High Quality HDPE Geomembrane Pond Liner

HDPE geomembrane ;

Product specifications; Thickness; 0.3-3.0mm, width 1-8 meters, helps customization

Product characteristics; HDPE geomembrane has proper resistance to environmental stress cracking, big company temperature (-60-+60), and prolonged service existence (≥50 years)

Application scope; Merit in water conservancy, aquaculture, fish ponds, and so forth

High density anti-seepage and corrosion-resistant hdpe geomembrane

Product Introduction:

HDPE geomembrane, additionally recognised as (anti-seepage liner), is a movie made of high-density polyethylene material. It has steady chemical properties, many special product traits and a huge vary of applications.

Features:

1. Strong durability: HDPE geomembrane has genuine sturdiness and anti-aging properties, and can keep tightly closed bodily homes for a prolonged time.

2. Chemical corrosion resistance: HDPE geomembrane has immoderate corrosion resistance to most chemical compounds and can successfully shield soil and water sources from pollution.

3. High tensile strength: HDPE geomembrane has awesome tensile strength, can stand up to positive exterior forces and pressures, and has awesome tensile properties.

4. Anti-permeability: HDPE geomembrane has immoderate permeability barrier ability, which can efficiently prevent the penetration of water, gas and chemical substances, and play the feature of anti-penetration and isolation.

5. Good flexibility: HDPE geomembrane has right flexibility and bending performance, and is excellent for a wide variety of terrains and environmental conditions.

Application:

1. Anti-penetration projects: HDPE geomembrane is substantially used in anti-penetration projects, such as anti-penetration layers in landfills, wastewater remedy plants, chemical plants, electrical energy plants, etc.

2. Agricultural engineering: HDPE geomembrane can be used as the anti-penetration layer of reservoirs, channels, ponds, etc. in agricultural water conservancy initiatives to maintain away from the waste of water resources.

3. Road and railway projects: HDPE geomembrane can be used as a water resistant layer for avenue and railway projects, successfully maintaining aside the ground from the underlying soil and stopping moisture from penetrating and inflicting harm to the road surface.

4. Underground water transmission project: HDPE geomembrane can be used as the anti-penetration layer of underground water pipelines to make positive the purity of water sources and the reliability of supply.

5. Construction projects: HDPE geomembrane can be used as a water resistant layer in constructing projects, such as roof waterproofing, basement waterproofing, etc.

Product Implementation Standards: ASTM Standard

HDPE Geomembrane Technical Parameter (GRI GM13 ASTM Standard) | ||||||||

Spec Properties | Test | GMS0.5 | GMS0.75 | GMS1.0 | GMS1.25 | GMS1.5 | GMS2.0 | GMS2.5 |

Thickness | D5199 | 0.5mm | 0.75mm | 1.00mm | 1 .25mm | 1.50mm | 2.00mm | 2.50mm |

Density (≥ g/cc) | D1505 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 |

Tensile Properties | D6693 Type IV | 8 kN/m 14 kN/m 12% 700% | 11 kN/m | 15 kN/m | 18 kN/m | 22 kN/m 40 kN/m 12% 700% | 29kN/m 53 KN/m 12% 700% | 37kN/m 67kN/m 12% 700% |

Tear Resistance (≥) | D 1004 | 64N | 93N | 125 N | 156N | 187N | 249 N | 311 N |

Puncture Resistance(≥) | D 4833 | 160N | 240N | 320 N | 400 N | 480N | 640 N | 800 N |

Stress Crack Resistance (≥) | D 5397 | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr |

Carbon Black Content | D 1603 | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% |

Carbon Black Dispersion | D 5596 | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) |

Oxidative Induction Time(OIT)(≥) (a)Standard OIT ——or—— | D 3895 D 5885 | 100 min | 100 min | 100 min | 100 min | 100 min | 100 min | 100 min |

