Environmental Protection HDPE Geomembrane

Environmental Protection HDPE Geomembrane-use of polyethylene virgin resin, its necessary elements are 97.5% high-density polyethylene, about 2.5% carbon black, anti-aging agent, antioxidant, ultraviolet absorber, stabilizers, and exceptional auxiliary materials.

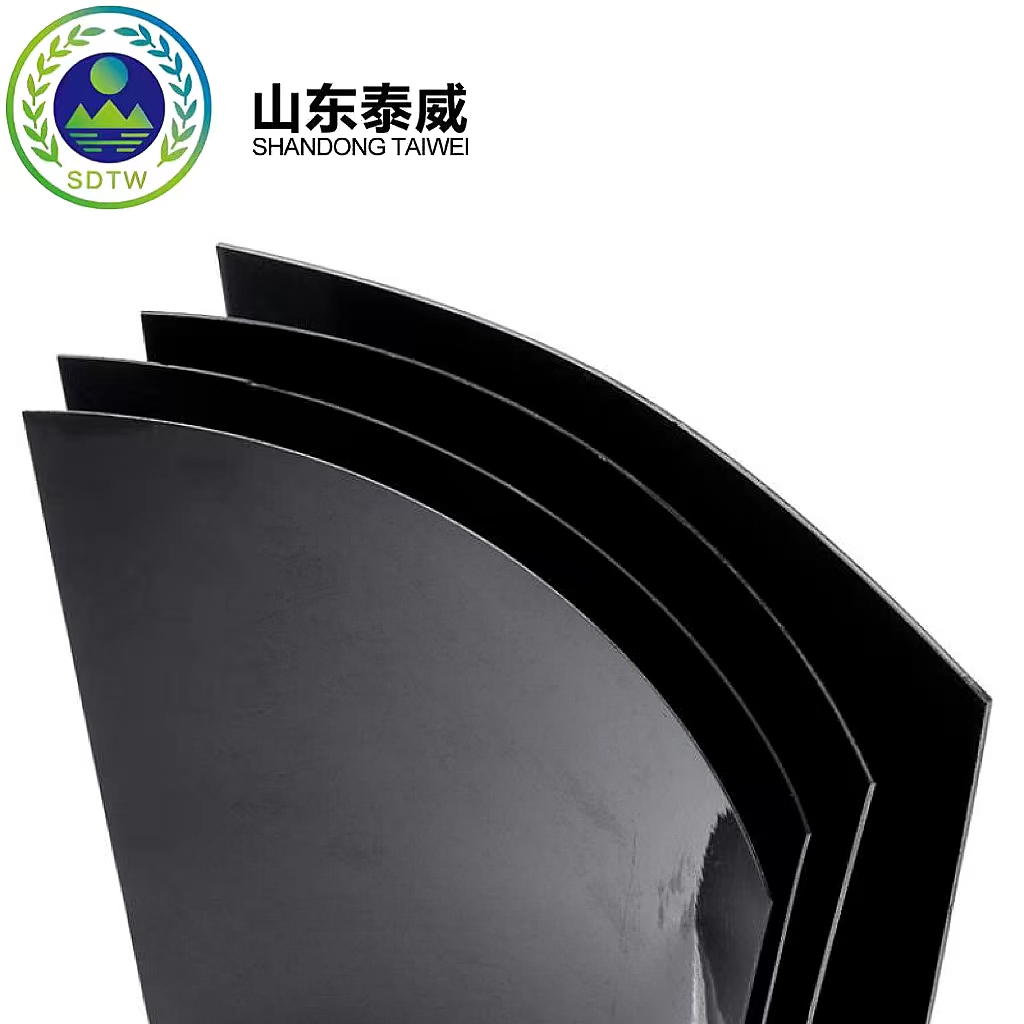

Product specification: Thickness: 0.3-3mm; Width: 4-8m size in accordance to person requirements.

