyl chloride and different substances are used asthe membrane. The composite Geotextile of the non-woven fabric, has one cloth with one membrane,two material with one membrane, two menbrane with one material ect.

Material: PET

Color: White

Film thickness: 0.1-1.0mm

Specification: 100g-800g

Length: 50-100m

Certificate: CE/ISO9001

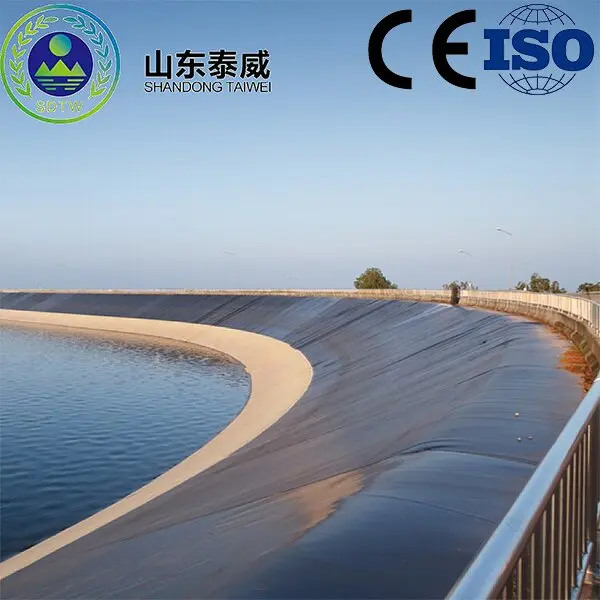

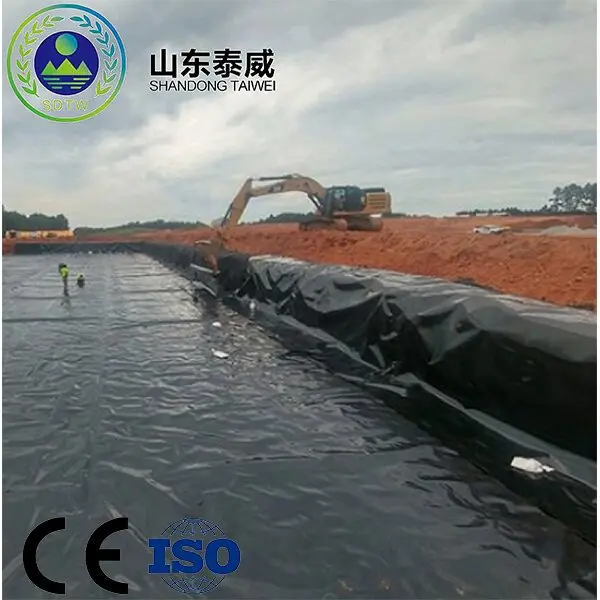

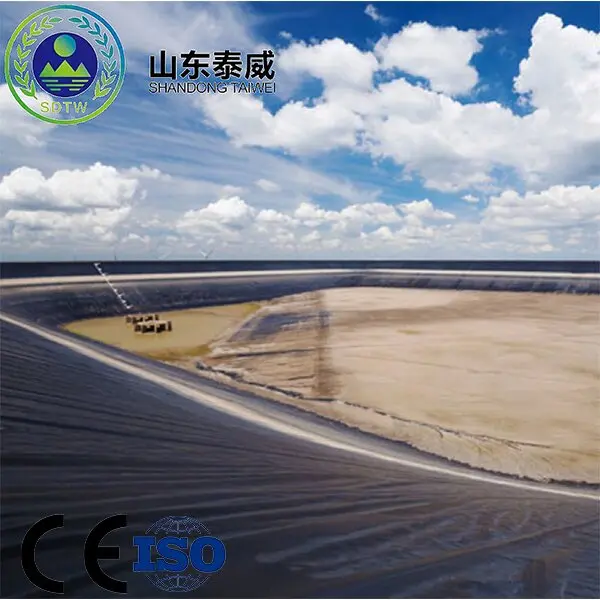

Scope of application:

PET Composite Geotextile is an ideal impervious material, suitable for channel, drainage, guard, plain reservoir impervious reinforcement and rockfill dam and other water conservancy and traffic tunnel applications

Good physical and mechanical properties

The working environment of composite geotextile is harsh, in many cases it is soaked in water or spread in soil with high humidity, so it must have good hydrolysis resistance and wet mechanical properties.

Resistance to ultraviolet radiation, hydrolysis, high and low temperature

Composite geotextile should be exposed to sunlight, so it should have corresponding UV resistance. Composite geotextile needs high melting point to adapt to the temperature of contact with asphalt and other materials.