HDPE geomembrane plastic packaging

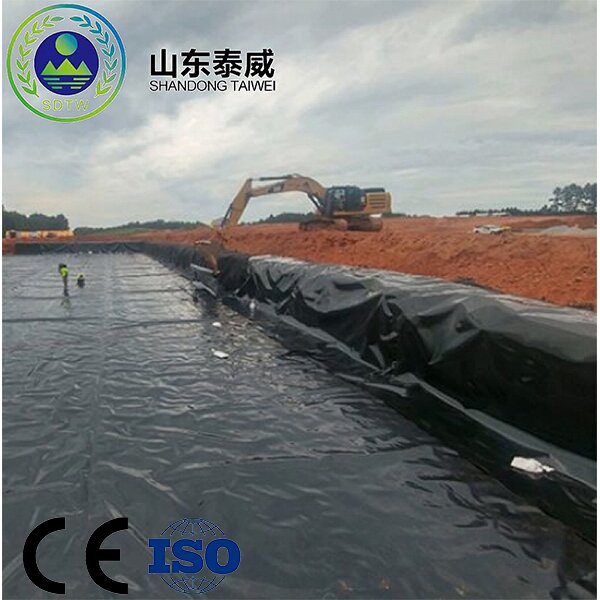

Equipment of High Quality Good anti-seepage performance HDPE geomembrane

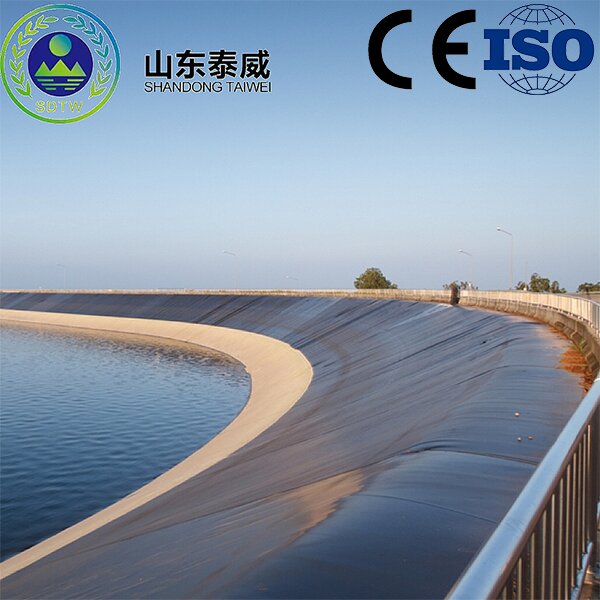

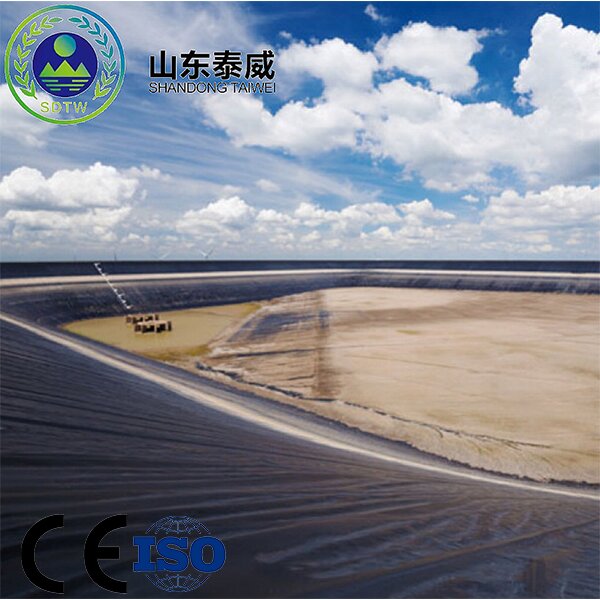

Usage Scenarios of High Quality Good anti-seepage performance HDPE geomembrane

HDPE Geomembrane Technical Parameter (GRI GM13 ASTM Standard) | ||||||||

Spec Properties | Test | GMS0.5 | GMS0.75 | GMS1.0 | GMS1.25 | GMS1.5 | GMS2.0 | GMS2.5 |

Thickness | D5199 | 0.5mm | 0.75mm | 1.00mm | 1 .25mm | 1.50mm | 2.00mm | 2.50mm |

Density (≥ g/cc) | D1505 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 |

Tensile Properties | D6693 Type IV | 8 kN/m 14 kN/m 12% 700% | 11 kN/m | 15 kN/m | 18 kN/m | 22 kN/m 40 kN/m 12% 700% | 29kN/m 53 KN/m 12% 700% | 37kN/m 67kN/m 12% 700% |

Tear Resistance (≥) | D 1004 | 64N | 93N | 125 N | 156N | 187N | 249 N | 311 N |

Puncture Resistance(≥) | D 4833 | 160N | 240N | 320 N | 400 N | 480N | 640 N | 800 N |

Stress Crack Resistance (≥) | D 5397 | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr |

Carbon Black Content | D 1603 | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% |

Carbon Black Dispersion | D 5596 | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) |

Oxidative Induction Time(OIT)(≥) (a)Standard OIT ——or—— | D 3895 D 5885 | 100 min | 100 min | 100 min | 100 min | 100 min | 100 min | 100 min |