High Performance HDPE Rough Geomembrane

High Performance HDPE Rough Geomembrane-The tough ground geomembrane is particularly based totally on the normal manufacturing device of the anti-seepage membrane, and the manufacturing equipment is technologically transformed. The anti-seepage influence is good, and the permeability coefficient is a whole lot much less than 10~17cm/s.

At the equal time, in distinction with the smooth anti-seepage membrane of the equal specification, in initiatives the area the ground of the slope membrane physique needs to be blanketed with soil and requires a massive amazing coefficient of friction, the tensile electrical energy is stronger. High, no longer handy to leak.

In the process, if there is a pipeline that needs to miss through the membrane, the difficult flooring geomembrane want to be welded, and the unique method of "pipe-through-membrane" ought to be used to elevate out constructing with greater adsorption or degradation performance, and do away with suspended or dissolved air air pollution components.

High Performance HDPE Rough Geomembrane

The tough flooring geomembrane is used as the anti-seepage base material. It is a geotechnical anti-seepage material processed through ability of a extraordinary manner aspects by means of the resin raw material with the aid of roller extrusion or blown film roughening. The basic overall performance of the new fabric geomembrane is frequently isolation and anti-seepage performance. . They are a kind of polymer chemical flexible cloth with small specific gravity, sturdy extensibility, immoderate adaptability to deformation, corrosion resistance, low temperature resistance and exact frost resistance. The single hard ground and double hard flooring geomembrane can enlarge the friction coefficient with the contact ground and enhance the anti-slip attribute of the geomembrane. It is broadly speaking suitable for slopes, steep slopes and vertical anti-seepage to beautify mission stability.

Product specification:

Thickness: 0.3-3mm; Width: 4-8m size in accordance to consumer requirements.

Double anti-oxidation: anti-ultraviolet, anti-oxidation can be personalized.

Features:

Geomembrane is a water-resistant barrier cloth primarily based on excessive molecular polymer.