Product Implementation Standards: America GRI GM-13 Standard

Environmental Protection HDPE Geomembrane

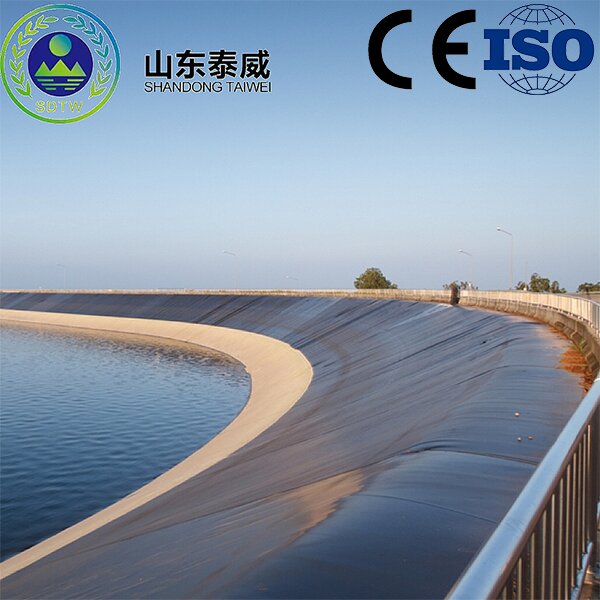

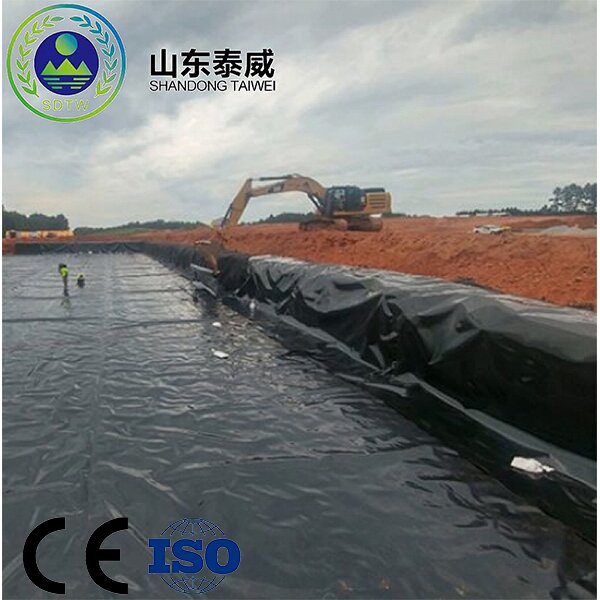

Environmental Protection HDPE Geomembrane is a new kind of material, HDPE geomembrane has first-rate anti-seepage, anti-corrosion performance, excellent chemical stability, and can be processed in accordance with authentic engineering needs. It has been extensively used in dikes, dams, and reservoirs of water conservancy projects. Anti-seepage, however additionally used as anti-seepage, anti-corrosion, leak-proof, and moisture-proof substances in channels, reservoirs, sewage pools, swimming pools, housing construction, underground buildings, rubbish dumps, and environmental engineering.

HDPE Geomembrane Technical Parameter (GRI GM13 ASTM Standard) | ||||||||

Spec Properties | Test | GMS0.5 | GMS0.75 | GMS1.0 | GMS1.25 | GMS1.5 | GMS2.0 | GMS2.5 |

Thickness | D5199 | 0.5mm | 0.75mm | 1.00mm | 1 .25mm | 1.50mm | 2.00mm | 2.50mm |

Density (≥ g/cc) | D1505 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 |

Tensile Properties | D6693 Type IV | 8 kN/m 14 kN/m 12% 700% | 11 kN/m | 15 kN/m | 18 kN/m | 22 kN/m 40 kN/m 12% 700% | 29kN/m 53 KN/m 12% 700% | 37kN/m 67kN/m 12% 700% |

Tear Resistance (≥) | D 1004 | 64N | 93N | 125 N | 156N | 187N | 249 N | 311 N |

Puncture Resistance(≥) | D 4833 | 160N | 240N | 320 N | 400 N | 480N | 640 N | 800 N |

Stress Crack Resistance (≥) | D 5397 | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr |

Carbon Black Content | D 1603 | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% |

Carbon Black Dispersion | D 5596 | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) |

Oxidative Induction Time(OIT)(≥) (a)Standard OIT ——or—— | D 3895 D 5885 | 100 min | 100 min | 100 min | 100 min | 100 min | 100 min | 100 min |

Application:

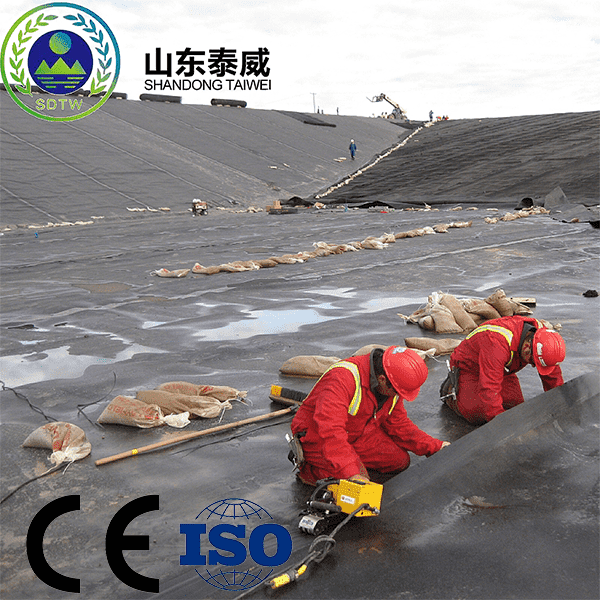

Made with the resource of three-layer co-extrusion technology. Meet the utility requirements of environmental sanitation, municipal engineering, sewage treatment, petrochemical industry, domestic waste landfill, artificial lake, water conservancy, construction, gardens, landscape, metallurgy, mining, salt industry, agriculture, aquaculture and distinct fields.