Product implementation standards:

| Composite Geotextile Technical Specification | ||||||||||

| Item | Index | |||||||||

| 1 | Nominal breaking strength / ( kN / m ) | 5 | 7.5 | 10 | 12 | 14 | 16 | 18 | 20 | |

| 2 | Longitudinal and transverse rupture strength /( kN / m )≥ | 5.0 | 7.5 | 10 | 12 | 14 | 16 | 18 | 20 | |

| 3 | Vertical and horizontal standard strength corresponding to elongation /% | 30-100 | ||||||||

| 4 | CBR bursting strength /kN ≥ | 1.1 | 1.5 | 1.9 | 2.2 | 2.5 | 2.8 | 3.0 | 3.2 | |

| 5 | Vertical and horizontal tear strength / kN ≥ | 0.15 | 0.25 | 0.32 | 0.40 | 0.48 | 0.56 | 0.62 | 0.70 | |

| 8 | Vertical Permeability Index / ( cm / s) | According customer needs | ||||||||

| 9 | Width deviation /% | -1.0 | ||||||||

| Item | Membrane thickness/mm | |||||||||

| 0.2 | 0.3 | 0.4 | 0.5 | 0.6 | 0.7 | 0.8 | 1.0 | |||

| Hydrostatic pressure resistance / MPa | 1 fabric with 1 membrane | 0.4 | 0.5 | 0.6 | 0.8 | 1.0 | 1.2 | 1.4 | 1.6 | |

| 2 fabric with 1 membrane | 0.5 | 0.6 | 0.8 | 1.0 | 1.2 | 1.4 | 1.6 | 1.8 | ||

Packing of PET Composite Geotextile

You can freely choose PE film or PP woven bag for outer packaging, and there are paper tubes of different sizes inside the product for you to choose freely.

Geotextiles draw close the following three points:

Look at the defects. Knitted polyester fabric have many look defects, and serious defects will have an effect on the sporting effect. Such as leak needle holes, lacking wires, hooked wires, damaged ends, wire anxiety and serious weft skew, etc. Lighter defects, such as chromatic aberration, curling, horrific edges, splicing, knots, coloured flowers, reflections, oil-colored silk, thick and skinny silk, etc. Although the material with mild defects can be worn, it will have an effect on the grade of the fabric.

| Composite Geomembrane Technical Specification | ||||||||||

| Item | Index | |||||||||

| 1 | Nominal breaking strength / ( kN / m ) | 5 | 7.5 | 10 | 12 | 14 | 16 | 18 | 20 | |

| 2 | Longitudinal and transverse rupture strength /( kN / m )≥ | 5.0 | 7.5 | 10 | 12 | 14 | 16 | 18 | 20 | |

| 3 | Vertical and horizontal standard strength corresponding to elongation /% | 30-100 | ||||||||

| 4 | CBR bursting strength /kN ≥ | 1.1 | 1.5 | 1.9 | 2.2 | 2.5 | 2.8 | 3.0 | 3.2 | |

| 5 | Vertical and horizontal tear strength / kN ≥ | 0.15 | 0.25 | 0.32 | 0.40 | 0.48 | 0.56 | 0.62 | 0.70 | |

| 8 | Vertical Permeability Index / ( cm / s) | According customer needs | ||||||||

| 9 | Width deviation /% | -1.0 | ||||||||

| Item | Membrane thickness/mm | |||||||||

| 0.2 | 0.3 | 0.4 | 0.5 | 0.6 | 0.7 | 0.8 | 1.0 | |||

| Hydrostatic pressure resistance / MPa | 1 fabric with 1 membrane | 0.4 | 0.5 | 0.6 | 0.8 | 1.0 | 1.2 | 1.4 | 1.6 | |

| 2 fabric with 1 membrane | 0.5 | 0.6 | 0.8 | 1.0 | 1.2 | 1.4 | 1.6 | 1.8 | ||

| Composite Geomembrane Technical Specification | ||||||||||

| Item | Index | |||||||||

| 1 | Nominal breaking strength / ( kN / m ) | 5 | 7.5 | 10 | 12 | 14 | 16 | 18 | 20 | |

| 2 | Longitudinal and transverse rupture strength /( kN / m )≥ | 5.0 | 7.5 | 10 | 12 | 14 | 16 | 18 | 20 | |

| 3 | Vertical and horizontal standard strength corresponding to elongation /% | 30-100 | ||||||||

| 4 | CBR bursting strength /kN ≥ | 1.1 | 1.5 | 1.9 | 2.2 | 2.5 | 2.8 | 3.0 | 3.2 | |

| 5 | Vertical and horizontal tear strength / kN ≥ | 0.15 | 0.25 | 0.32 | 0.40 | 0.48 | 0.56 | 0.62 | 0.70 | |

| 8 | Vertical Permeability Index / ( cm / s) | According customer needs | ||||||||

| 9 | Width deviation /% | -1.0 | ||||||||

| Item | Membrane thickness/mm | |||||||||

| 0.2 | 0.3 | 0.4 | 0.5 | 0.6 | 0.7 | 0.8 | 1.0 | |||

| Hydrostatic pressure resistance / MPa | 1 fabric with 1 membrane | 0.4 | 0.5 | 0.6 | 0.8 | 1.0 | 1.2 | 1.4 | 1.6 | |

| 2 fabric with 1 membrane | 0.5 | 0.6 | 0.8 | 1.0 | 1.2 | 1.4 | 1.6 | 1.8 | ||