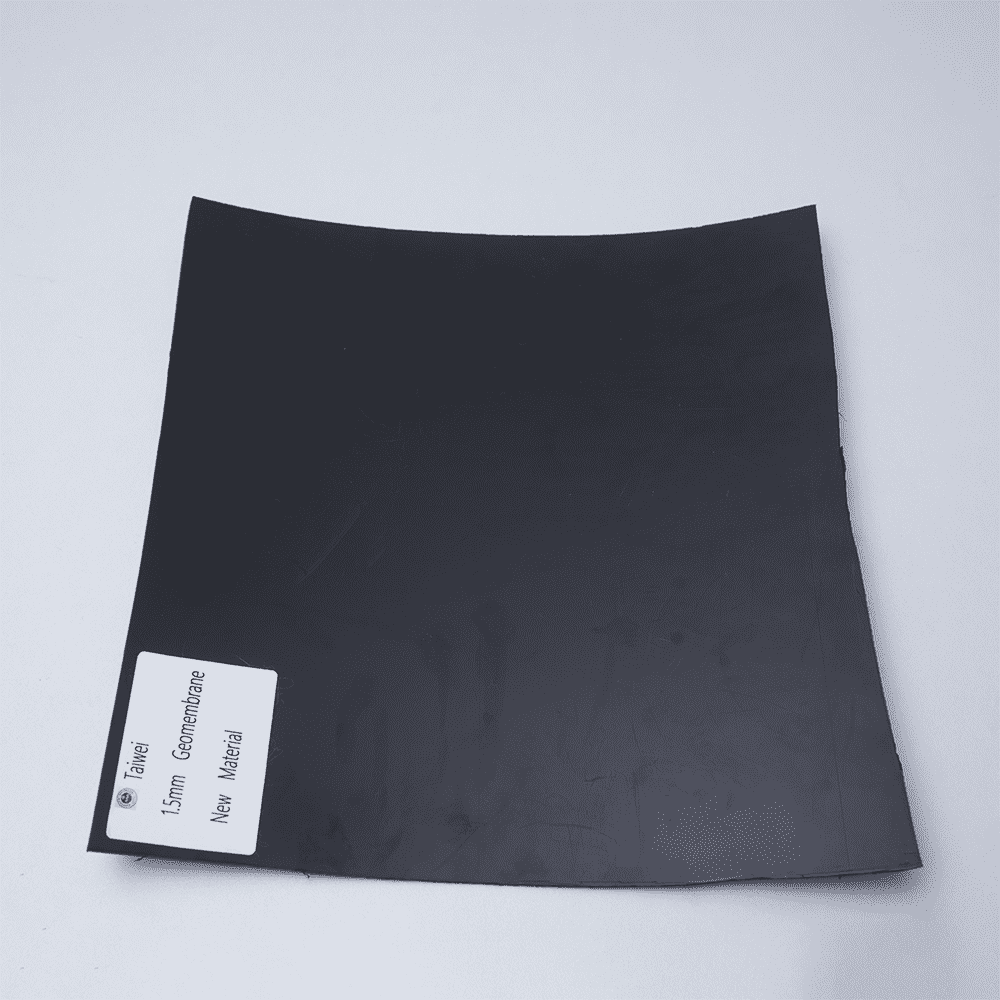

Pond Anti-seepage High Density Polyethylene Geomembrane

HDPE geomembrane ;

Product specifications; Thickness; 0.3-3.0mm, width 1-8 meters, helps customization

Product characteristics; HDPE geomembrane has proper resistance to environmental stress cracking, big company temperature (-60-+60), and prolonged service existence (≥50 years)

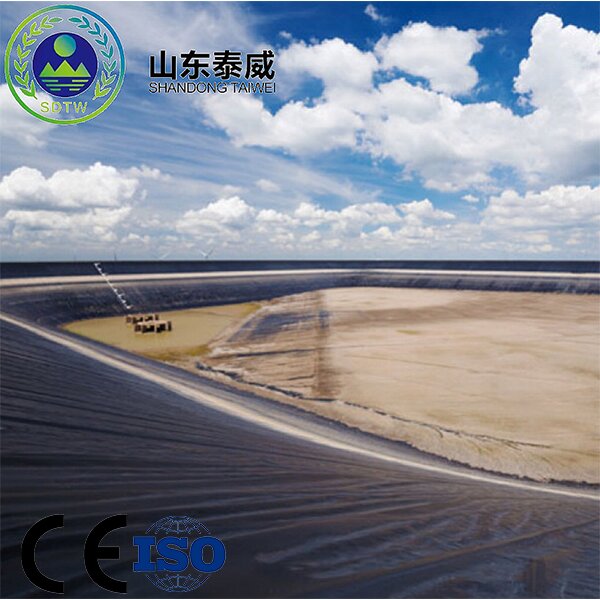

Application scope; Merit in water conservancy, aquaculture, fish ponds, and so forth

High density anti-seepage and corrosion-resistant hdpe geomembrane

Product Introduction:

HDPE geomembrane is widely used in various engineering fields. It is mainly used for anti-seepage, anti-corrosion, waterproofing, etc. It can effectively protect engineering structures, extend service life and reduce maintenance costs.

