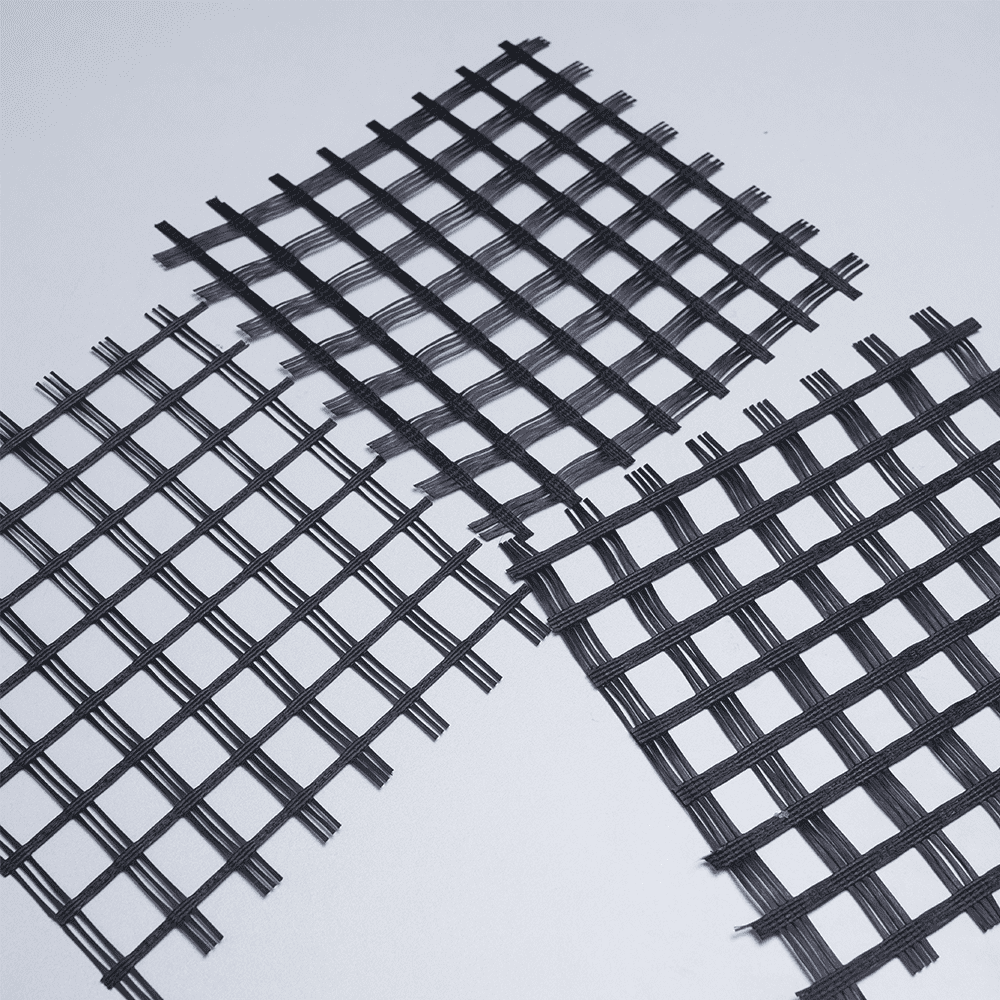

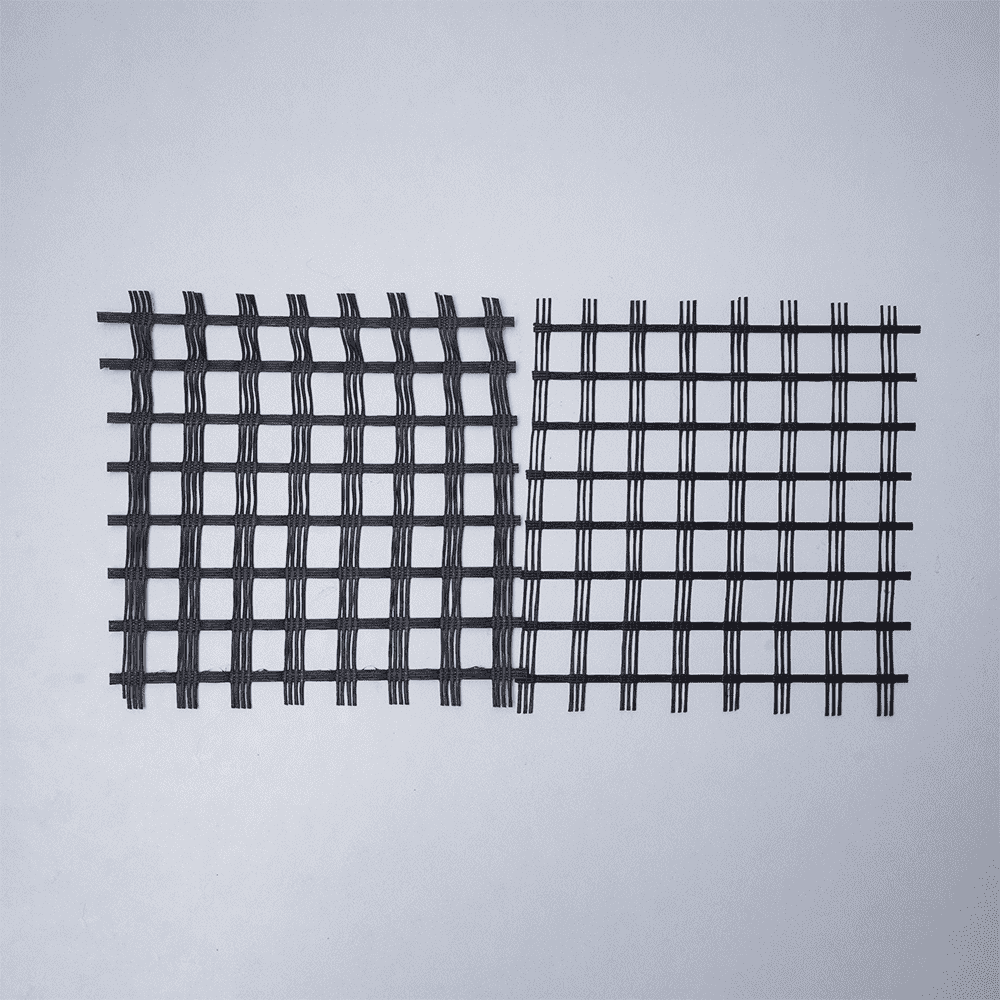

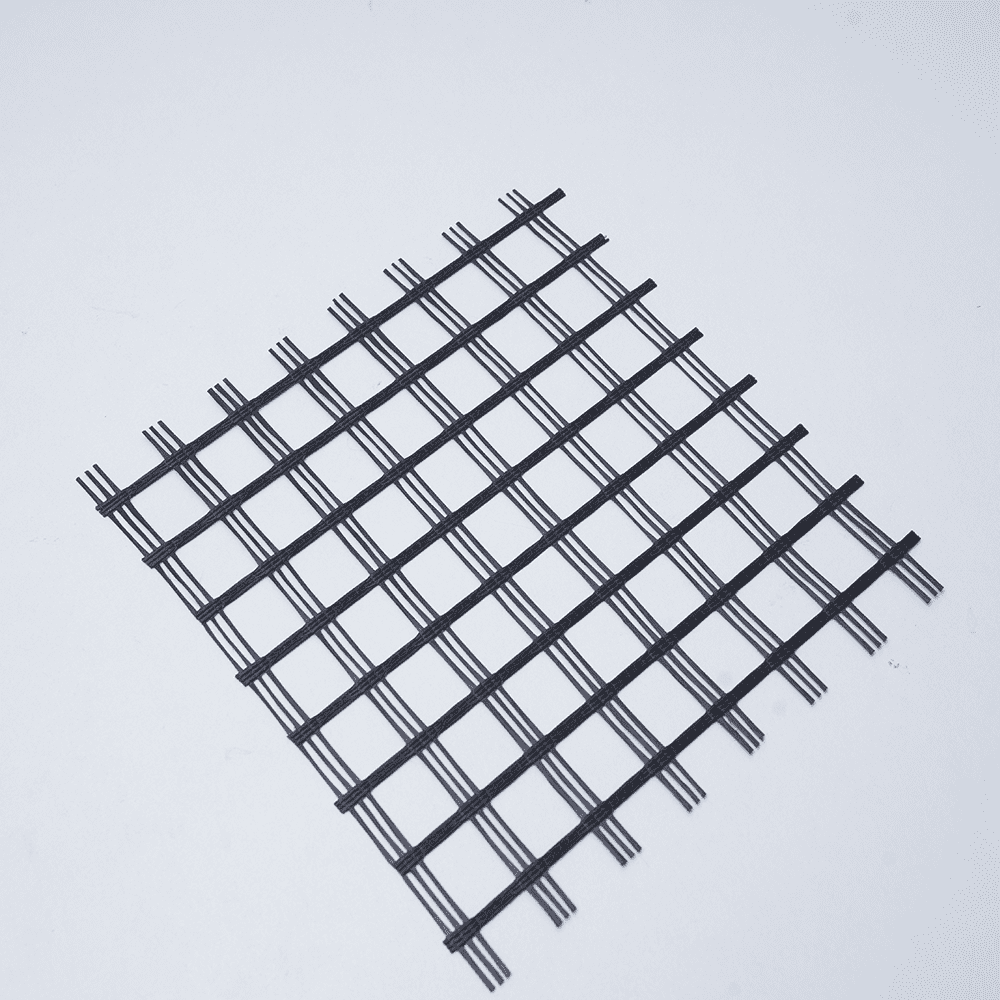

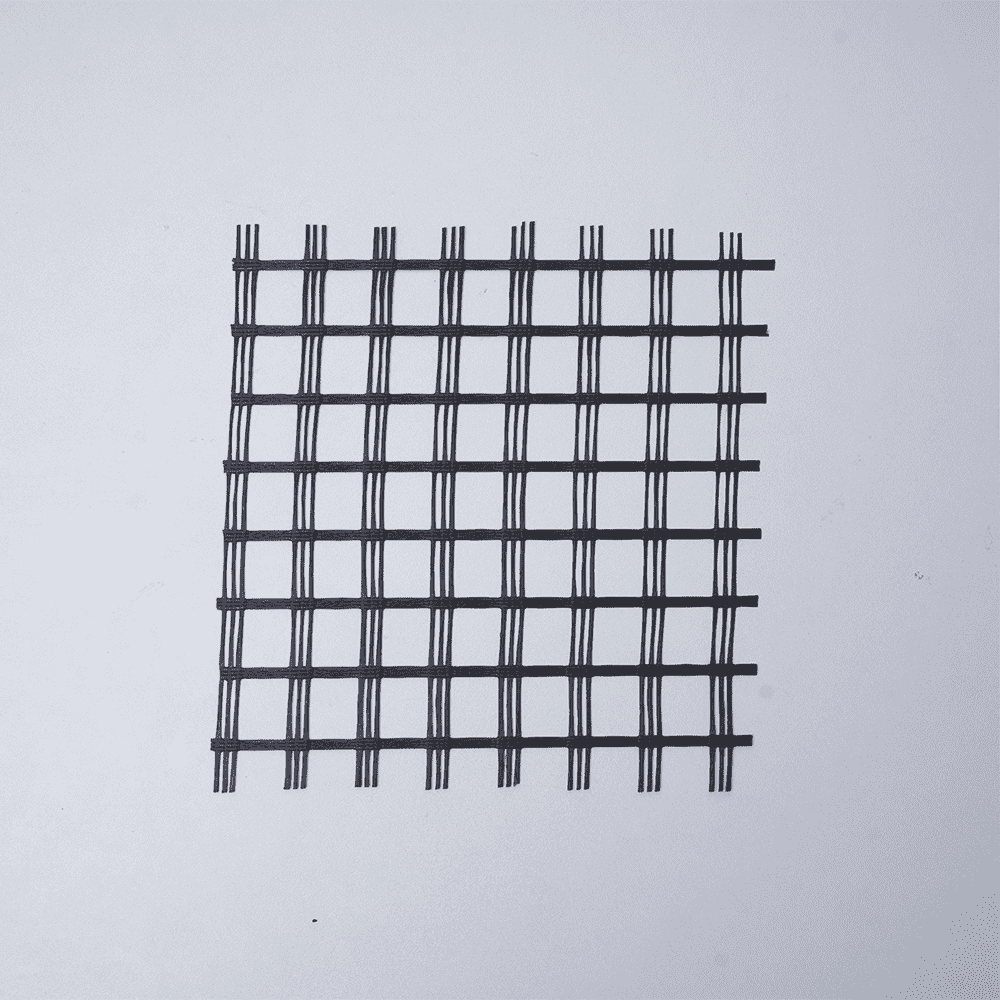

