PP/PET short fiber geotextile for highway construction construction

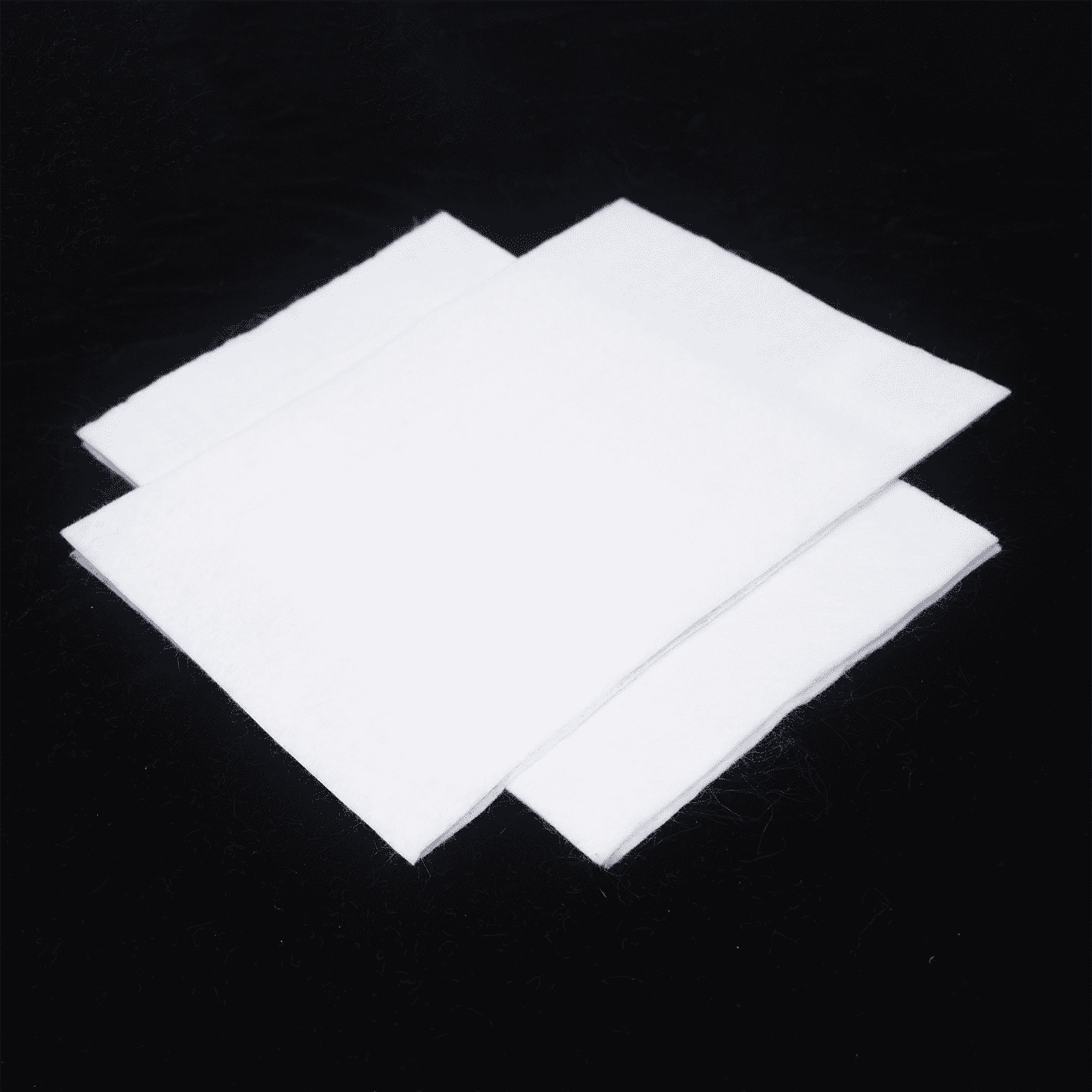

Spunbonded nonwoven

Material: PET/PP

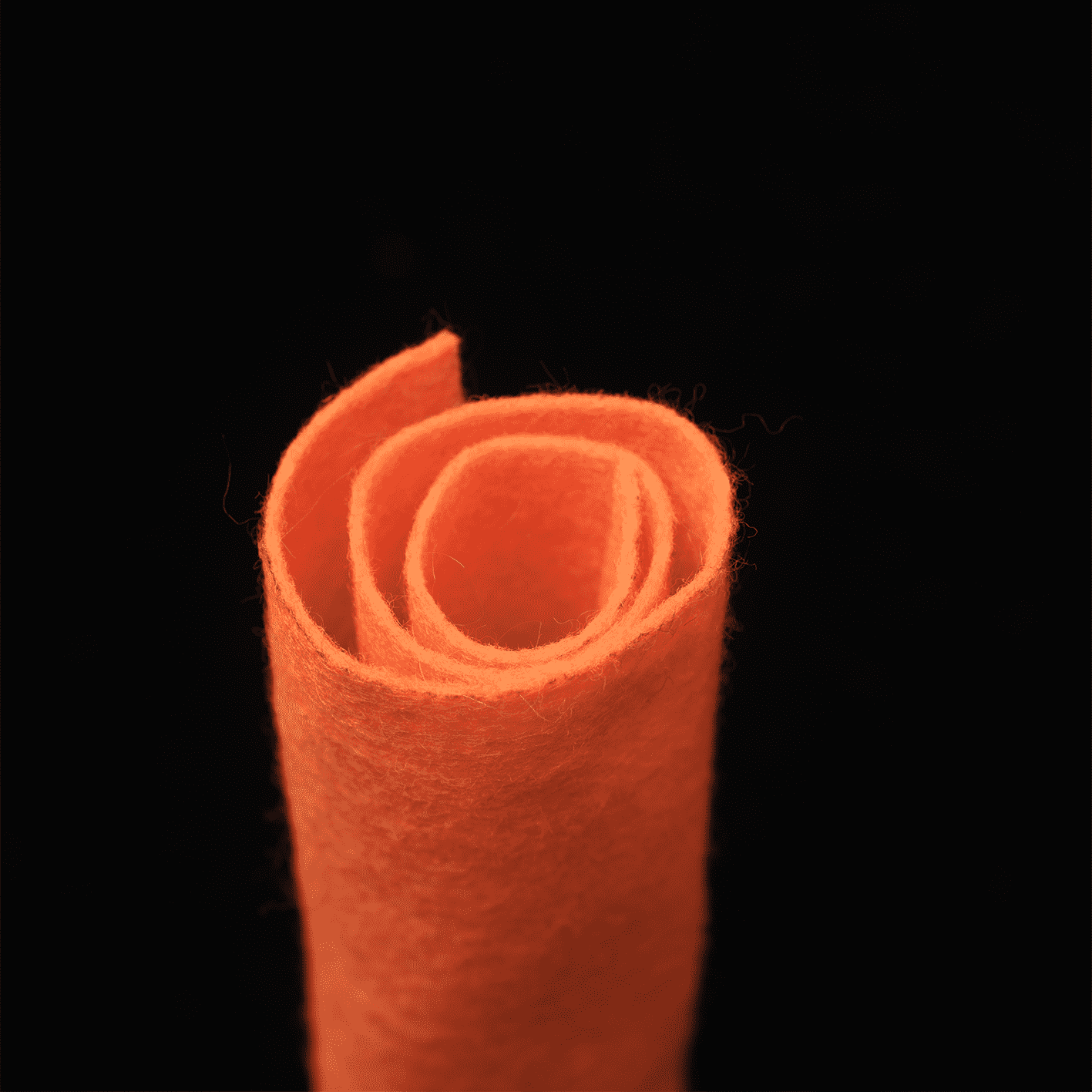

Colors: white, black, green, orange, personalized for statistical coloring

Specification: 100g-800g

Length: 50-200m

Certificate: CE/ISO9001

Support personalized hues and width lengths. Please inform purchaser carrier if there are any different necessities

PP/PET short fiber geotextile for highway construction construction

Product introduction;

Short Fiber Geotextile Fabric is a premium synthetic material made from short fibers, designed to enhance soil properties and provide unmatched stability. With its advanced composition and unique characteristics, this fabric is an essential tool for civil engineers, landscapers, and construction professionals.

One of the key advantages of short fiber geotextile Fabric is its exceptional strength and durability. Its robust construction allows it to withstand heavy loads and constant pressure, providing long-lasting reinforcement to soil structures. Whether it's a road, embankment, or retaining wall, this fabric ensures stability and prevents soil erosion, even in challenging environmental conditions.

Product characteristics;

1.One of the main advantages of geotextile fabric is its ability to provide stability to soil under various environmental conditions. Whether you are dealing with weak soils, high water levels, or intense traffic load, this product can effectively reinforce the ground and prevent erosion by distributing stress and limiting the soil movement.

2.Additionally, geotextile fabric acts as an excellent filter, allowing water to flow through freely while trapping sediments and preventing their migration. It helps in managing water drainage in areas like retaining walls, driveways, and agricultural fields, ensuring proper moisture control and preventing waterlogged soil problems.

