Environmental protection reinforcement river dam seepage prevention Composite Geotextile

Environmental protection reinforcement river dam seepage preventionComposite Geotextile -With a width of 6.2 meters, it is the widest composite geotextile in China. It has immoderate puncture resistance, big friction coefficient, acceptable getting older resistance, sizeable differ of environmental temperature and extraordinary drainage resistance. It is terrific for water conservancy, chemical engineering, construction, traffic, subway, tunnel, garbage disposal net web site and different initiatives

Material: PET

Color: White

Film thickness: 0.1-1.0mm

Specification: 100g-800g

Length: 50-100m

Certificate: CE/ISO9001

Environmental protection reinforcement river dam seepage preventionComposite Geotextile

Product use;

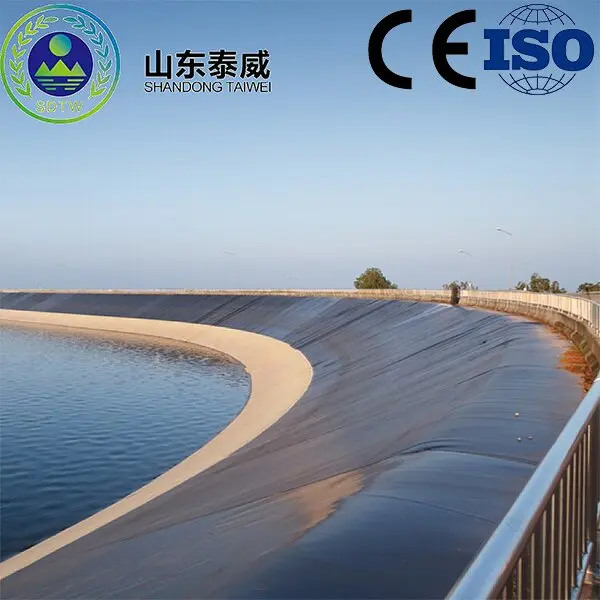

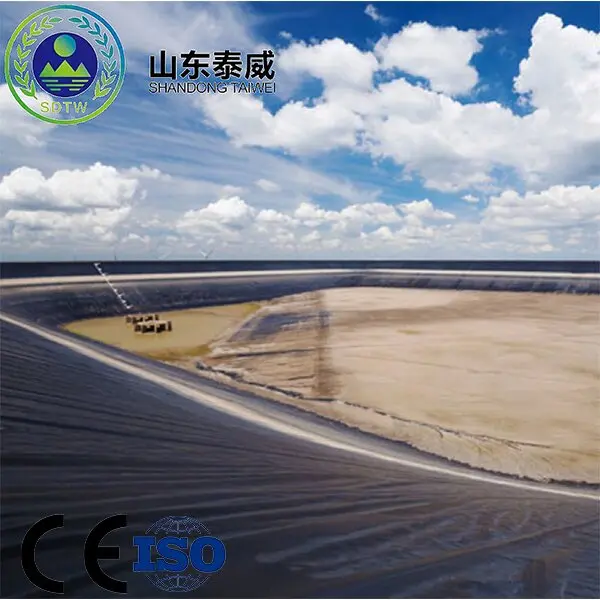

Environmental protection reinforcement river dam seepage preventionComposite Geotextile,Special use for pond Composite Geotextile Function: seepage prevention, isolation use: earth dam, rockfill dam, masonry dam, unfold stress concrete dam; Horizontal anti-seepage cowl in the embankment, dam front, vertical anti-seepage layer as the foundation; Tailings DAMS, sewage reservoirs and reservoir areas; Construction cofferdam; The software program of large-scale software program application software of river channel and liquid storage pool Composite Geomembrane performs a defending property in the ecological environment. Can restrict the avenue cost, prolong the existence of the carrier, put an provide up to the avenue reflection cracks, difficult ground, inconvenient sliding, accessible construction, particular good affect