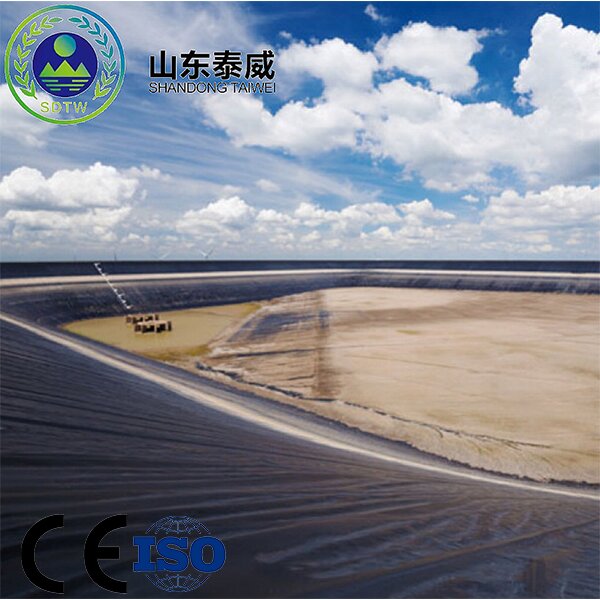

Usage Scenarios of Environmental Protection HDPE Geomembrane

Packing of Environmental Protection HDPE Geomembrane

Equipment of Environmental Protection HDPE Geomembrane

Features:

1. Environmental Protection HDPE geomembrane is a bendy water-resistant fabric with an excessive anti-seepage coefficient (1×10-17 cm/s);

2. Environmental Protection HDPE geomembrane has proper warmth resistance and bloodless resistance, and its working surroundings temperature is the excessive temperature of a hundred and ten ℃, low temperature -70 ℃;

3. Environmental Protection HDPE geomembrane has proper chemical stability, can face up to the corrosion of sturdy acid, alkali, and oil, and is a properly anti-corrosion material;

4. Environmental Protection HDPE geomembrane has excessive tensile strength so that it has excessive tensile electricity and can meet the wants of high-standard engineering projects;

5. Environmental Protection HDPE geomembrane has sturdy climate resistance, robust anti-aging performance, and can be used uncovered for a lengthy time whilst retaining the unique performance;

6. The normal overall performance of Environmental Protection HDPE geomembrane, HDPE geomembrane has sturdy tensile power and elongation at break, so HDPE geomembrane can be used in a variety of harsh geological and climatic conditions. Adapt to an uneven geological agreement and robust strain!

7. Environmental Protection HDPE geomembrane makes use of top-notch uncooked plastic and carbon black particles except any preservatives. HDPE has been used in the united states of America to exchange PVC as uncooked cloth for meals packaging baggage and fresh-keeping films.

Company Profile

Our employer has mechanical equipment, technical personnel, and a massive manufacturing team. The annual manufacturing of geotextiles is greater than 30 million rectangular meters, and the composite geomembrane is extra than 10 million rectangular meters. The employer will adhere to the working precept of "integrity-based, gratitude first", make pals from all over the world, cooperate and win-win, and are seeking frequent development.

HDPE Geomembrane Technical Parameter (GRI GM13 ASTM Standard) | ||||||||

Spec Properties | Test | GMS0.5 | GMS0.75 | GMS1.0 | GMS1.25 | GMS1.5 | GMS2.0 | GMS2.5 |

Thickness | D5199 | 0.5mm | 0.75mm | 1.00mm | 1 .25mm | 1.50mm | 2.00mm | 2.50mm |

Density (≥ g/cc) | D1505 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 |

Tensile Properties | D6693 Type IV | 8 kN/m 14 kN/m 12% 700% | 11 kN/m | 15 kN/m | 18 kN/m | 22 kN/m 40 kN/m 12% 700% | 29kN/m 53 KN/m 12% 700% | 37kN/m 67kN/m 12% 700% |

Tear Resistance (≥) | D 1004 | 64N | 93N | 125 N | 156N | 187N | 249 N | 311 N |

Puncture Resistance(≥) | D 4833 | 160N | 240N | 320 N | 400 N | 480N | 640 N | 800 N |

Stress Crack Resistance (≥) | D 5397 | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr |

Carbon Black Content | D 1603 | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% |

Carbon Black Dispersion | D 5596 | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) |

Oxidative Induction Time(OIT)(≥) (a)Standard OIT ——or—— | D 3895 D 5885 | 100 min | 100 min | 100 min | 100 min | 100 min | 100 min | 100 min |