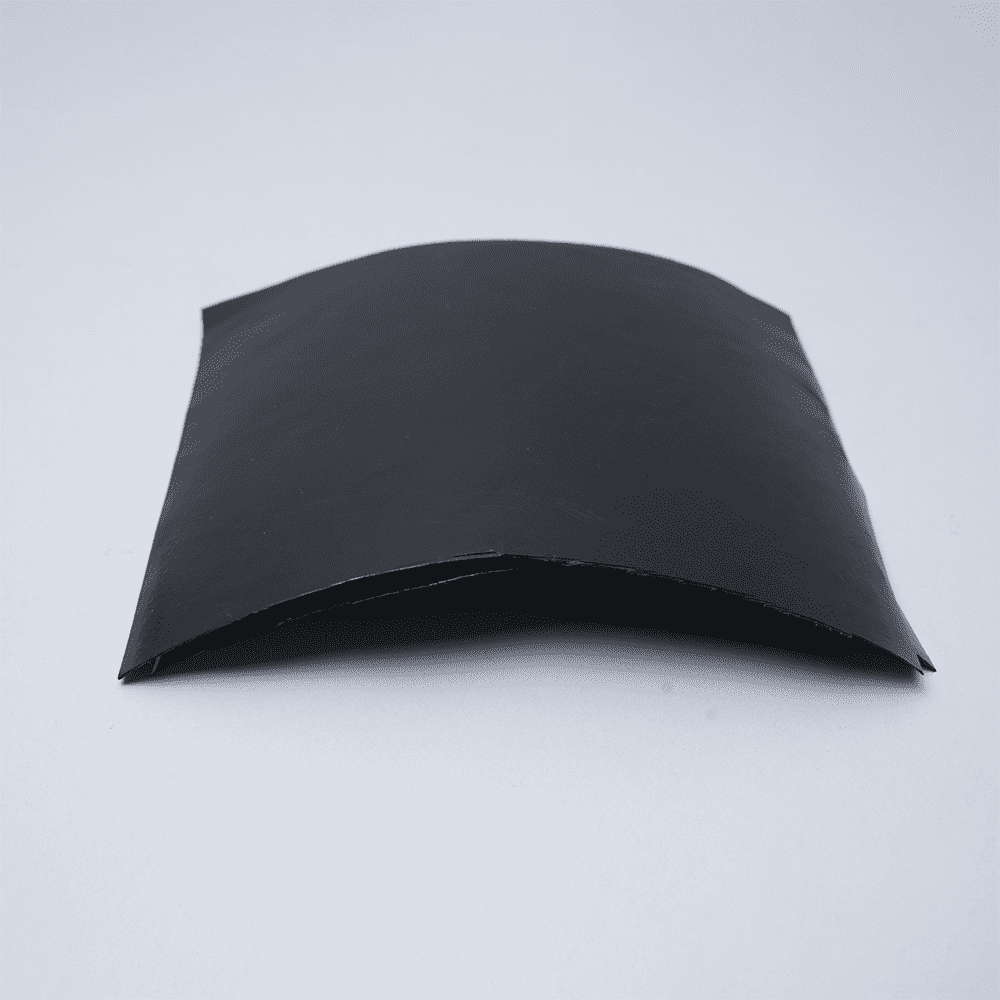

Dam liner HDPE geomembrane

HDPE geomembrane ;