Features:

1. Good corrosion resistance: HDPE geomembrane can resist the erosion of chemicals such as acids and alkalis, and has excellent chemical resistance.

2. High strength and wear resistance: HDPE geomembrane has high strength and tensile resistance, is not easy to break, and can resist high mechanical wear.

3. Excellent anti-penetration performance: HDPE geomembrane has good waterproof performance and can effectively prevent water penetration in the soil.

Application:

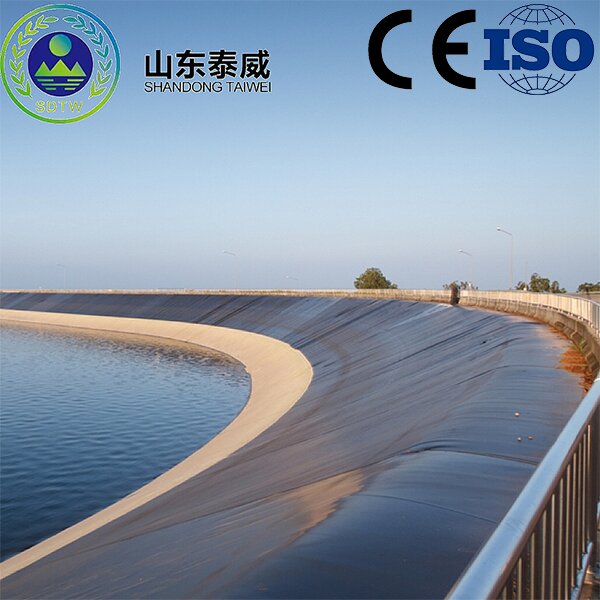

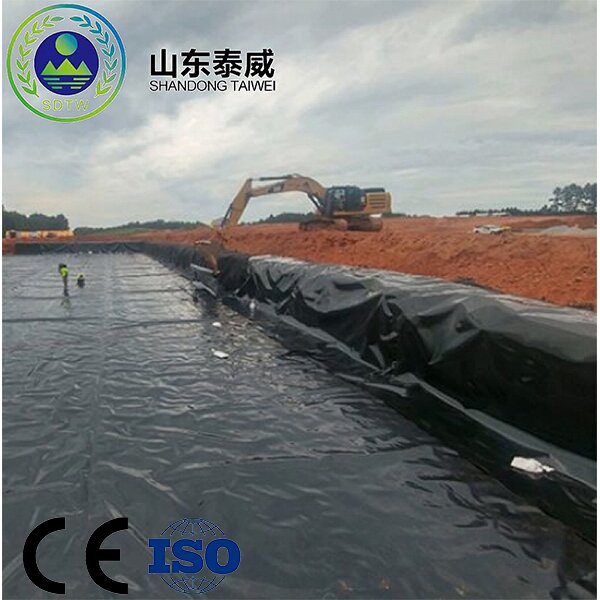

1. Anti-seepage materials in tunnels, underground projects and water conservancy projects

2. Anti-seepage layer in landfill

3. Anti-corrosion lining of sewage treatment plants and chemical plants

4. Anti-seepage layer of water conservancy projects such as reservoirs, dams, river embankments, etc.

5. Anti-seepage layer of agricultural channels and greenhouses

Product Implementation Standards: ASTM Standard

HDPE Geomembrane Technical Parameter (GRI GM13 ASTM Standard) | ||||||||

Spec Properties | Test | GMS0.5 | GMS0.75 | GMS1.0 | GMS1.25 | GMS1.5 | GMS2.0 | GMS2.5 |

Thickness | D5199 | 0.5mm | 0.75mm | 1.00mm | 1 .25mm | 1.50mm | 2.00mm | 2.50mm |

Density (≥ g/cc) | D1505 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 |

Tensile Properties | D6693 Type IV | 8 kN/m 14 kN/m 12% 700% | 11 kN/m | 15 kN/m | 18 kN/m | 22 kN/m 40 kN/m 12% 700% | 29kN/m 53 KN/m 12% 700% | 37kN/m 67kN/m 12% 700% |

Tear Resistance (≥) | D 1004 | 64N | 93N | 125 N | 156N | 187N | 249 N | 311 N |

Puncture Resistance(≥) | D 4833 | 160N | 240N | 320 N | 400 N | 480N | 640 N | 800 N |

Stress Crack Resistance (≥) | D 5397 | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr |

Carbon Black Content | D 1603 | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% |

Carbon Black Dispersion | D 5596 | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) |

Oxidative Induction Time(OIT)(≥) (a)Standard OIT ——or—— | D 3895 D 5885 | 100 min | 100 min | 100 min | 100 min | 100 min | 100 min | 100 min |