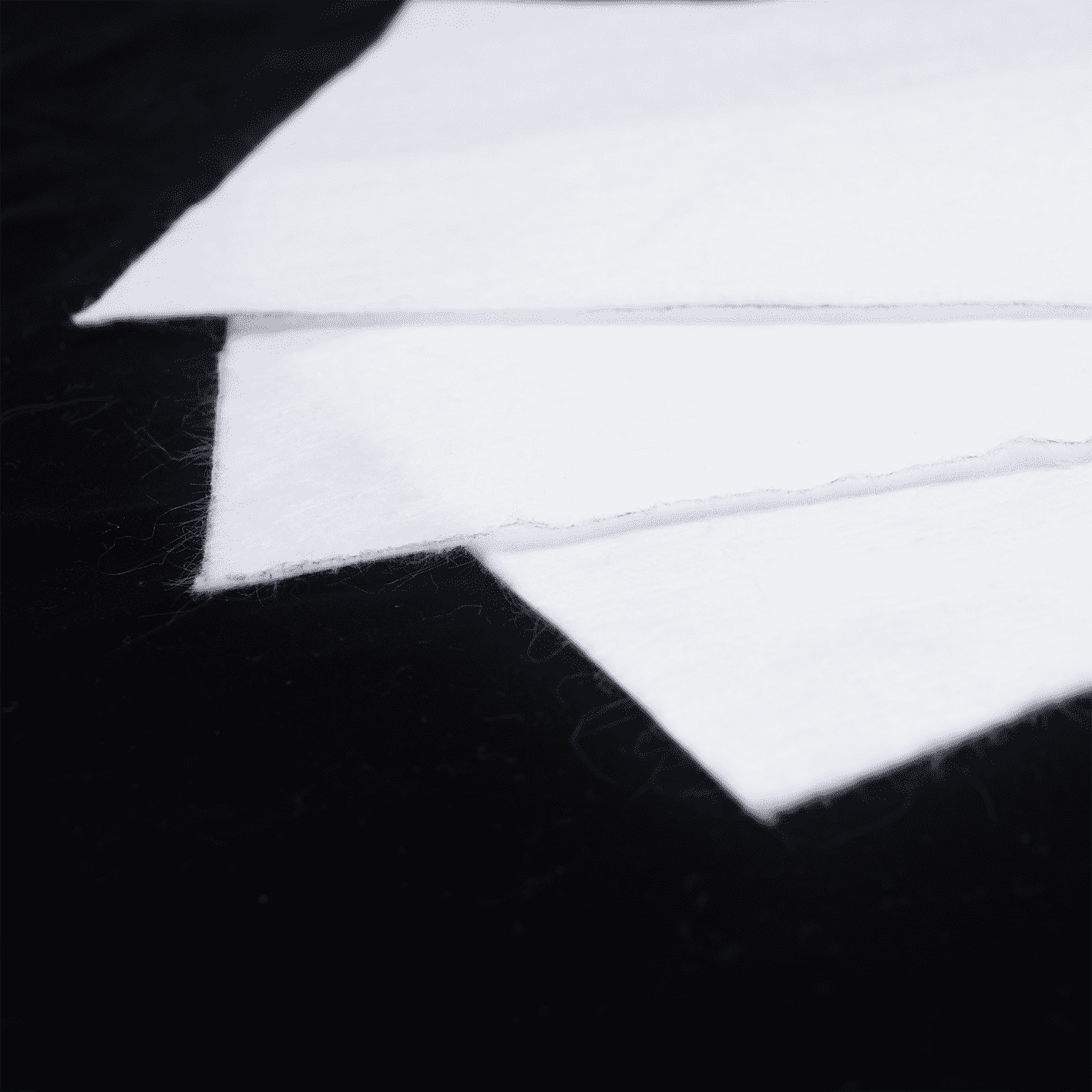

3.Additionally, the lightweight and flexible nature of Short Fiber Geotextile Fabric facilitates easy installation and reduces labor and time expenses. Its versatility allows for seamless integration into various projects, including erosion control, land reclamation, stormwater management, and more. With its exceptional performance and hassle-free installation, this fabric significantly enhances the productivity and efficiency of any soil-related endeavor.

Application scope;

1.Road and Pavement Construction: Geotextile fabric is used in road and pavement construction to improve soil stability, distribute load-bearing capacity, and prevent the mixing of aggregate layers. It helps to reinforce weak soils, increase the lifespan of roads, and reduce maintenance costs.

