Highway railway airport Composite Geotextile

Highway railway airport Composite Geotextile -100g-800g composite geotextile is used as the base material, and polyethylene, polyvinyl chloride and specific factors are used as the film. The composite geotextile of nonwoven material has the traits of one cloth one film, two fabric one film, two membranes one fabric and so on. The thickness of the geomembrane is 0.2-1.0mm, which has the feature of isolation, drainage, reinforcement, water seepage prevention, excessive flexibility, corrosion resistance and getting old resistance

Material: PET

Color: White

Film thickness: 0.1-1.0mm

Specification: 100g-800g

Length: 50-100m

Certificate: CE/ISO9001

Highway railway airport Composite Geotextile

Scope of application:

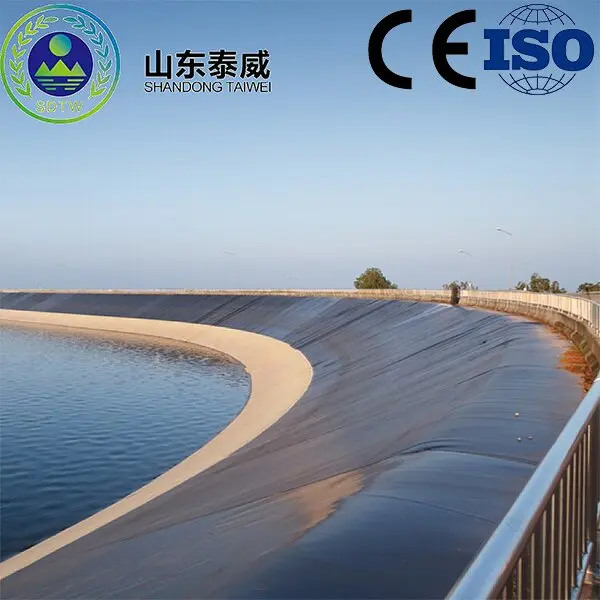

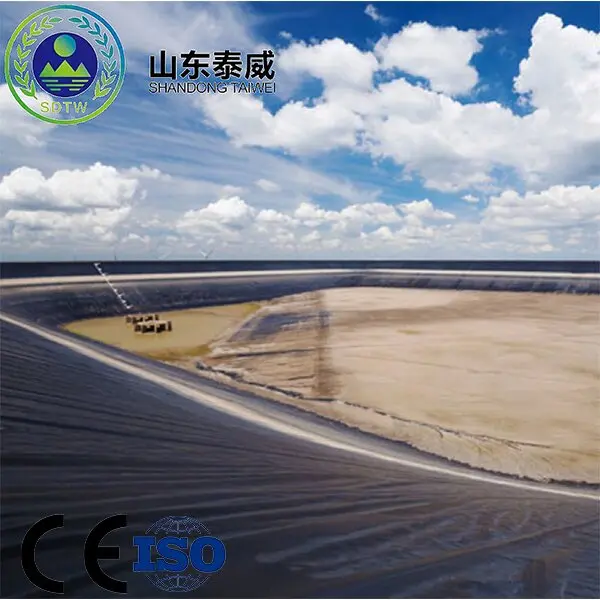

PET Composite Geotextile is an quality tightly closed material, gorgeous for channel, drainage, guard, plain reservoir impervious reinforcement and rockfill dam and exceptional water conservancy and site visitors tunnel purposes

One layer material with one layer membrane: material uint weight100~800gsm, membrane thickness: 0.l~l.0m

Two laver material with one laver membrane: cloth uint weiht 100~400gsm.membrane thickness: 0.2~1.0mm

One layer material with two layer membrane: cloth uint weight 100~800gsm , membrane thickness: 0.1~0.8mm

Product advantage

Highway railway airport Composite Geotextile High strength, due to the use of plastic flat wire, in wet and dry conditions can maintain full strength and elongation.

Corrosion resistance, in different pH levels of soil and water can be long corrosion resistance.

Water permeability is good between the flat wire gap, so it has good water seepage performance.

Good antimicrobial resistance to microorganisms, moth-eaten are not damaged.

