High Tensile Strength LDPE Geomembrane

High Tensile Strength LDPE Geomembrane-It is specifically primarily based on plastic film. Compared with HDPE geomembrane, it has greater tensile electrical energy and flexibility. It is a extra moderen science of geotechnical anti-seepage material. LDPE geomembrane is in most cases composed of polyethylene, ethylene, ethylene polymer and exceptional materials.

On the basis of absorbing the flexibility of previous geomembranes, it has increased its specific extensibility and adaptability to deformation, extensively developing its Its water resistant and anti-seepage ability.

High Tensile Strength LDPE Geomembrane

High Tensile Strength LDPE Geomembrane is a non-toxic, tasteless and odorless white particle of immoderate molecular weight polymer, with a melting issue of about 110°C-130°C and a relative density of 0.918-0.965; it has pinnacle warmness resistance and cold resistance. Good chemical stability, immoderate anxiety and toughness, authentic mechanical strength, pinnacle resistance to environmental stress cracking and tear resistance, as the density increases, the mechanical homes and barrier residences will make larger accordingly, heat resistance, and tensile strength The electrical energy is moreover higher; it is resistant to corrosion such as acids, alkalis, and herbal solvents.

Product specification:

Thickness: 0.3-3mm; Width: 4-8m size in accordance to person requirements.

Features:

Strength - underneath the identical weight specification, the tensile power in all instructions is greater than different needle-punched non-woven fabrics.

Anti-ultraviolet mild - has extraordinarily excessive anti-ultraviolet ability.

Extremely excessive temperature resistance overall performance - excessive temperature resistance up to 230 ℃, and it nonetheless keeps structural integrity and unique bodily residences below excessive temperature.

Permeability and airplane drainage - the water resistant board is thick and needle-punched, with excellent airplane drainage and vertical water permeability, which can nonetheless hold this overall performance after many years.

Creep resistance - the creep resistance of the water-resistant board is higher than different geotextiles, so it has appropriate long-term performance. It is resistant to the erosion of frequent chemical compounds in the soil and the corrosion of gasoline, diesel, etc.

Extensibility - the water-proof board has a precise elongation charge below a sure stress, so that it can adapt to uneven and irregular base surfaces.

Application:

Uses: anti-seepage, isolation

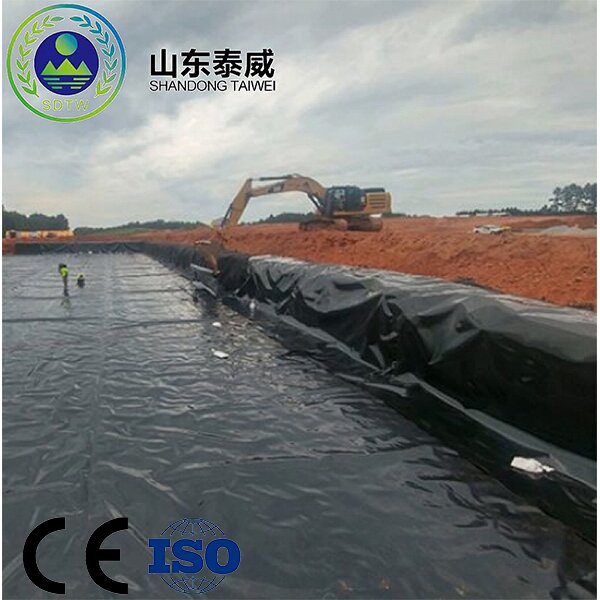

● Seepage prevention in landfills, sewage or waste disposal sites.

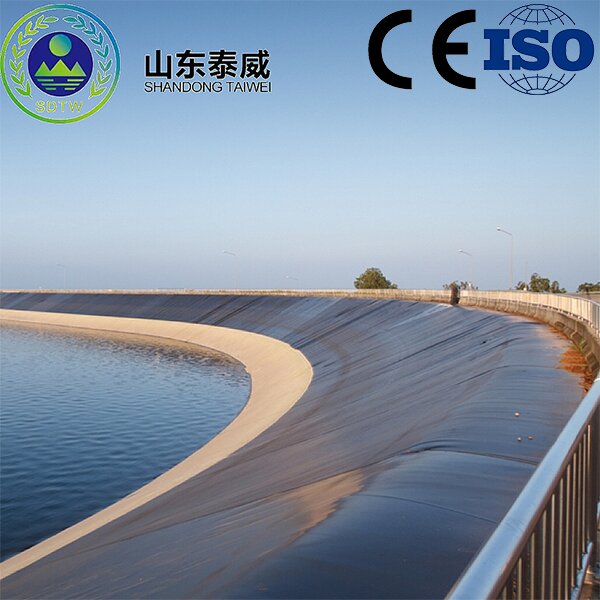

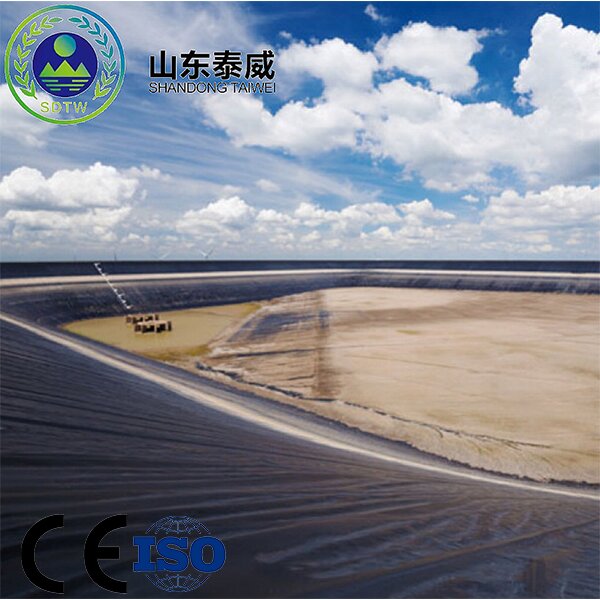

●River dikes, lake dams, tailings dams, sewage dams and reservoir areas, channels, reservoirs (pit, mine).