2.Retaining Wall Systems: Geotextile fabric is utilized in retaining wall systems to prevent soil erosion and improve drainage. It acts as a separator between the backfill soil and the drainage system, providing stability and preventing soil movement.

3.Landfill and Waste Containment: Geotextile fabric plays a vital role in landfill and waste containment applications. It acts as a barrier by preventing the leakage of contaminants into the surrounding environment. It also assists in proper drainage and filtration of waste materials.

4.Shoreline and Coastal Protection: Geotextile fabric is used in coastal and shoreline protection projects to prevent erosion, stabilize embankments, and enhance the natural habitat. It provides a cost-effective solution for erosion control and minimizes the impact of wave action on coastal areas.

5.Drainage Systems: Geotextile fabric is widely used in drainage systems to filter and separate soil particles from water. It improves water flow, reduces the risk of clogging, and ensures effective drainage in applications such as agricultural fields, sports fields, and roadways.

6.Landscape and Garden Design: Geotextile fabric is utilized in landscape and garden design to prevent weed growth, retain moisture, and provide stability to soil. It acts as a protective layer and allows for proper water infiltration, promoting healthy plant growth.

7.Erosion Control: Geotextile fabric is an effective erosion control measure in slopes and embankments. It prevents soil erosion by stabilizing the soil structure, reducing water velocity, and promoting the growth of vegetation.

Specifications

Staple Fiber Needled Non-woven Geotextile Technical Specifications ( GB/T17638-1998) | |||||||||||||

No. | Item | Specifications | Note | ||||||||||

100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 800 | |||

1 | Unit area mass deviation | -8 | -8 | -8 | -8 | -7 | -7 | -7 | -7 | -6 | -6 | -6 |

|

2 | Thickness mm≥ | 0.9 | 1.3 | 1.7 | 2.1 | 2.4 | 2.7 | 3.0 | 3.3 | 3.6 | 4.1 | 5.0 | |

3 | Width deviation | -0.5 | |||||||||||

4 | Breaking strength | 2.5 | 4.5 | 6.5 | 8.0 | 9.5 | 11 | 12.5 | 14.0 | 16.0 | 19.0 | 25.0 | Vertical and horizontal |

5 | Elongation at break % | 20-100 | |||||||||||

6 | CBR bursting strength | 0.3 | 0.6 | 0.8 | 1.2 | 1.4 | 1.8 | 2.1 | 2.4 | 2.7 | 3.2 | 4.0 |

|

7 | Equivalent aperture | 0.07-0.2 |

| ||||||||||

8 | Vertical permeability coefficient | K*(10-1~10-3) | K=1.0-9.9 | ||||||||||

9 | Tear strength | 0.08 | 0.12 | 0.16 | 0.20 | 0.24 | 0.28 | 0.33 | 0.38 | 0.42 | 0.46 | 0.6 | Vertical and horizontal |

Packing of Top Quality Nonwoven Polypropylene Geotextile Price

You can freely choose PE film or PP woven bag for outer packaging, and there are paper tubes of different sizes inside the product for you to choose freely.

Staple Fiber Needled Non-woven Geotextile Technical Specifications ( GB/T17638-1998) | |||||||||||||

No. | Item | Specifications | Note | ||||||||||

100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 800 | |||

1 | Unit area mass deviation | -8 | -8 | -8 | -8 | -7 | -7 | -7 | -7 | -6 | 6 | -6 |

|

2 | Thickness mm≥ | 0.9 | 1.3 | 1.7 | 2.1 | 2.4 | 2.7 | 3.0 | 3.3 | 3.6 | 4.1 | 5.0 | |

3 | Width deviation | -0.5 | |||||||||||

4 | Breaking strength | 2.5 | 4.5 | 6.5 | 8.0 | 9.5 | 11 | 12.5 | 14.0 | 16.0 | 19.0 | 25.0 | Vertical and horizontal |

5 | Elongation at break % | 20-100 | |||||||||||

6 | CBR bursting strength | 0.3 | 0.6 | 0.8 | 1.2 | 1.4 | 1.8 | 2.1 | 2.4 | 2.7 | 3.2 | 4.0 |

|

7 | Equivalent aperture | 0.07-0.2 |

| ||||||||||

8 | Vertical permeability coefficient | K*(10-1~10-3) | K=1.0-9.9 | ||||||||||

9 | Tear strength | 0.08 | 0.12 | 0.16 | 0.20 | 0.24 | 0.28 | 0.33 | 0.38 | 0.42 | 0.46 | 0.6 | Vertical and horizontal |