Non-woven Composite Geotextile

Non-woven Composite Geotextile - Composite Geotextile is used as the substrate, and polyethylene, polyvinyl chloride and extraordinary factors are used asthe membrane. The composite geotextile of the non-woven fabric, has one cloth with one membrane,two cloth with one membrane, two menbrane with one material ect.

Material: PET

Color: White

Film thickness: 0.1-1.0mm

Specification: 100g-800g

Length: 50-100m

Certificate: CE/ISO9001

Scope of application:

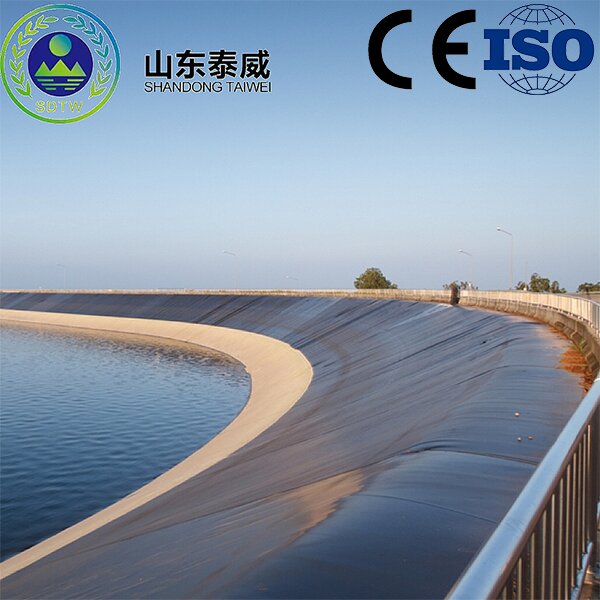

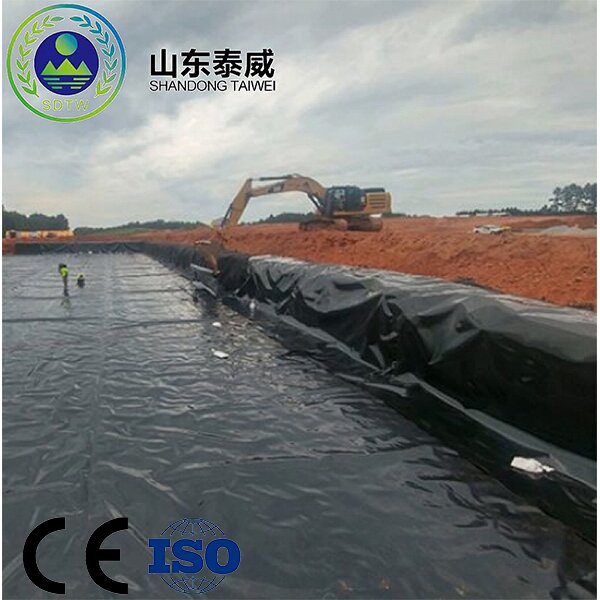

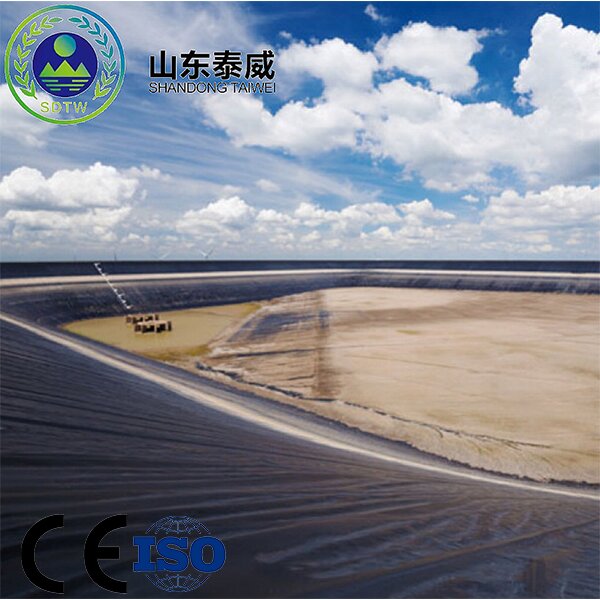

PET Composite Geotextile is an fantastic impenetrable material, terrific for channel, drainage, guard, plain reservoir invulnerable reinforcement and rockfill dam and one-of-a-kind water conservancy and site visitors tunnel functions

