High Quality HDPE Pond Liner for Aquaculture Engineering

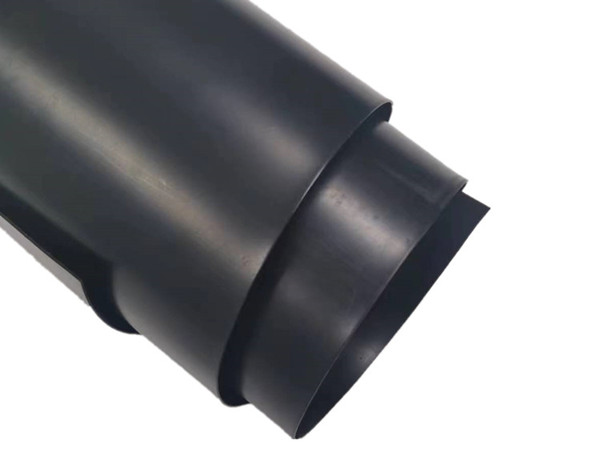

HDPE geomembrane ;

Product specifications; Thickness; 0.3-3.0mm, width 1-8 meters, helps customization

Product characteristics; HDPE geomembrane has proper resistance to environmental stress cracking, big company temperature (-60-+60), and prolonged service existence (≥50 years)

Application scope; Merit in water conservancy, aquaculture, fish ponds, and so forth

High Quality HDPE Pond Liner for Aquaculture Engineering

Product Introduction:

HDPE geomembrane is widely used in various engineering fields. It is mainly used for anti-seepage, anti-corrosion, waterproofing, etc. It can effectively protect engineering structures, extend service life and reduce maintenance costs.

Features:

1. HDPE geomembrane has good chemical stability and can resist the corrosion of strong acids, alkali and oil, and is a good anti-corrosion material;

2. HDPE geomembrane has high tensile strength, which enables it to meet the needs of high-standard engineering projects;

3. HDPE geomembrane has strong weather resistance and anti-aging performance, and can be used exposed for a long time while maintaining its original performance;

4. The overall performance of HDPE geomembrane. HDPE geomembrane has strong tensile strength and elongation at break, which enables HDPE geomembrane to be used in various harsh geological and climatic conditions. Adaptable to uneven geological settlement and strong strain resistance!

Application:

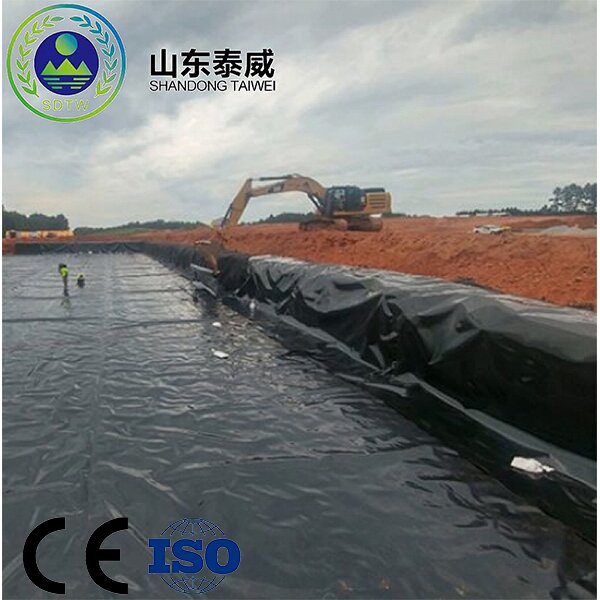

1. HDPE geomembrane is suitable for environmental protection and sanitation: such as landfills, sewage treatment plants, power plant regulating pools, industrial and hospital solid wastes, etc.;

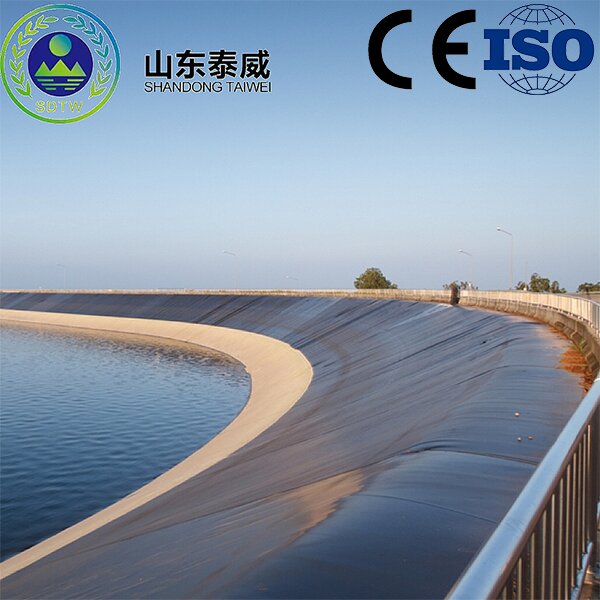

2. HDPE geomembrane is suitable for water conservancy projects: such as anti-seepage, plugging, and reinforcement of rivers, lakes, reservoirs, and dams, anti-seepage of water channels, vertical core walls, slope protection, etc.;

