Staple Fiber Needle Punched PET Geotextile Drainage Fabric

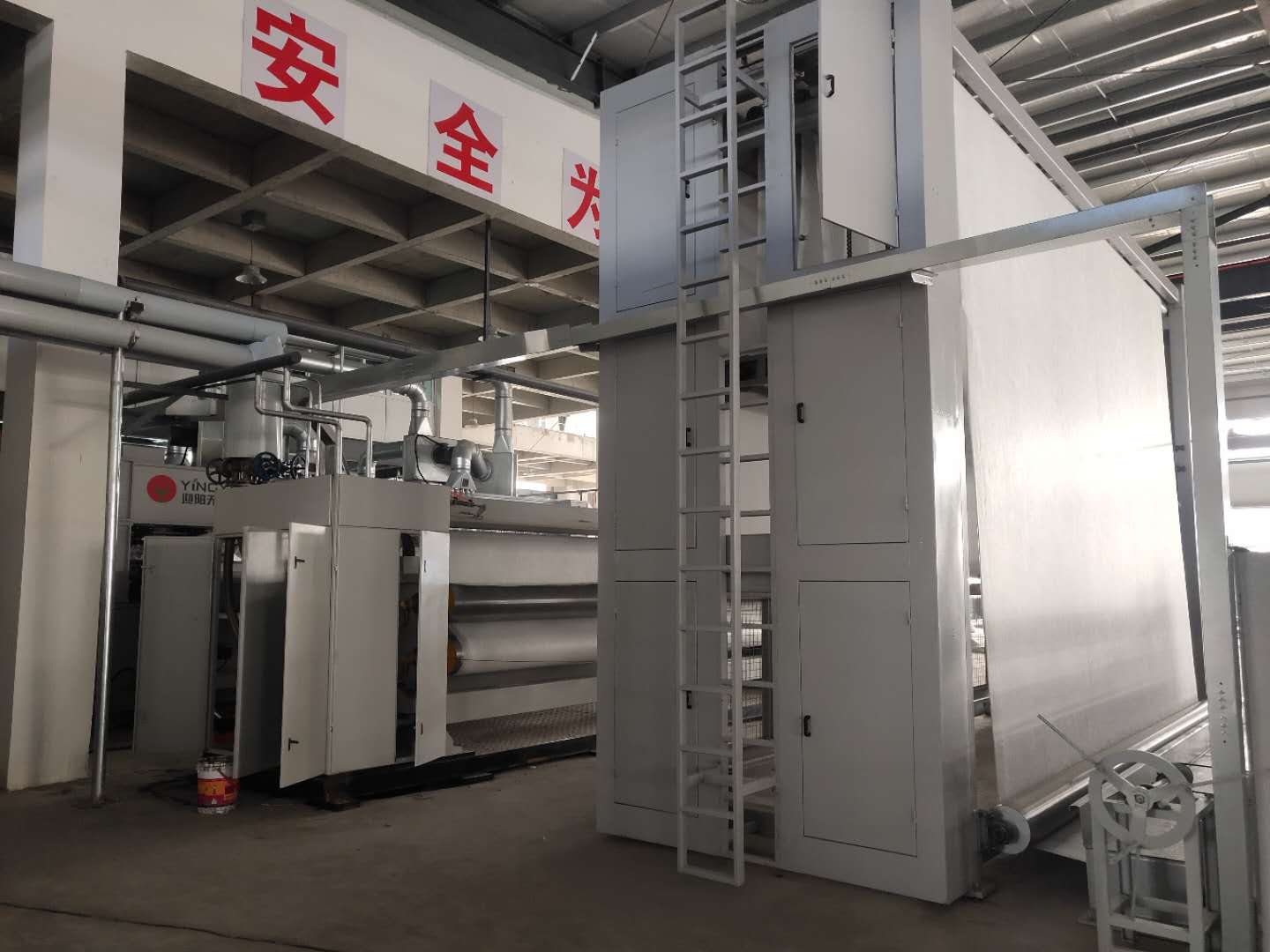

Staple Fiber Needle Punched PET Geotextile Drainage Fabric -Staple-fiber needle-punched nonwoven geotextiles are made into cloth-like fabrics through the production processes of non-woven production equipment, such as opening, carding, messy (short fibers are intertwined with each other), web laying (standardized entanglement and fixation), and needle punching.

●Material: PET fiber

●Color: white, black, gray

●Length: 50m-100m

●Width: 0.5-6m

●Certificate: CE/ISO9001

●Type: Acupuncture

Staple Fiber Needle Punched PET Geotextile Drainage Fabric

PET non-woven geotextiles have good anti-seepage and corrosion resistance characteristics, so that geotextiles are widely used in railways, highways, tunnels, and coastal tidal flat projects. Short-filament geotextiles can be used as reinforcement materials for railway roads and airport runway foundations Reinforcing material for road construction in swampy areas; it can also be used as thermal insulation material to prevent frost and frost.

