Warp-knitted Composite Geomembrane

Warp-knitted composite geomembrane- It is a new kind of geotechnical fabric made of artificial fiber (or glass fiber) as a reinforcing cloth and compounded with a composite Geomembrane.

The warp-knitted composite geomembrane is exclusive from the standard geomembrane. Its largest characteristic is that the intersection of warp and weft is now not curved, and every is in a straight state. Bind the two firmly with a binding wire, which can be synchronized evenly throughout the board, face up to exterior forces, and distribute stress. When the exterior pressure is utilized to tear the material, the yarn will acquire alongside the preliminary crack to enlarge the tear resistance.

Warp-knitted Composite Geomembrane

When warp knitting is combined, the warp knitting binding thread is used to many times tour between the warp, weft yarn and the fiber layer of the geomembrane, so that the three are knitted as one. Therefore, the warp-knitted composite geomembrane no longer solely has the traits of excessive tensile power and low elongation, however additionally has the water-resistant overall performance of geomembrane. Therefore, the warp-knitted composite geomembrane is a type of anti-seepage fabric with the features of reinforcement, isolation and protection. It is a high-level utilized geotechnical composite fabric in the world today

.Product specification:

Thickness: 0.3-3mm; Width: 4-8m size in accordance to person requirements.

Features:

High tensile strength, low elongation, uniform vertical and horizontal deformation, excessive tear strength, splendid put on resistance, and sturdy water resistance.

Application:

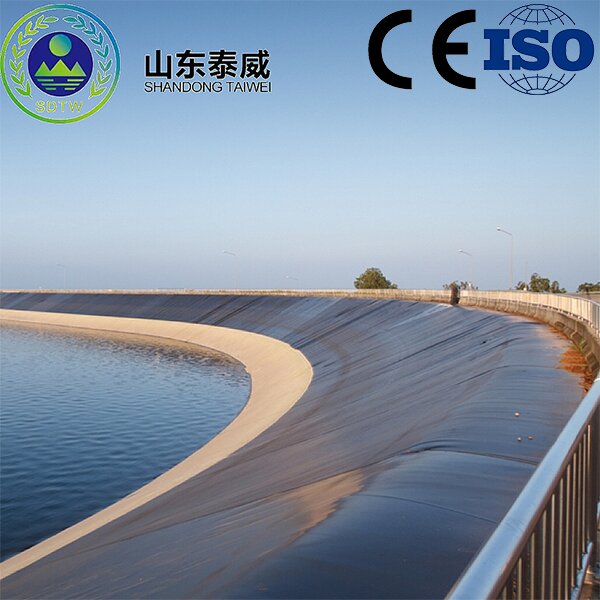

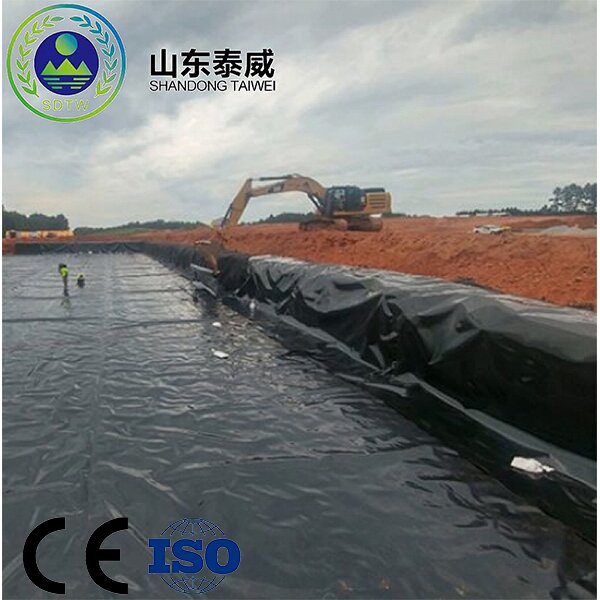

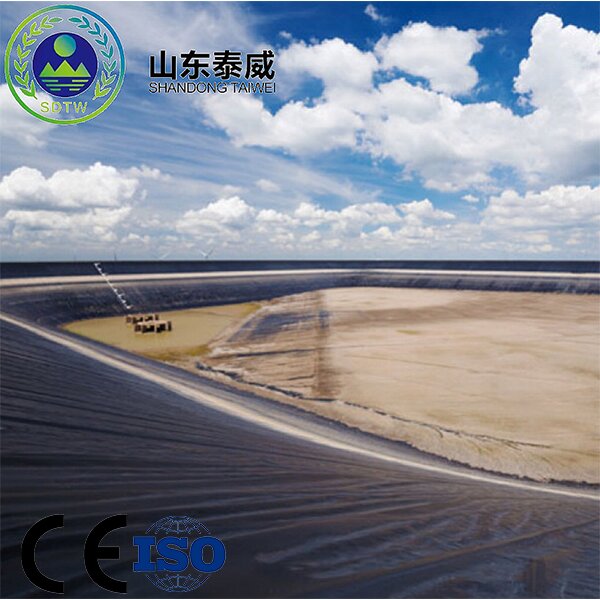

The warp-knitted composite strengthened water resistant geotextile has awesome water resistance, sturdiness and protection. Can be extensively used in railways, highways, sports activities halls, dams, hydraulic structures, tunnels, coastal tidal flats, reclamation, environmental safety and different projects.

Product Implementation Standards: America GRI GM-13 Standard

HDPE Geomembrane Technical Parameter (GRI GM13 ASTM Standard) | ||||||||

Spec Properties | Test | GMS0.5 | GMS0.75 | GMS1.0 | GMS1.25 | GMS1.5 | GMS2.0 | GMS2.5 |

Thickness | D5199 | 0.5mm | 0.75mm | 1.00mm | 1 .25mm | 1.50mm | 2.00mm | 2.50mm |

Density (≥ g/cc) | D1505 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 |

Tensile Properties | D6693 Type IV | 8 kN/m 14 kN/m 12% 700% | 11 kN/m | 15 kN/m | 18 kN/m | 22 kN/m 40 kN/m 12% 700% | 29kN/m 53 KN/m 12% 700% | 37kN/m 67kN/m 12% 700% |

Tear Resistance (≥) | D 1004 | 64N | 93N | 125 N | 156N | 187N | 249 N | 311 N |

Puncture Resistance(≥) | D 4833 | 160N | 240N | 320 N | 400 N | 480N | 640 N | 800 N |

Stress Crack Resistance (≥) | D 5397 | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr |

Carbon Black Content | D 1603 | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% |

Carbon Black Dispersion | D 5596 | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) |

Oxidative Induction Time(OIT)(≥) (a)Standard OIT ——or—— | D 3895 D 5885 | 100 min | 100 min | 100 min | 100 min | 100 min | 100 min | 100 min |

Packing of Warp-knitted Composite Geomembrane

Equipment of Warp-knitted Composite Geomembrane

Usage Scenarios of Warp-knitted Composite Geomembrane

Company Profile

Our business enterprise has mechanical equipment, technical personnel and a large manufacturing team. The annual manufacturing of geotextiles is extra than 30 million rectangular meters, and the composite geomembrane is greater than 10 million rectangular meters. The employer will adhere to the working precept of "integrity-based, gratitude first", make pals from all over the world, cooperate and win-win, and are seeking for frequent development.

HDPE Geomembrane Technical Parameter (GRI GM13 ASTM Standard) | ||||||||

Spec Properties | Test | GMS0.5 | GMS0.75 | GMS1.0 | GMS1.25 | GMS1.5 | GMS2.0 | GMS2.5 |

Thickness | D5199 | 0.5mm | 0.75mm | 1.00mm | 1 .25mm | 1.50mm | 2.00mm | 2.50mm |

Density (≥ g/cc) | D1505 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 |

Tensile Properties | D6693 Type IV | 8 kN/m 14 kN/m 12% 700% | 11 kN/m | 15 kN/m | 18 kN/m | 22 kN/m 40 kN/m 12% 700% | 29kN/m 53 KN/m 12% 700% | 37kN/m 67kN/m 12% 700% |

Tear Resistance (≥) | D 1004 | 64N | 93N | 125 N | 156N | 187N | 249 N | 311 N |

Puncture Resistance(≥) | D 4833 | 160N | 240N | 320 N | 400 N | 480N | 640 N | 800 N |

Stress Crack Resistance (≥) | D 5397 | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr |

Carbon Black Content | D 1603 | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% |

Carbon Black Dispersion | D 5596 | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) |

Oxidative Induction Time(OIT)(≥) (a)Standard OIT ——or—— | D 3895 D 5885 | 100 min | 100 min | 100 min | 100 min | 100 min | 100 min | 100 min |