Good bodily and mechanical properties

Environmental protection reinforcement river dam seepage preventionComposite Geotextile,Excellent water permeability and warmness resistance composite geotextile, hydraulic dam engineering composite geotextile, seepage proof isolation composite geotextile as the shield layer of geomembrane, so that the tightly guarded closed layer is no longer damaged. In order to prevent UV publicity and beautify anti-aging performance, embedding method is a right method. HDPE geomemofilm linings are excellent for massive functions requiring UV and ozone resistance, chemical resistance or immoderate extraordinary installation. Commonly used in landfill and mining applications, the product is delivered in large rolls 7 meters giant and is thermally welded on internet web page with the useful resource of trained technicians to furnish a immoderate quality, examined licensed installation.Construction advice

Environmental protection reinforcement river dam seepage preventionComposite Geotextile,Can restrict the avenue cost, prolong the existence of the carrier, put an end to the avenue reflection cracks, hard ground, inconvenient sliding, on hand construction, proper sensible have an effect on Composite Geotextilebroadly speaking replaces the considerable material gravel layer in the issue of reverse filtration and drainage. The drainage performance of the geotextile is at as quickly as proportional to the thickness of the geotextile. Generally speaking, the thicker the thickness, the larger the drainage performance of the geotextile.

Product implementation standards:

| Composite Geotextile Technical Specification | ||||||||||

| Item | Index | |||||||||

| 1 | Nominal breaking strength / ( kN / m ) | 5 | 7.5 | 10 | 12 | 14 | 16 | 18 | 20 | |

| 2 | Longitudinal and transverse rupture strength /( kN / m )≥ | 5.0 | 7.5 | 10 | 12 | 14 | 16 | 18 | 20 | |

| 3 | Vertical and horizontal standard strength corresponding to elongation /% | 30-100 | ||||||||

| 4 | CBR bursting strength /kN ≥ | 1.1 | 1.5 | 1.9 | 2.2 | 2.5 | 2.8 | 3.0 | 3.2 | |

| 5 | Vertical and horizontal tear strength / kN ≥ | 0.15 | 0.25 | 0.32 | 0.40 | 0.48 | 0.56 | 0.62 | 0.70 | |

| 8 | Vertical Permeability Index / ( cm / s) | According customer needs | ||||||||

| 9 | Width deviation /% | -1.0 | ||||||||

| Item | Membrane thickness/mm | |||||||||

| 0.2 | 0.3 | 0.4 | 0.5 | 0.6 | 0.7 | 0.8 | 1.0 | |||

| Hydrostatic pressure resistance / MPa | 1 fabric with 1 membrane | 0.4 | 0.5 | 0.6 | 0.8 | 1.0 | 1.2 | 1.4 | 1.6 | |

| 2 fabric with 1 membrane | 0.5 | 0.6 | 0.8 | 1.0 | 1.2 | 1.4 | 1.6 | 1.8 | ||

Packing of PET Composite Geotextile

You can freely pick PE movie or PP woven bag for outer packaging, and there are paper tubes of extraordinary sizes interior the product for you to pick freely.

A: The transport time is 7-10 days after receiving the T/T deposit.

Q: How to deal with the pattern fee?

A: We can grant you samples for first-class inspection.

Samples are furnished for free, and clients solely want to pay for the freight.

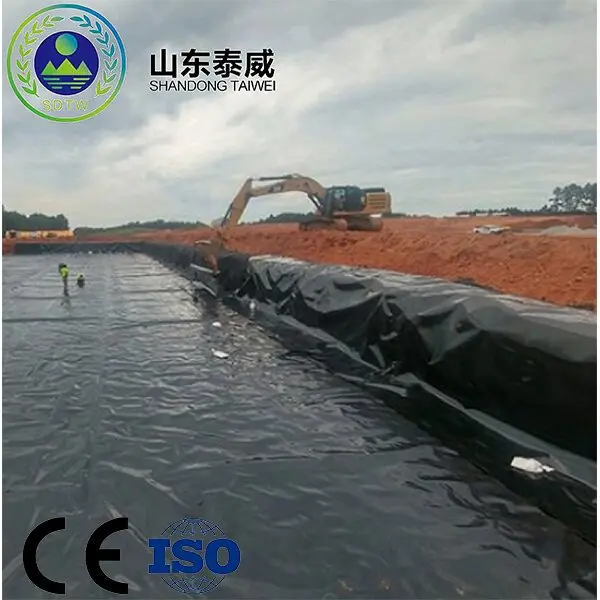

Geomembrane improvement method

Do no longer drag or drag the geomembrane all via transportation to hold away from being stabbed by using way of sharp objects.