Main Product: High Density Polyethylene (HDPE) Geomembrane

1. Complete width and thickness specifications.

2. It has outstanding environmental stress cracking resistance and tremendous chemical corrosion resistance.

3. Excellent chemical corrosion resistance.

4. It has a giant working temperature vary and a lengthy carrier life.

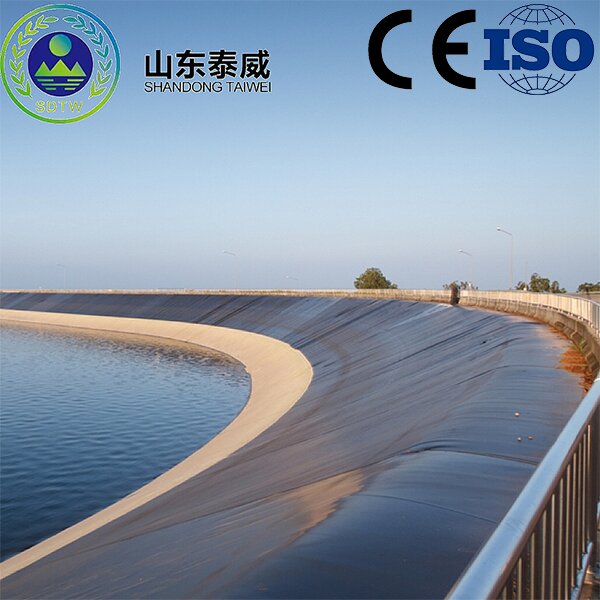

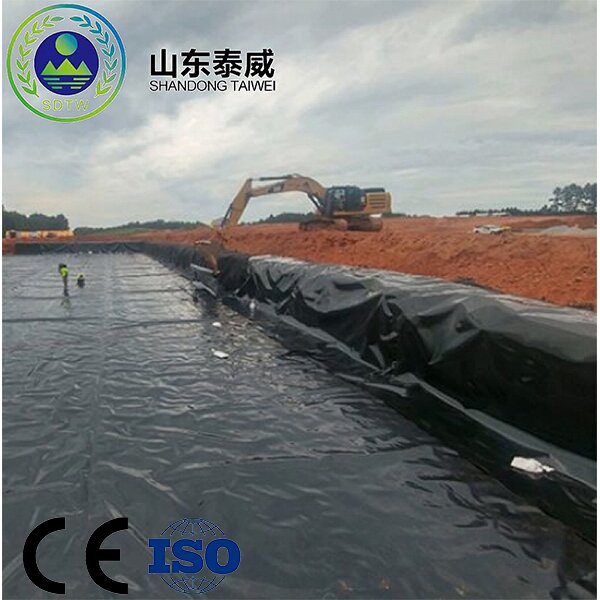

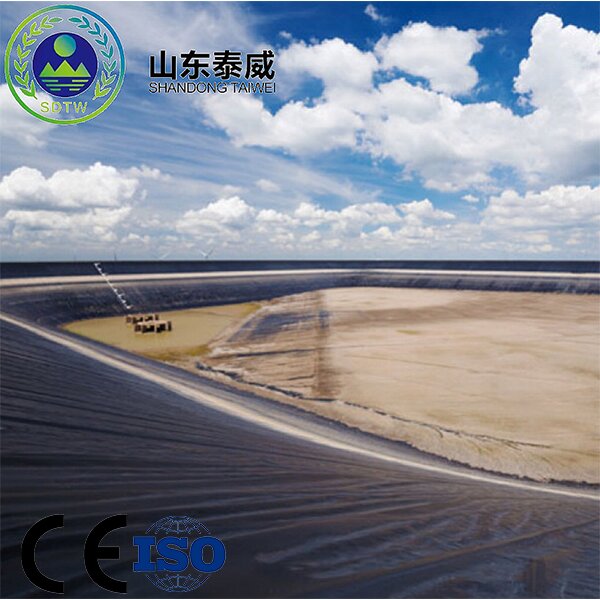

5. It is frequently used in anti-seepage and sealing duties such as aquaculture, sewage treatment tanks and landfills.

Application:

As a mature anti-seepage technology, polyethylene geomembrane has been broadly used in a range of strengthened anti-seepage initiatives such as tunnels, airports, metallurgical water conservancy, transportation, mine tailings, rubbish disposal sites, and roof anti-seepage, in particular in water conservancy projects. play an vital position in the mainstay.

Product Implementation Standards: America GRI GM-13 Standard

HDPE Geomembrane Technical Parameter (GRI GM13 ASTM Standard) | ||||||||

Spec Properties | Test | GMS0.5 | GMS0.75 | GMS1.0 | GMS1.25 | GMS1.5 | GMS2.0 | GMS2.5 |

Thickness | D5199 | 0.5mm | 0.75mm | 1.00mm | 1 .25mm | 1.50mm | 2.00mm | 2.50mm |

Density (≥ g/cc) | D1505 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 |

Tensile Properties | D6693 Type IV | 8 kN/m 14 kN/m 12% 700% | 11 kN/m | 15 kN/m | 18 kN/m | 22 kN/m 40 kN/m 12% 700% | 29kN/m 53 KN/m 12% 700% | 37kN/m 67kN/m 12% 700% |

Tear Resistance (≥) | D 1004 | 64N | 93N | 125 N | 156N | 187N | 249 N | 311 N |

Puncture Resistance(≥) | D 4833 | 160N | 240N | 320 N | 400 N | 480N | 640 N | 800 N |

Stress Crack Resistance (≥) | D 5397 | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr |

Carbon Black Content | D 1603 | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% |

Carbon Black Dispersion | D 5596 | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) |

Oxidative Induction Time(OIT)(≥) (a)Standard OIT ——or—— | D 3895 D 5885 | 100 min | 100 min | 100 min | 100 min | 100 min | 100 min | 100 min |

Packing of High Performance HDPE Rough Geomembrane

Equipment of High Performance HDPE Rough Geomembrane

Usage Scenarios of High Performance HDPE Rough Geomembrane

Company Profile

The enterprise has swiftly developed into a high-tech non-public organisation specializing in the manufacturing and lookup of geosynthetics and new composite materials, and has effectively handed the three main machine certifications and product security CE certification. The geotechnical substances produced via the business enterprise have been amongst the satisfactory in the identical enterprise in the us of a for many years. Its merchandise are extensively used in the fields of road, railway, machinery, water conservancy, electric powered power, soil and water conservation, environmental greening and infrastructure construction. The merchandise are notably praised via home and overseas specialists in the engineering subject and users.

HDPE Geomembrane Technical Parameter (GRI GM13 ASTM Standard) | ||||||||

Spec Properties | Test | GMS0.5 | GMS0.75 | GMS1.0 | GMS1.25 | GMS1.5 | GMS2.0 | GMS2.5 |

Thickness | D5199 | 0.5mm | 0.75mm | 1.00mm | 1 .25mm | 1.50mm | 2.00mm | 2.50mm |

Density (≥ g/cc) | D1505 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 |

Tensile Properties | D6693 Type IV | 8 kN/m 14 kN/m 12% 700% | 11 kN/m | 15 kN/m | 18 kN/m | 22 kN/m 40 kN/m 12% 700% | 29kN/m 53 KN/m 12% 700% | 37kN/m 67kN/m 12% 700% |

Tear Resistance (≥) | D 1004 | 64N | 93N | 125 N | 156N | 187N | 249 N | 311 N |

Puncture Resistance(≥) | D 4833 | 160N | 240N | 320 N | 400 N | 480N | 640 N | 800 N |

Stress Crack Resistance (≥) | D 5397 | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr |

Carbon Black Content | D 1603 | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% |

Carbon Black Dispersion | D 5596 | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) |

Oxidative Induction Time(OIT)(≥) (a)Standard OIT ——or—— | D 3895 D 5885 | 100 min | 100 min | 100 min | 100 min | 100 min | 100 min | 100 min |