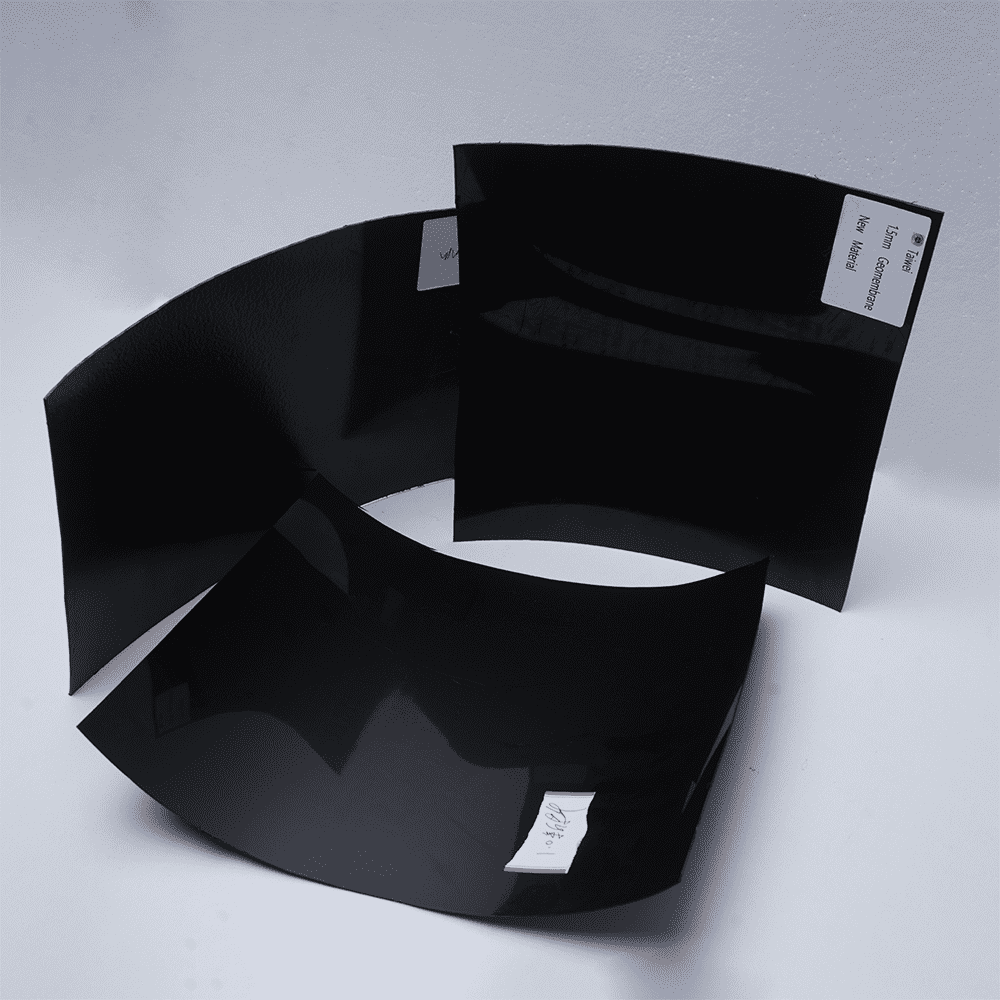

Product specifications; Thickness; 0.5-2.0mm, width 4-8 meters, helps customization

Product characteristics; HDPE geomembrane has proper resistance to environmental stress cracking, big company temperature (-60-+60), and prolonged service existence (50 years)

Application scope; Merit in water conservancy, aquaculture, fish ponds, and so forth

Road construction HDPE Geomembrane

Product Introduction:

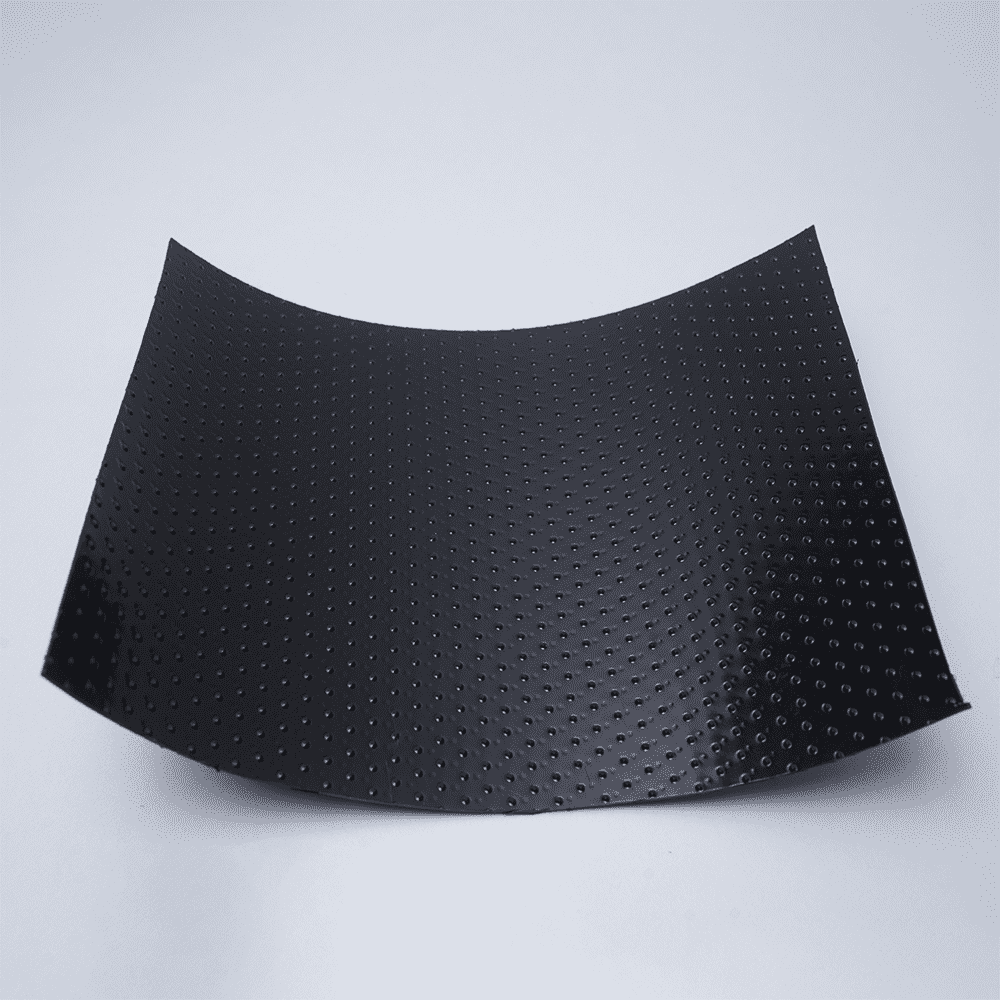

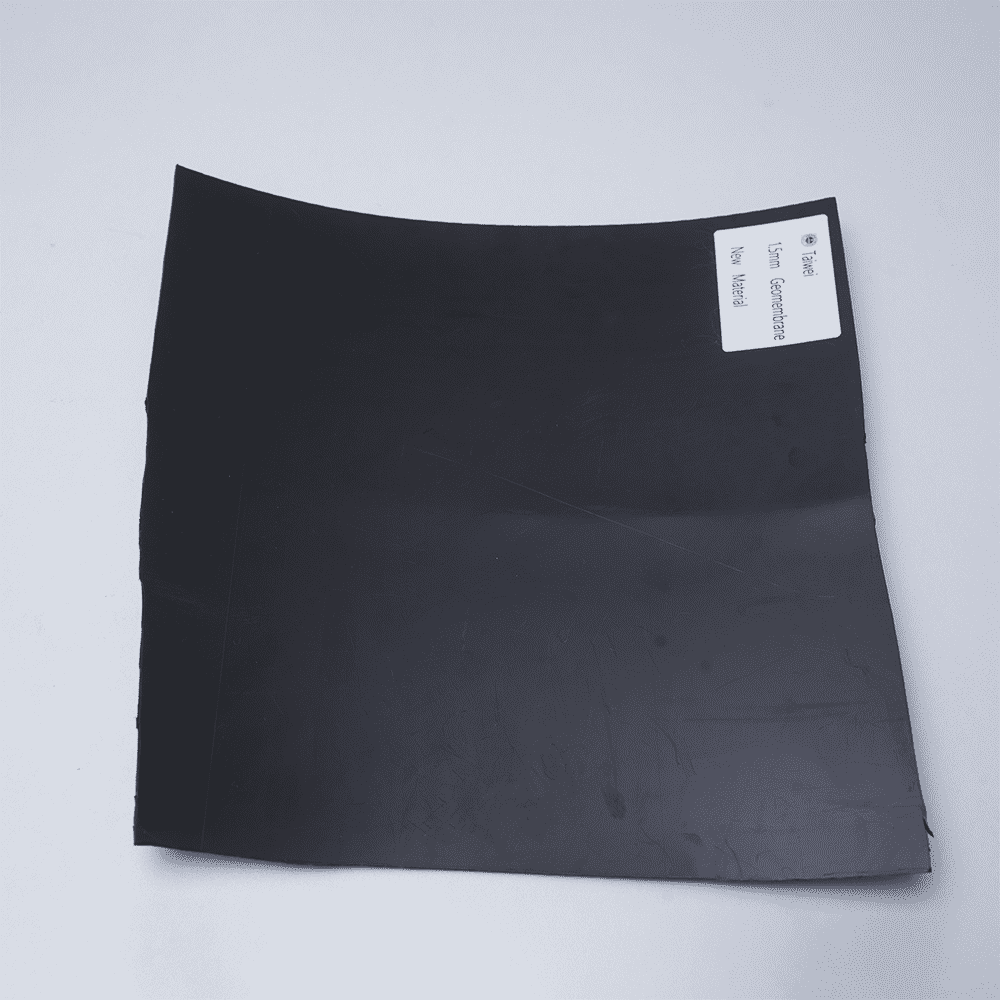

The HDPE Geomembrane is a high-density polyethylene liner designed to provide an impermeable barrier in various geotechnical applications. Manufactured using state-of-the-art technology, it offers excellent chemical resistance, mechanical properties, and environmental durability.