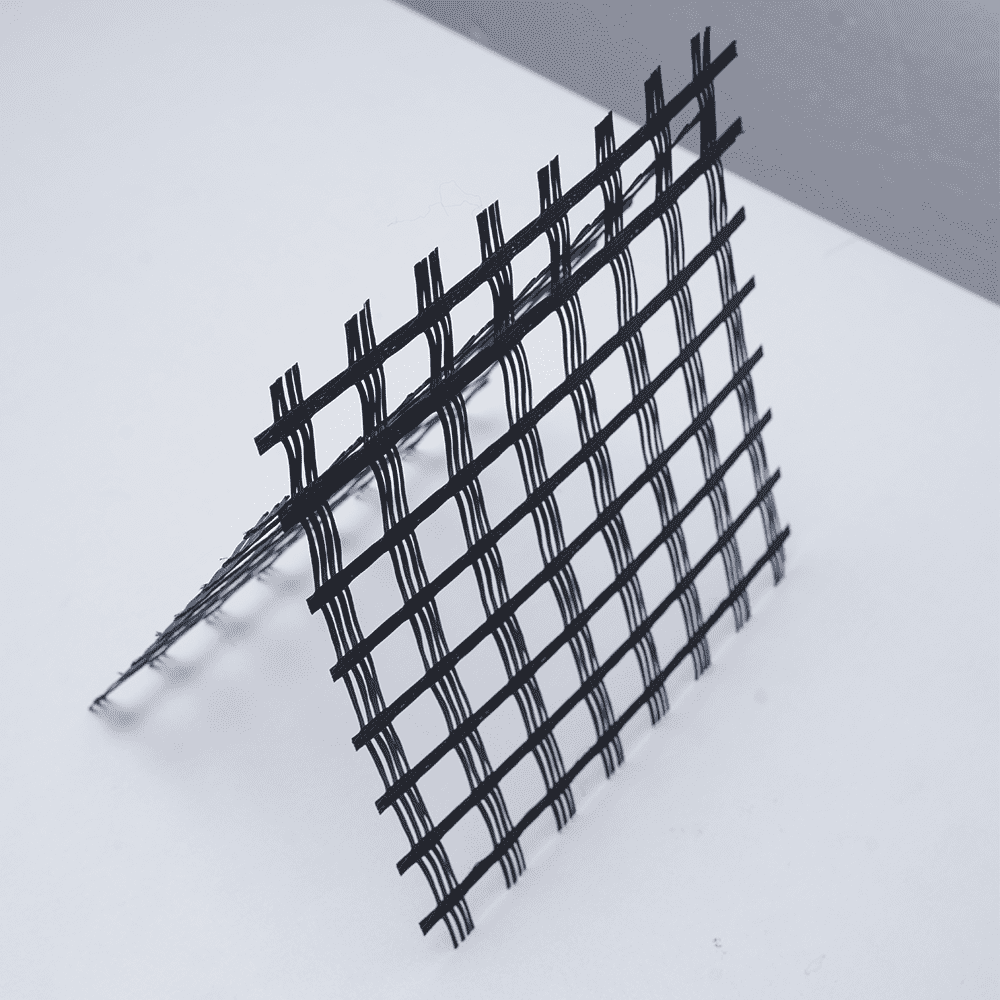

Subgrade grid fiberglass geogrid

Geogrids are divided into

1.There are four major categories of plastic geogrids, steel plastic geogrids, glass fiber geogrids, and polyester warp knitted polyester geogrids.

2.Grille is a two-dimensional grid or three-dimensional grid with a certain height formed by thermoplastic or molded high polymer materials such as polypropylene and polyvinyl chloride.

