Good anti-seepage performance HDPE geomembrane

Good anti-seepage performance HDPE geomembrane - The common overall performance is stable, and the anti-corrosion normal overall performance is enormously good, which will enlarge the company life, and this geomembrane is moreover on hand for transportation and construction, which without a doubt will extend its economic benefits.

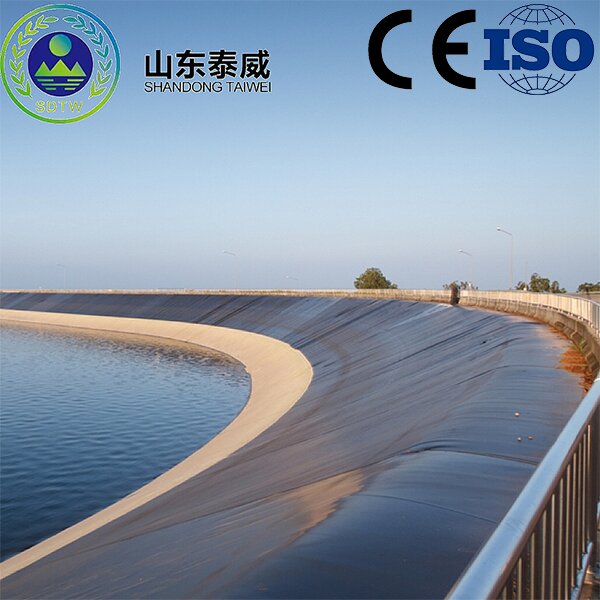

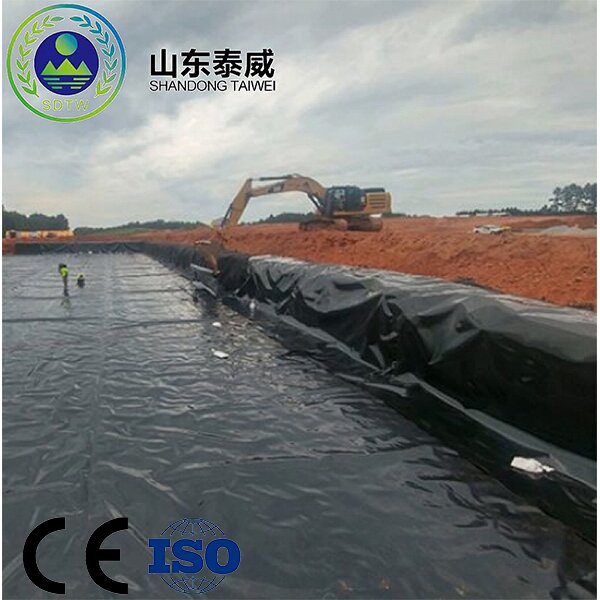

Single hard ground geomembrane is drastically used in: HDPE geomembrane for anti-seepage (special) of landfill; HDPE geomembrane for anti-seepage (special) of sewage remedy plant; HDPE geomembrane for anti-seepage (special) of strength plant tailings treatment; HDPE geomembrane for chemical plant, fertilizer plant, sugar manufacturing facility sewage tailings treatment (special); HDPE geomembrane for non-ferrous metallurgy, sulfuric acid pool, tailings therapy (special). Subway, basement, tunnel, roof lining anti-seepage. Horizontal anti-seepage laying and vertical anti-seepage laying of reservoirs, canals, and dams. Sea water, smooth water, farm seepage prevention.

Good anti-seepage performance HDPE geomembrane

Geomembrane is a geotechnical anti-seepage fabric composed of plastic film as the anti-seepage base fabric and non-woven fabric. The anti-seepage usual overall performance of the new fabric geomembrane essentially depends upon on the anti-seepage universal overall performance of the plastic film. The plastic movies used for anti-seepage at home and distant places particularly consist of polyvinyl chloride (PVC), polyethylene (PE), EVA (ethylene/vinyl acetate copolymer), and ECB (ethylene vinyl acetate modified asphalt copolymer) is moreover designed for tunnel applications. They are polymer chemical flexible components with small particular gravity, sturdy extensibility, immoderate adaptability to deformation, corrosion resistance, low temperature resistance, and exceptional frost resistance.