Features:

Impermeable Barrier: The HDPE geomembrane effectively prevents the migration of liquids, gases, and contaminants by creating a robust impermeable layer.

Chemical Resistance: It showcases excellent resistance to a wide range of chemicals, including acids, alkalis, and organic solvents. This feature makes it an ideal choice for applications involving liquid containment.

Outstanding Durability: The HDPE geomembrane is engineered to withstand harsh environmental conditions, including exposure to UV radiation, weathering, and thermal stress. It maintains its performance properties over an extended service life.

Flexibility: It exhibits exceptional flexibility, allowing it to adapt to irregular surfaces and accommodate ground movements without compromising its integrity.

Ease of Installation: The HDPE geomembrane comes in roll form, which makes it easy to handle and install. This feature ensures a quick and efficient installation process, reducing project time and labor costs.

Application:

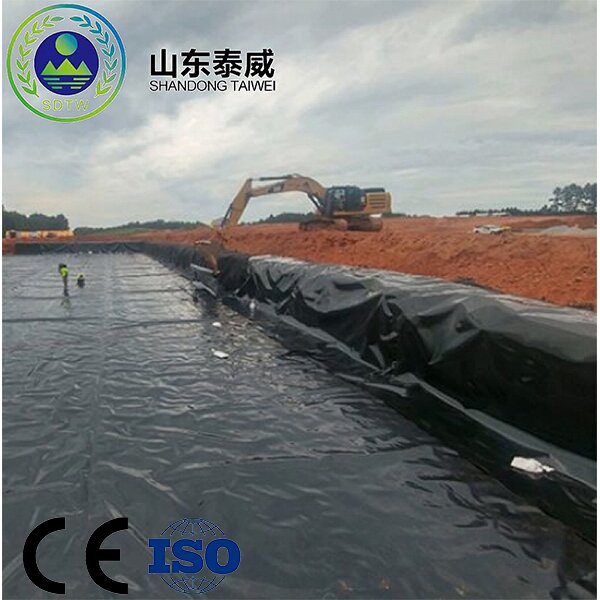

Landfills: HDPE geomembranes are widely used as landfill liners. Their superior chemical resistance and impermeability contribute to effective waste containment, preventing the contamination of soil and groundwater.