●Metro, basement and tunnel, anti-seepage lining of tunnel.

●Saline anti-seepage of roadbed and different foundations.

●Horizontal anti-seepage bedding in the front of dikes and dams, vertical anti-seepage layers for foundations, building cofferdams, and waste yards.

●Seawater and freshwater farms.

●Foundation of roads, highways and railways; water resistant layer of expansive soil and collapsible loess.

● Roof seepage prevention.

Product Implementation Standards:

Item | Project | Index |

1 | Thinkness mm | 0.2~3 |

2 | Width m | 2.5~9m |

3 | Tensile strength (vertical and horizontal) MPa | ≥14 |

4 | Elongation at break (vertical and horizontal) % | ≥400 |

5 | Right-angle tear strength N/mm | ≥50 |

6 | Water vapor permeability coefficient (g,cm/c㎡.s.pa) | <1.0×10-13 |

7 | Service temperature range | +70℃~-70℃ |

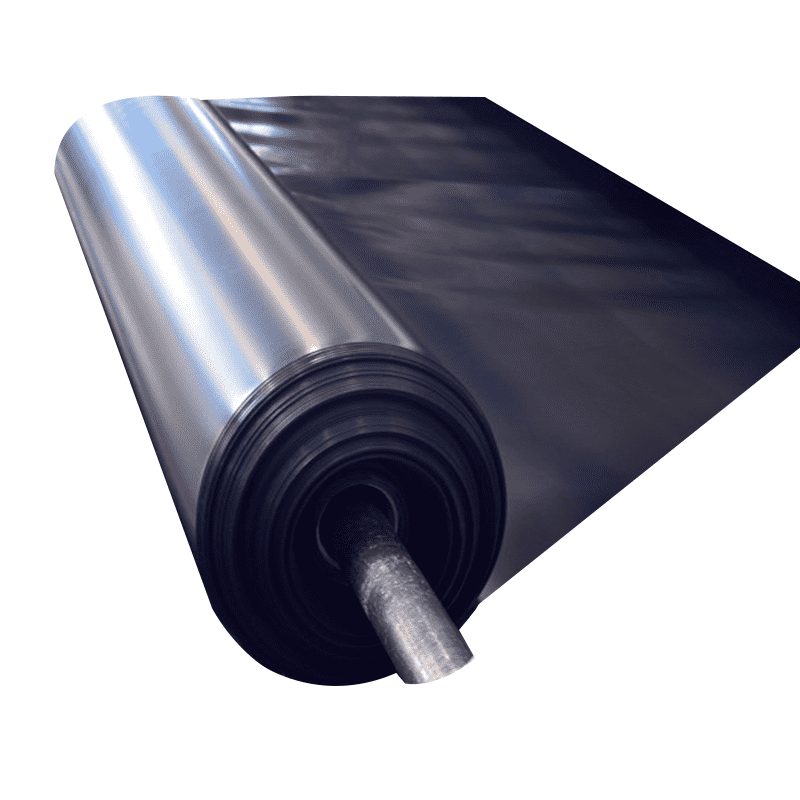

Packing of High Tensile Strength LDPE Geomembrane

Equipment of High Tensile Strength LDPE Geomembrane

Usage Scenarios of High Tensile Strength LDPE Geomembrane

Company Profile

Our organization has mechanical equipment, technical personnel and a massive manufacturing team. The annual manufacturing of geotextiles is extra than 30 million rectangular meters, and the composite geomembrane is greater than 10 million rectangular meters. The agency will adhere to the working precept of "integrity-based, gratitude first", make buddies from all over the world, cooperate and win-win, and are seeking frequent development.

HDPE Geomembrane Technical Parameter (GRI GM13 ASTM Standard) | ||||||||

Spec Properties | Test | GMS0.5 | GMS0.75 | GMS1.0 | GMS1.25 | GMS1.5 | GMS2.0 | GMS2.5 |

Thickness | D5199 | 0.5mm | 0.75mm | 1.00mm | 1 .25mm | 1.50mm | 2.00mm | 2.50mm |

Density (≥ g/cc) | D1505 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 |

Tensile Properties | D6693 Type IV | 8 kN/m 14 kN/m 12% 700% | 11 kN/m | 15 kN/m | 18 kN/m | 22 kN/m 40 kN/m 12% 700% | 29kN/m 53 KN/m 12% 700% | 37kN/m 67kN/m 12% 700% |

Tear Resistance (≥) | D 1004 | 64N | 93N | 125 N | 156N | 187N | 249 N | 311 N |

Puncture Resistance(≥) | D 4833 | 160N | 240N | 320 N | 400 N | 480N | 640 N | 800 N |

Stress Crack Resistance (≥) | D 5397 | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr |

Carbon Black Content | D 1603 | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% |

Carbon Black Dispersion | D 5596 | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) |

Oxidative Induction Time(OIT)(≥) (a)Standard OIT ——or—— | D 3895 D 5885 | 100 min | 100 min | 100 min | 100 min | 100 min | 100 min | 100 min |