Product specification:

Thickness: 0.3-3mm; Width: 4-8m size in accordance to person requirements.

Features:

Geomembrane is a water-resistant barrier cloth based totally on excessive molecular polymer.

Main Product: High Density Polyethylene (HDPE) Geomembrane

1. Complete width and thickness specifications.

2. It has high-quality environmental stress cracking resistance and extraordinarily accurate chemical corrosion resistance.

3. Excellent chemical corrosion resistance.

4. It has a massive running temperature vary and a lengthy carrier life.

5. It is frequently used in anti-seepage and sealing duties such as aquaculture, sewage treatment tanks and landfills.

Application:

As a mature anti-seepage technology, polyethylene geomembrane has been greatly used in pretty a range bolstered anti-seepage duties such as tunnels, airports, metallurgical water conservancy, transportation, mine tailings, garbage disposal sites, and roof anti-seepage, basically in water conservancy projects. play an crucial feature in the mainstay

Product Implementation Standards: America GRI GM-13 Standard

HDPE Geomembrane Technical Parameter (GRI GM13 ASTM Standard) | ||||||||

Spec Properties | Test | GMS0.5 | GMS0.75 | GMS1.0 | GMS1.25 | GMS1.5 | GMS2.0 | GMS2.5 |

Thickness | D5199 | 0.5mm | 0.75mm | 1.00mm | 1 .25mm | 1.50mm | 2.00mm | 2.50mm |

Density (≥ g/cc) | D1505 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 |

Tensile Properties | D6693 Type IV | 8 kN/m 14 kN/m 12% 700% | 11 kN/m | 15 kN/m | 18 kN/m | 22 kN/m 40 kN/m 12% 700% | 29kN/m 53 KN/m 12% 700% | 37kN/m 67kN/m 12% 700% |

Tear Resistance (≥) | D 1004 | 64N | 93N | 125 N | 156N | 187N | 249 N | 311 N |

Puncture Resistance(≥) | D 4833 | 160N | 240N | 320 N | 400 N | 480N | 640 N | 800 N |

Stress Crack Resistance (≥) | D 5397 | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr |

Carbon Black Content | D 1603 | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% |

Carbon Black Dispersion | D 5596 | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) |

Oxidative Induction Time(OIT)(≥) (a)Standard OIT ——or—— | D 3895 D 5885 | 100 min | 100 min | 100 min | 100 min | 100 min | 100 min | 100 min |