1. It ought to extend from the bottom to the immoderate position, do now not pull it too tightly, and go away a margin of 1.50% for partial sinking and stretching. Considering the real nation of affairs of this project, the slope shall be paved from pinnacle to bottom;

| Composite Geomembrane Technical Specification | ||||||||||

| Item | Index | |||||||||

| 1 | Nominal breaking strength / ( kN / m ) | 5 | 7.5 | 10 | 12 | 14 | 16 | 18 | 20 | |

| 2 | Longitudinal and transverse rupture strength /( kN / m )≥ | 5.0 | 7.5 | 10 | 12 | 14 | 16 | 18 | 20 | |

| 3 | Vertical and horizontal standard strength corresponding to elongation /% | 30-100 | ||||||||

| 4 | CBR bursting strength /kN ≥ | 1.1 | 1.5 | 1.9 | 2.2 | 2.5 | 2.8 | 3.0 | 3.2 | |

| 5 | Vertical and horizontal tear strength / kN ≥ | 0.15 | 0.25 | 0.32 | 0.40 | 0.48 | 0.56 | 0.62 | 0.70 | |

| 8 | Vertical Permeability Index / ( cm / s) | According customer needs | ||||||||

| 9 | Width deviation /% | -1.0 | ||||||||

| Item | Membrane thickness/mm | |||||||||

| 0.2 | 0.3 | 0.4 | 0.5 | 0.6 | 0.7 | 0.8 | 1.0 | |||

| Hydrostatic pressure resistance / MPa | 1 fabric with 1 membrane | 0.4 | 0.5 | 0.6 | 0.8 | 1.0 | 1.2 | 1.4 | 1.6 | |

| 2 fabric with 1 membrane | 0.5 | 0.6 | 0.8 | 1.0 | 1.2 | 1.4 | 1.6 | 1.8 | ||

| Composite Geomembrane Technical Specification | ||||||||||

| Item | Index | |||||||||

| 1 | Nominal breaking strength / ( kN / m ) | 5 | 7.5 | 10 | 12 | 14 | 16 | 18 | 20 | |

| 2 | Longitudinal and transverse rupture strength /( kN / m )≥ | 5.0 | 7.5 | 10 | 12 | 14 | 16 | 18 | 20 | |

| 3 | Vertical and horizontal standard strength corresponding to elongation /% | 30-100 | ||||||||

| 4 | CBR bursting strength /kN ≥ | 1.1 | 1.5 | 1.9 | 2.2 | 2.5 | 2.8 | 3.0 | 3.2 | |

| 5 | Vertical and horizontal tear strength / kN ≥ | 0.15 | 0.25 | 0.32 | 0.40 | 0.48 | 0.56 | 0.62 | 0.70 | |

| 8 | Vertical Permeability Index / ( cm / s) | According customer needs | ||||||||

| 9 | Width deviation /% | -1.0 | ||||||||

| Item | Membrane thickness/mm | |||||||||

| 0.2 | 0.3 | 0.4 | 0.5 | 0.6 | 0.7 | 0.8 | 1.0 | |||

| Hydrostatic pressure resistance / MPa | 1 fabric with 1 membrane | 0.4 | 0.5 | 0.6 | 0.8 | 1.0 | 1.2 | 1.4 | 1.6 | |

| 2 fabric with 1 membrane | 0.5 | 0.6 | 0.8 | 1.0 | 1.2 | 1.4 | 1.6 | 1.8 | ||

Related Products

Submitted successfully

We will contact you as soon as possible

Submitted successfully

We will contact you as soon as possible