Geotechnical materials for road construction reinforcement Geogrid Mesh

Product Introduction: Fiberglass Geogrid:

The Fiberglass Geogrid is a high-performance reinforcement material used in the construction of retaining walls, roads, railways, embankments, and various other geotechnical applications. Made from high-quality fiberglass yarns, this geogrid offers exceptional strength, durability, and long-lasting performance.

Features:

High Tensile Strength: The fiberglass geogrid has a high tensile strength, providing excellent reinforcement and load-bearing capacity to soil structures. It effectively redistributes the applied loads, minimizing deformation and enhancing stability.

Chemical Resistance: This geogrid is resistant to chemicals, acids, and alkalis, making it suitable for use in harsh environments. It ensures long-term stability and integrity even in chemically aggressive soils.

Aging Resistance: The fiberglass material has excellent resistance to aging and deterioration caused by UV radiation, moisture, and temperature variations. The geogrid maintains its properties over time, ensuring long-term performance.

Easy Installation: The geogrid is lightweight and easily transportable, making it convenient to handle and install. It can be cut and trimmed to fit specific project requirements, providing flexibility and ease of use.

Cost-effective: The use of the fiberglass geogrid can significantly reduce the required excavation depth and the need for traditional construction materials, resulting in cost savings. It also enhances the overall lifespan and performance of the structure, reducing maintenance and repair costs.

Versatile Applications: The fiberglass geogrid is suitable for a wide range of geotechnical applications, such as slope stabilization, reinforcement of soft soils, soil erosion control, and ground stabilization. It is also used in the construction of roads, railways, airport runways, and retaining walls.

Application :

Glass fiber geogrid is a kind of excellent geosynthetic material used for pavement reinforcement, old road reinforcement, reinforcing roadbed and soft soil base. Glass fiber geogrid can be used for various highways, railroads, airports, roadbed reinforcement, pavement reinforcement, large parking lots and dock yards to carry the foundation enhancement, railroads, highways, slope protection, culvert enhancement, unidirectional tensile geogrid enhancement of soil slopes after the second enhancement, further enhancement of soil slopes, to prevent soil erosion, mines, pits, reinforcement of the old asphalt concrete pavement reinforcement enhancement of asphalt surface layer, prevention and control of disease, concrete pavement reconstruction of composite pavement and other projects. concrete pavement reconstruction of composite pavement and other projects.

Fiberglass Geogrid Technical Specification | |||||||

Item | Specification | ||||||

EGA 30-30 | EGA 40-40 | EGA 50-50 | EGA 80-80 | EGA 100-100 | EGA 125-125 | EGA 150-150 | |

Mesh size | 12.7×12.7~25.4×25.4 | ||||||

Tensile strength | ≥30 | ≥40 | ≥50 | ≥80 | ≥100 | ≥125 | ≥150 |

Tensile strength at 5% elongation KN/m≥ | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 |

Temperature resistance | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 |

Width (m) | 1~3 | ||||||

Packing of Fiberglass Geogrid Technical Specification

One-way Stretch Plastic Geogrid GB/T17689-1999 | |||||||||||||

Item | Specification | ||||||||||||

TGDG25 | TGDG35 | TGDG50 | TGDG80 | TGDG110 | TGDG150 | TGDG170 | TGDG200 | TGDG220 | TGDG240 | TGDG260 | TGDG280 | TGDG300 | |

Tensile strength KN/m≥ | 25 | 35 | 50 | 80 | 110 | 150 | 170 | 200 | 220 | 240 | 260 | 280 | 300 |

Standard elongation %≤ | 10.0 | ||||||||||||

Tensile strength at 2% elongation KN/m≥ | 6 | 10 | 12 | 26 | 30 | 39 | 45 | 56 | 59 | 65 | 78 | 84.5 | 90 |

Tensile strength at 5% elongation KN/m≥ | 12 | 22 | 28 | 48 | 60 | 77 | 90 | 112 | 120 | 132 | 157 | 170 | 182 |

Creep Ultimate Strength KN/m≥ | 11 | 15 | 21 | 30.2 | 41 | 49 | 57 | 64 | 71.5 | 79 | 86 | 91.5 | 100 |

Width (m) | 1~3 | ||||||||||||