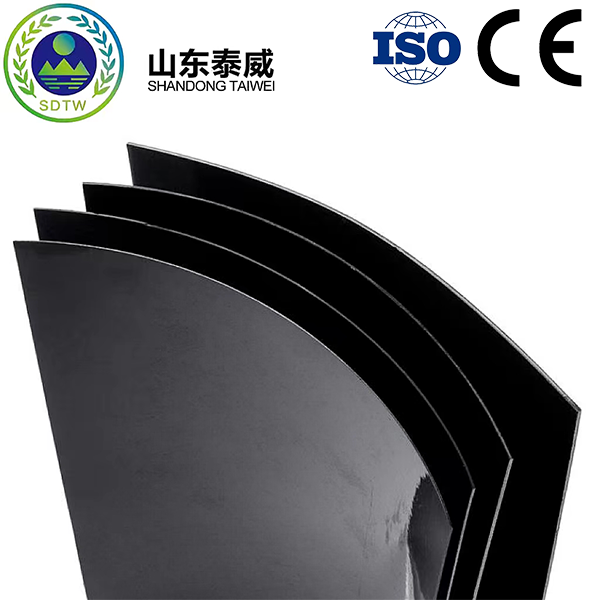

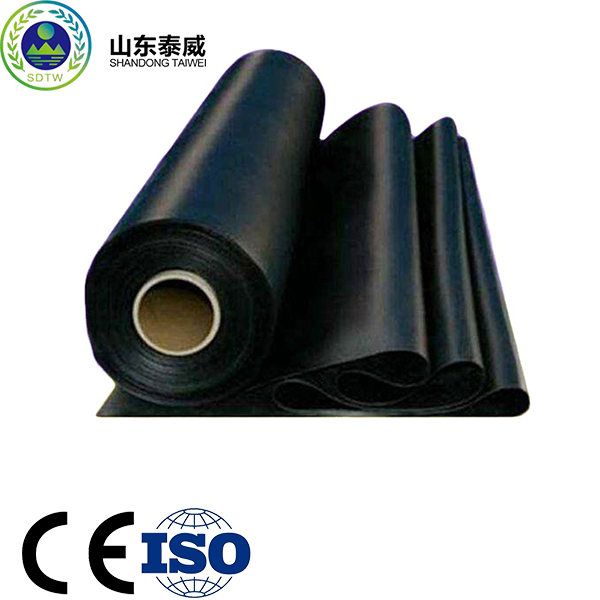

Packing of High Quality Good anti-seepage performance HDPE geomembrane

Equipment of High Quality Good anti-seepage performance HDPE geomembrane

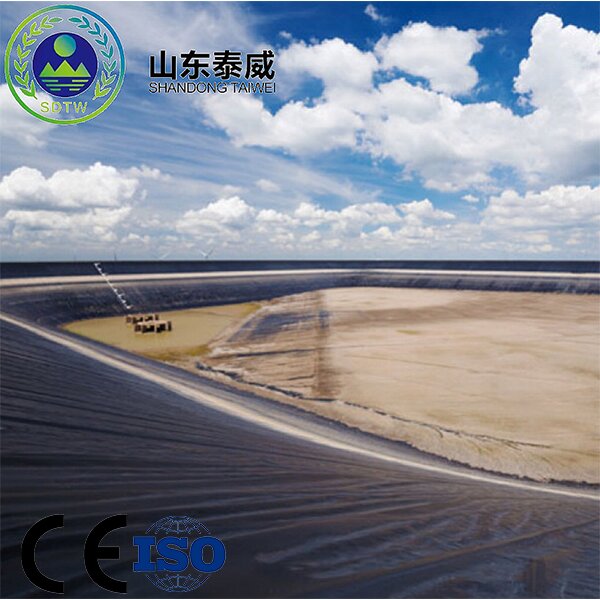

Usage Scenarios of High Quality Good anti-seepage performance HDPE geomembrane

Company Profile

The company's primary industries consist of geosynthetics, geotextiles and plastic products, and its merchandise have installed a true company picture in home and overseas markets. The agency has quality manufacturing equipment, and can furnish a number of geotechnical substances in accordance to person requirements, which are divided into various categories: geotextile, geomembrane, geogrid, drainage board, composite geomembrane, bentonite water-resistant blanket, geocell, geotechnical internet etc.

HDPE Geomembrane Technical Parameter (GRI GM13 ASTM Standard) | ||||||||

Spec Properties | Test | GMS0.5 | GMS0.75 | GMS1.0 | GMS1.25 | GMS1.5 | GMS2.0 | GMS2.5 |

Thickness | D5199 | 0.5mm | 0.75mm | 1.00mm | 1 .25mm | 1.50mm | 2.00mm | 2.50mm |

Density (≥ g/cc) | D1505 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 |

Tensile Properties | D6693 Type IV | 8 kN/m 14 kN/m 12% 700% | 11 kN/m | 15 kN/m | 18 kN/m | 22 kN/m 40 kN/m 12% 700% | 29kN/m 53 KN/m 12% 700% | 37kN/m 67kN/m 12% 700% |

Tear Resistance (≥) | D 1004 | 64N | 93N | 125 N | 156N | 187N | 249 N | 311 N |

Puncture Resistance(≥) | D 4833 | 160N | 240N | 320 N | 400 N | 480N | 640 N | 800 N |

Stress Crack Resistance (≥) | D 5397 | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr |

Carbon Black Content | D 1603 | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% |

Carbon Black Dispersion | D 5596 | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) |

Oxidative Induction Time(OIT)(≥) (a)Standard OIT ——or—— | D 3895 D 5885 | 100 min | 100 min | 100 min | 100 min | 100 min | 100 min | 100 min |

Related Products

Submitted successfully

We will contact you as soon as possible

Submitted successfully

We will contact you as soon as possible