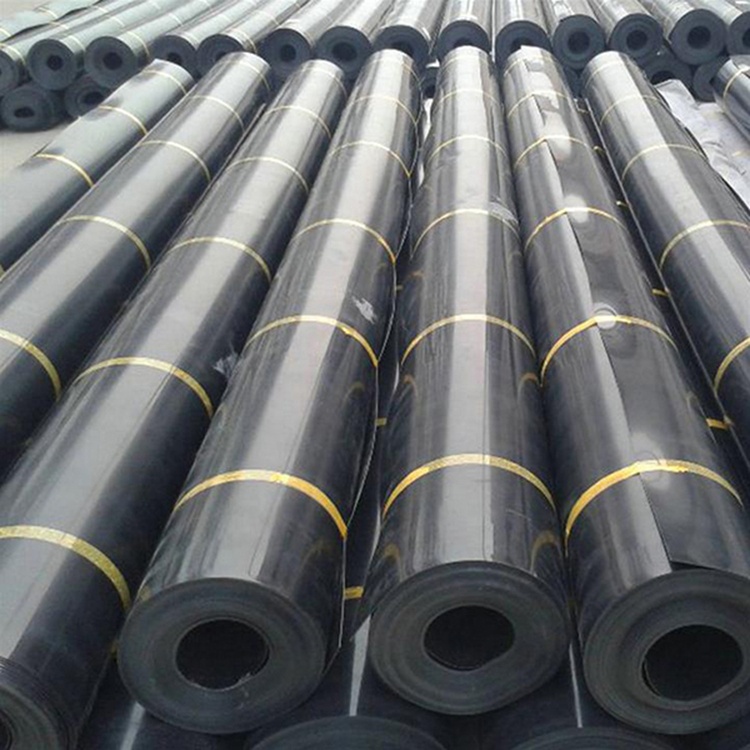

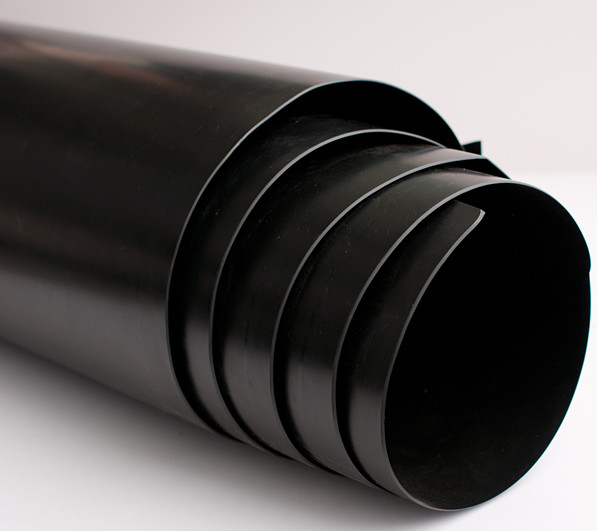

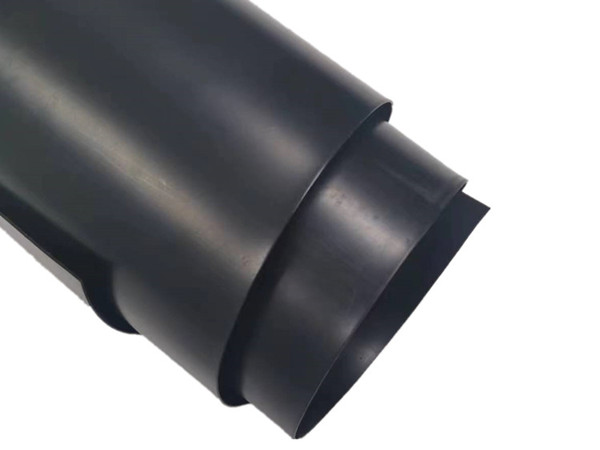

HDPE geomembrane plastic packaging

Equipment of High Quality Good anti-seepage performance HDPE geomembrane

Usage Scenarios of High Quality Good anti-seepage performance HDPE geomembrane

HDPE Geomembrane Technical Parameter (GRI GM13 ASTM Standard) | ||||||||

Spec Properties | Test | GMS0.5 | GMS0.75 | GMS1.0 | GMS1.25 | GMS1.5 | GMS2.0 | GMS2.5 |

Thickness | D5199 | 0.5mm | 0.75mm | 1.00mm | 1 .25mm | 1.50mm | 2.00mm | 2.50mm |

Density (≥ g/cc) | D1505 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 |

Tensile Properties | D6693 Type IV | 8 kN/m 14 kN/m 12% 700% | 11 kN/m | 15 kN/m | 18 kN/m | 22 kN/m 40 kN/m 12% 700% | 29kN/m 53 KN/m 12% 700% | 37kN/m 67kN/m 12% 700% |

Tear Resistance (≥) | D 1004 | 64N | 93N | 125 N | 156N | 187N | 249 N | 311 N |

Puncture Resistance(≥) | D 4833 | 160N | 240N | 320 N | 400 N | 480N | 640 N | 800 N |

Stress Crack Resistance (≥) | D 5397 | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr |

Carbon Black Content | D 1603 | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% |

Carbon Black Dispersion | D 5596 | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) |

Oxidative Induction Time(OIT)(≥) (a)Standard OIT ——or—— | D 3895 D 5885 | 100 min | 100 min | 100 min | 100 min | 100 min | 100 min | 100 min |