Construction is convenient, because the material is light and soft, it is convenient to transport, lay and construction.

More

Good water permeability

Highway railway airport Composite Geotextile Composite geotextile filtration and drainage need to be permeable, so it must have good water permeability.

Product implementation standards:

| Composite Geotextile Technical Specification | ||||||||||

| Item | Index | |||||||||

| 1 | Nominal breaking strength / ( kN / m ) | 5 | 7.5 | 10 | 12 | 14 | 16 | 18 | 20 | |

| 2 | Longitudinal and transverse rupture strength /( kN / m )≥ | 5.0 | 7.5 | 10 | 12 | 14 | 16 | 18 | 20 | |

| 3 | Vertical and horizontal standard strength corresponding to elongation /% | 30-100 | ||||||||

| 4 | CBR bursting strength /kN ≥ | 1.1 | 1.5 | 1.9 | 2.2 | 2.5 | 2.8 | 3.0 | 3.2 | |

| 5 | Vertical and horizontal tear strength / kN ≥ | 0.15 | 0.25 | 0.32 | 0.40 | 0.48 | 0.56 | 0.62 | 0.70 | |

| 8 | Vertical Permeability Index / ( cm / s) | According customer needs | ||||||||

| 9 | Width deviation /% | -1.0 | ||||||||

| Item | Membrane thickness/mm | |||||||||

| 0.2 | 0.3 | 0.4 | 0.5 | 0.6 | 0.7 | 0.8 | 1.0 | |||

| Hydrostatic pressure resistance / MPa | 1 fabric with 1 membrane | 0.4 | 0.5 | 0.6 | 0.8 | 1.0 | 1.2 | 1.4 | 1.6 | |

| 2 fabric with 1 membrane | 0.5 | 0.6 | 0.8 | 1.0 | 1.2 | 1.4 | 1.6 | 1.8 | ||

Packing of PET Composite Geotextile

You can freely pick PE movie or PP woven bag for outer packaging, and there are paper tubes of one-of-a-kind sizes interior the product for you to pick freely.

1. Who are we?

We are a specialised enterprise engaged in the R&D, manufacturing and income of geosynthetics.

Geomembrane use

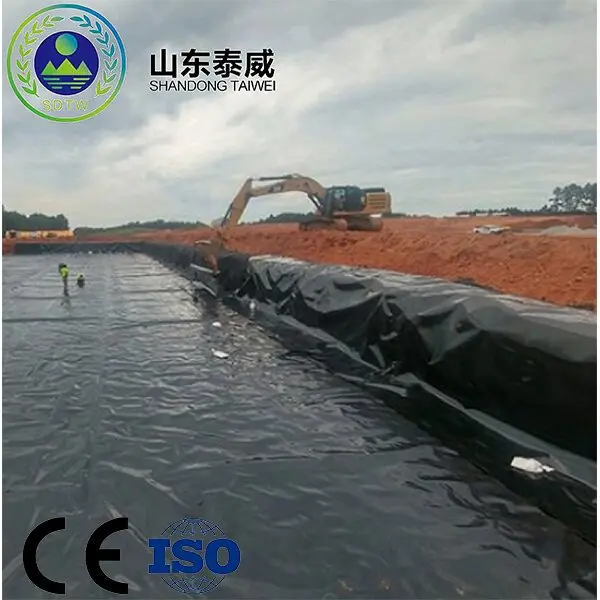

1. Before laying the geomembrane, the corresponding acceptance certificates of the civil engineering want to be obtained.

2. Before decreasing the geomembrane, you have to exactly measure its relevant size, and then limit it in accordance to the true size. Generally, it is now no longer terrific to minimize in accordance to the dimension confirmed in the figure. It have to be numbered one via one and recorded in thing on the first-rate form.

3. When laying the geomembrane, the welding seam want to be minimized, and the raw elements ought to be saved as a lot as plausible below the premise of making certain the quality. At the same time, it is handy to make sure the quality.

4. The overlapping width of the joint between the membrane and the membrane is usually now no longer a whole lot much less than 10cm, and the route of the welding seam is usually equipped parallel to the most slope, that is, geared up alongside the slope direction.