Product Features:

The surface is rough and not easy to slide. When laying, the rough side of the surface after special treatment is facing upwards to increase the friction coefficient and increase the bonding force of the surface layer to prevent being rolled up and damaged by the wheels during construction, and at the same time, it can inhibit the slippage of vehicles and paver on the cloth ;

Convenient storage and transportation: due to light weight, it can be packaged according to certain requirements, and transportation, storage and construction are very convenient.

Anti-ultraviolet, anti-freeze, anti-chemical corrosion and anti-biological damage;

Easy construction and good application effect. Generally, the fiber filaments of geotextiles are easily lifted by vehicle tires, causing hanging threads, and even being rolled up in severe cases, causing displacement and structural damage of geotextiles.

Application:

The Staple Fiber Needle Punched PET Geotextile Drainage Fabric is mainly characterized by relatively high strength, which can last for a long time in soil with different pH and acid water;

Function:

The water permeability is relatively good, and it has a good water seepage function, because there are gaps in the behavior;

Reverse filtration and drainage: Short fiber geotextile mainly replaces the traditional material gravel layer in the aspect of reverse filtration and drainage. The drainage capacity of the geotextile is directly proportional to the thickness of the geotextile. Generally speaking, the thicker the thickness, the better the drainage capacity of the geotextile.

The filter layer of the initial upstream dam face of the ash storage dam or tailings dam, and the filter layer of the drainage system in the backfill soil of the retaining wall.

Geotextile isolation layer between highway, airport, railway ballast and artificial rockfill and foundation.

Specifications

Staple Fiber Needled Non-woven Geotextile Technical Specifications ( GB/T17638-1998) | |||||||||||||

No. | Item | Specifications | Note | ||||||||||

100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 800 | |||

1 | Unit area mass deviation | -8 | -8 | -8 | -8 | -7 | -7 | -7 | -7 | -6 | -6 | -6 |

|

2 | Thickness mm≥ | 0.9 | 1.3 | 1.7 | 2.1 | 2.4 | 2.7 | 3.0 | 3.3 | 3.6 | 4.1 | 5.0 | |

3 | Width deviation | -0.5 | |||||||||||

4 | Breaking strength | 2.5 | 4.5 | 6.5 | 8.0 | 9.5 | 11 | 12.5 | 14.0 | 16.0 | 19.0 | 25.0 | Vertical and horizontal |

5 | Elongation at break % | 20-100 | |||||||||||

6 | CBR bursting strength | 0.3 | 0.6 | 0.8 | 1.2 | 1.4 | 1.8 | 2.1 | 2.4 | 2.7 | 3.2 | 4.0 |

|

7 | Equivalent aperture | 0.07-0.2 |

| ||||||||||

8 | Vertical permeability coefficient | K*(10-1~10-3) | K=1.0-9.9 | ||||||||||

9 | Tear strength | 0.08 | 0.12 | 0.16 | 0.20 | 0.24 | 0.28 | 0.33 | 0.38 | 0.42 | 0.46 | 0.6 | Vertical and horizontal |

Packing of Staple Fiber Needle Punched PET Geotextile Drainage Fabric

You can freely choose PE film or PP woven bag for outer packaging, and there are paper tubes of different sizes inside the product for you to choose freely.

FAQ

Q: Are you trading company or manufacturer?

A: We are a manufacturer, and we also have our own foreign trade department.

Q: What's your payment terms?

A: Payment: 30% deposit paid by T/T with confirming order, 70% balance paid by T/T before delivery.

Q: Is custom design accepted?

A: Yes, we welcome customized designs.

Q: Can I get a cheaper price?

A: Favorable discount will be given if the quantity you need is large.

Q: Do you provide samples? Is it free or extra?

A: Yes, we can provide samples for free, but do not pay for shipping.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. If the goods are not in stock, it is 15-20 days, it is based on quantity.

Staple Fiber Needled Non-woven Geotextile Technical Specifications ( GB/T17638-1998) | |||||||||||||

No. | Item | Specifications | Note | ||||||||||

100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 800 | |||

1 | Unit area mass deviation | -8 | -8 | -8 | -8 | -7 | -7 | -7 | -7 | -6 | 6 | -6 |

|

2 | Thickness mm≥ | 0.9 | 1.3 | 1.7 | 2.1 | 2.4 | 2.7 | 3.0 | 3.3 | 3.6 | 4.1 | 5.0 | |

3 | Width deviation | -0.5 | |||||||||||

4 | Breaking strength | 2.5 | 4.5 | 6.5 | 8.0 | 9.5 | 11 | 12.5 | 14.0 | 16.0 | 19.0 | 25.0 | Vertical and horizontal |

5 | Elongation at break % | 20-100 | |||||||||||

6 | CBR bursting strength | 0.3 | 0.6 | 0.8 | 1.2 | 1.4 | 1.8 | 2.1 | 2.4 | 2.7 | 3.2 | 4.0 |

|

7 | Equivalent aperture | 0.07-0.2 |

| ||||||||||

8 | Vertical permeability coefficient | K*(10-1~10-3) | K=1.0-9.9 | ||||||||||

9 | Tear strength | 0.08 | 0.12 | 0.16 | 0.20 | 0.24 | 0.28 | 0.33 | 0.38 | 0.42 | 0.46 | 0.6 | Vertical and horizontal |