3. HDPE geomembrane is used in municipal projects: subways, underground engineering projects of buildings, planting roofs, roof gardens, and sewage pipe anti-seepage;

4. HDPE geomembrane is suitable for aquaculture industry: intensive and factory farming ponds, fish ponds, lining of shrimp ponds, sea cucumber circle slope protection, etc.;

5. Polyethylene anti-seepage membrane is suitable for gardens: artificial lakes, rivers, reservoirs, pond bottoms of golf courses, slope protection, green lawns, etc.;

Product Implementation Standards: ASTM Standard

HDPE Geomembrane Technical Parameter (GRI GM13 ASTM Standard) | ||||||||

Spec Properties | Test | GMS0.5 | GMS0.75 | GMS1.0 | GMS1.25 | GMS1.5 | GMS2.0 | GMS2.5 |

Thickness | D5199 | 0.5mm | 0.75mm | 1.00mm | 1 .25mm | 1.50mm | 2.00mm | 2.50mm |

Density (≥ g/cc) | D1505 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 |

Tensile Properties | D6693 Type IV | 8 kN/m 14 kN/m 12% 700% | 11 kN/m | 15 kN/m | 18 kN/m | 22 kN/m 40 kN/m 12% 700% | 29kN/m 53 KN/m 12% 700% | 37kN/m 67kN/m 12% 700% |

Tear Resistance (≥) | D 1004 | 64N | 93N | 125 N | 156N | 187N | 249 N | 311 N |

Puncture Resistance(≥) | D 4833 | 160N | 240N | 320 N | 400 N | 480N | 640 N | 800 N |

Stress Crack Resistance (≥) | D 5397 | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr |

Carbon Black Content | D 1603 | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% |

Carbon Black Dispersion | D 5596 | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) |

Oxidative Induction Time(OIT)(≥) (a)Standard OIT ——or—— | D 3895 D 5885 | 100 min | 100 min | 100 min | 100 min | 100 min | 100 min | 100 min |

HDPE geomembrane plastic packaging

Equipment of High Quality Good anti-seepage performance HDPE geomembrane

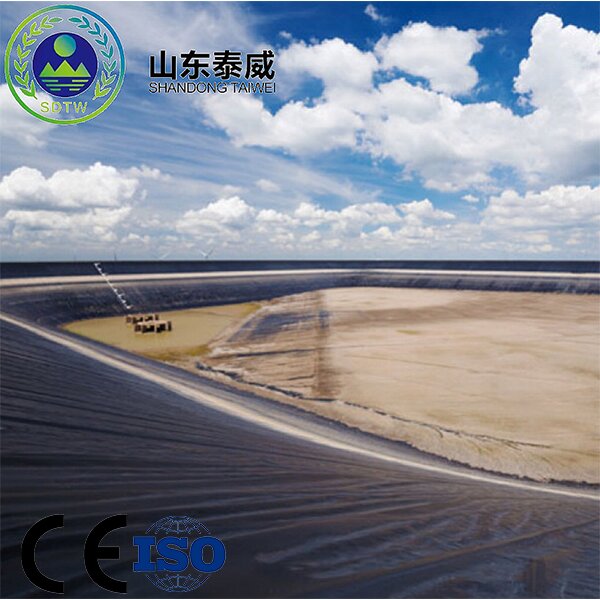

Usage Scenarios of High Quality Good anti-seepage performance HDPE geomembrane

HDPE Geomembrane Technical Parameter (GRI GM13 ASTM Standard) | ||||||||

Spec Properties | Test | GMS0.5 | GMS0.75 | GMS1.0 | GMS1.25 | GMS1.5 | GMS2.0 | GMS2.5 |

Thickness | D5199 | 0.5mm | 0.75mm | 1.00mm | 1 .25mm | 1.50mm | 2.00mm | 2.50mm |

Density (≥ g/cc) | D1505 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 |

Tensile Properties | D6693 Type IV | 8 kN/m 14 kN/m 12% 700% | 11 kN/m | 15 kN/m | 18 kN/m | 22 kN/m 40 kN/m 12% 700% | 29kN/m 53 KN/m 12% 700% | 37kN/m 67kN/m 12% 700% |

Tear Resistance (≥) | D 1004 | 64N | 93N | 125 N | 156N | 187N | 249 N | 311 N |

Puncture Resistance(≥) | D 4833 | 160N | 240N | 320 N | 400 N | 480N | 640 N | 800 N |

Stress Crack Resistance (≥) | D 5397 | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr |

Carbon Black Content | D 1603 | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% |

Carbon Black Dispersion | D 5596 | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) |

Oxidative Induction Time(OIT)(≥) (a)Standard OIT ——or—— | D 3895 D 5885 | 100 min | 100 min | 100 min | 100 min | 100 min | 100 min | 100 min |