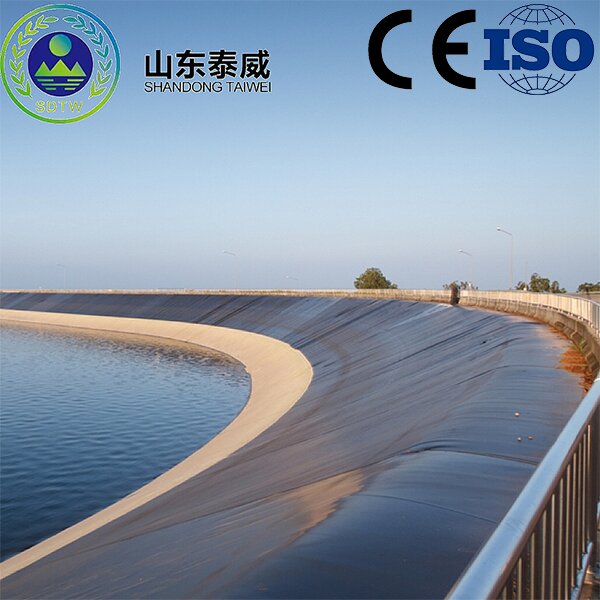

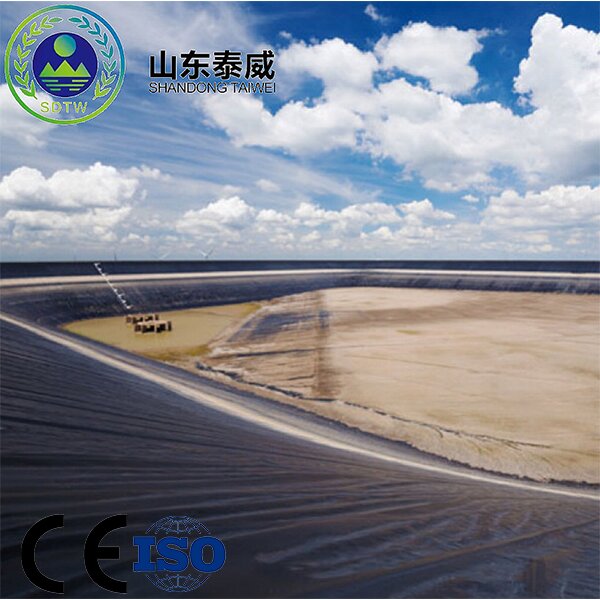

Pond and Canal Liners: Due to their impermeability, HDPE geomembranes are suitable for lining ponds, lakes, reservoirs, and canals. They prevent seepage, promote efficient water storage, and protect against water loss.

Mining and Environmental Protection: These geomembranes are used in mining operations as liners for tailings ponds, ensuring that hazardous liquids are safely contained without polluting surrounding areas. They are also used in environmental protection projects, such as groundwater and soil remediation.

Agriculture and Aquaculture: HDPE geomembranes are used in agriculture for lining irrigation channels, preventing water loss due to seepage. They are also widely employed in aquaculture for pond liners, preventing water contamination and ensuring a healthy environment for fish and other aquatic species.

Product Implementation Standards: America GRI GM-13 Standard

HDPE Geomembrane Technical Parameter (GRI GM13 ASTM Standard) | ||||||||

Spec Properties | Test | GMS0.5 | GMS0.75 | GMS1.0 | GMS1.25 | GMS1.5 | GMS2.0 | GMS2.5 |

Thickness | D5199 | 0.5mm | 0.75mm | 1.00mm | 1 .25mm | 1.50mm | 2.00mm | 2.50mm |

Density (≥ g/cc) | D1505 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 |

Tensile Properties | D6693 Type IV | 8 kN/m 14 kN/m 12% 700% | 11 kN/m | 15 kN/m | 18 kN/m | 22 kN/m 40 kN/m 12% 700% | 29kN/m 53 KN/m 12% 700% | 37kN/m 67kN/m 12% 700% |

Tear Resistance (≥) | D 1004 | 64N | 93N | 125 N | 156N | 187N | 249 N | 311 N |

Puncture Resistance(≥) | D 4833 | 160N | 240N | 320 N | 400 N | 480N | 640 N | 800 N |

Stress Crack Resistance (≥) | D 5397 | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr |

Carbon Black Content | D 1603 | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% |

Carbon Black Dispersion | D 5596 | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) |

Oxidative Induction Time(OIT)(≥) (a)Standard OIT ——or—— | D 3895 D 5885 | 100 min | 100 min | 100 min | 100 min | 100 min | 100 min | 100 min |

Packing of High Quality Good anti-seepage performance HDPE geomembrane

Equipment of High Quality Good anti-seepage performance HDPE geomembrane

Usage Scenarios of High Quality Good anti-seepage performance HDPE geomembrane

HDPE Geomembrane Technical Parameter (GRI GM13 ASTM Standard) | ||||||||

Spec Properties | Test | GMS0.5 | GMS0.75 | GMS1.0 | GMS1.25 | GMS1.5 | GMS2.0 | GMS2.5 |

Thickness | D5199 | 0.5mm | 0.75mm | 1.00mm | 1 .25mm | 1.50mm | 2.00mm | 2.50mm |

Density (≥ g/cc) | D1505 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 |

Tensile Properties | D6693 Type IV | 8 kN/m 14 kN/m 12% 700% | 11 kN/m | 15 kN/m | 18 kN/m | 22 kN/m 40 kN/m 12% 700% | 29kN/m 53 KN/m 12% 700% | 37kN/m 67kN/m 12% 700% |

Tear Resistance (≥) | D 1004 | 64N | 93N | 125 N | 156N | 187N | 249 N | 311 N |

Puncture Resistance(≥) | D 4833 | 160N | 240N | 320 N | 400 N | 480N | 640 N | 800 N |

Stress Crack Resistance (≥) | D 5397 | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr |

Carbon Black Content | D 1603 | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% |

Carbon Black Dispersion | D 5596 | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) |

Oxidative Induction Time(OIT)(≥) (a)Standard OIT ——or—— | D 3895 D 5885 | 100 min | 100 min | 100 min | 100 min | 100 min | 100 min | 100 min |

Related Products

Submitted successfully

We will contact you as soon as possible

Submitted successfully

We will contact you as soon as possible