5. Usually in corners and deformed areas, the dimension of the joint ought to be shortened as a total lot as possible. Except for precise requirements, on slopes with a slope accelerated than 1:6, inner 1.5 meters from the pinnacle slope or the stress attention area, try now now not to set up welds.

6. During the laying of the geomembrane, artificial wrinkles have to be avoided. When the temperature is low, it ought to be stretched as a methods as potential and paved flat.

7. After the laying of the geomembrane is completed, taking walks and transferring gear on the flooring of the geomembrane need to be minimized. Anything that can cause injury to the anti-seepage membrane have to no longer be located or carried on the membrane to maintain away from damage to the membrane. cause unintended injury.

| Composite Geomembrane Technical Specification | ||||||||||

| Item | Index | |||||||||

| 1 | Nominal breaking strength / ( kN / m ) | 5 | 7.5 | 10 | 12 | 14 | 16 | 18 | 20 | |

| 2 | Longitudinal and transverse rupture strength /( kN / m )≥ | 5.0 | 7.5 | 10 | 12 | 14 | 16 | 18 | 20 | |

| 3 | Vertical and horizontal standard strength corresponding to elongation /% | 30-100 | ||||||||

| 4 | CBR bursting strength /kN ≥ | 1.1 | 1.5 | 1.9 | 2.2 | 2.5 | 2.8 | 3.0 | 3.2 | |

| 5 | Vertical and horizontal tear strength / kN ≥ | 0.15 | 0.25 | 0.32 | 0.40 | 0.48 | 0.56 | 0.62 | 0.70 | |

| 8 | Vertical Permeability Index / ( cm / s) | According customer needs | ||||||||

| 9 | Width deviation /% | -1.0 | ||||||||

| Item | Membrane thickness/mm | |||||||||

| 0.2 | 0.3 | 0.4 | 0.5 | 0.6 | 0.7 | 0.8 | 1.0 | |||

| Hydrostatic pressure resistance / MPa | 1 fabric with 1 membrane | 0.4 | 0.5 | 0.6 | 0.8 | 1.0 | 1.2 | 1.4 | 1.6 | |

| 2 fabric with 1 membrane | 0.5 | 0.6 | 0.8 | 1.0 | 1.2 | 1.4 | 1.6 | 1.8 | ||

| Composite Geomembrane Technical Specification | ||||||||||

| Item | Index | |||||||||

| 1 | Nominal breaking strength / ( kN / m ) | 5 | 7.5 | 10 | 12 | 14 | 16 | 18 | 20 | |

| 2 | Longitudinal and transverse rupture strength /( kN / m )≥ | 5.0 | 7.5 | 10 | 12 | 14 | 16 | 18 | 20 | |

| 3 | Vertical and horizontal standard strength corresponding to elongation /% | 30-100 | ||||||||

| 4 | CBR bursting strength /kN ≥ | 1.1 | 1.5 | 1.9 | 2.2 | 2.5 | 2.8 | 3.0 | 3.2 | |

| 5 | Vertical and horizontal tear strength / kN ≥ | 0.15 | 0.25 | 0.32 | 0.40 | 0.48 | 0.56 | 0.62 | 0.70 | |

| 8 | Vertical Permeability Index / ( cm / s) | According customer needs | ||||||||

| 9 | Width deviation /% | -1.0 | ||||||||

| Item | Membrane thickness/mm | |||||||||

| 0.2 | 0.3 | 0.4 | 0.5 | 0.6 | 0.7 | 0.8 | 1.0 | |||

| Hydrostatic pressure resistance / MPa | 1 fabric with 1 membrane | 0.4 | 0.5 | 0.6 | 0.8 | 1.0 | 1.2 | 1.4 | 1.6 | |

| 2 fabric with 1 membrane | 0.5 | 0.6 | 0.8 | 1.0 | 1.2 | 1.4 | 1.6 | 1.8 | ||

Related Products

Submitted successfully

We will contact you as soon as possible

Submitted successfully

We will contact you as soon as possible