Good bodily and mechanical properties

The working surroundings of composite geotextile is harsh, in many instances it is soaked in water or unfold in soil with excessive humidity, so it ought to have accurate hydrolysis resistance and moist mechanical properties.

Resistance to chemicals, corrosion and mildew

Water and earth are very exceptional in nature. Some are alkaline, some are acidic, some include tons salt, and some include quite a number elements, so they should be chemically stable.

Product implementation standards:

| Composite Geotextile Technical Specification | ||||||||||

| Item | Index | |||||||||

| 1 | Nominal breaking strength / ( kN / m ) | 5 | 7.5 | 10 | 12 | 14 | 16 | 18 | 20 | |

| 2 | Longitudinal and transverse rupture strength /( kN / m )≥ | 5.0 | 7.5 | 10 | 12 | 14 | 16 | 18 | 20 | |

| 3 | Vertical and horizontal standard strength corresponding to elongation /% | 30-100 | ||||||||

| 4 | CBR bursting strength /kN ≥ | 1.1 | 1.5 | 1.9 | 2.2 | 2.5 | 2.8 | 3.0 | 3.2 | |

| 5 | Vertical and horizontal tear strength / kN ≥ | 0.15 | 0.25 | 0.32 | 0.40 | 0.48 | 0.56 | 0.62 | 0.70 | |

| 8 | Vertical Permeability Index / ( cm / s) | According customer needs | ||||||||

| 9 | Width deviation /% | -1.0 | ||||||||

| Item | Membrane thickness/mm | |||||||||

| 0.2 | 0.3 | 0.4 | 0.5 | 0.6 | 0.7 | 0.8 | 1.0 | |||

| Hydrostatic pressure resistance / MPa | 1 fabric with 1 membrane | 0.4 | 0.5 | 0.6 | 0.8 | 1.0 | 1.2 | 1.4 | 1.6 | |

| 2 fabric with 1 membrane | 0.5 | 0.6 | 0.8 | 1.0 | 1.2 | 1.4 | 1.6 | 1.8 | ||

Packing of PET Composite Geotextile

You can freely choose PE film or PP woven bag for outer packaging, and there are paper tubes of different sizes inside the product for you to choose freely.

Non-woven Composite Geotextile

Needle-punched non-woven fabric and PE film composite geotextile, the specification is one cloth and one film, two cloth and one film, the maximum width is 4.2 meters. The purpose is anti-seepage, suitable for railways, highways, tunnels, subways, airports and other projects.

| Composite Geomembrane Technical Specification | ||||||||||

| Item | Index | |||||||||

| 1 | Nominal breaking strength / ( kN / m ) | 5 | 7.5 | 10 | 12 | 14 | 16 | 18 | 20 | |

| 2 | Longitudinal and transverse rupture strength /( kN / m )≥ | 5.0 | 7.5 | 10 | 12 | 14 | 16 | 18 | 20 | |

| 3 | Vertical and horizontal standard strength corresponding to elongation /% | 30-100 | ||||||||

| 4 | CBR bursting strength /kN ≥ | 1.1 | 1.5 | 1.9 | 2.2 | 2.5 | 2.8 | 3.0 | 3.2 | |

| 5 | Vertical and horizontal tear strength / kN ≥ | 0.15 | 0.25 | 0.32 | 0.40 | 0.48 | 0.56 | 0.62 | 0.70 | |

| 8 | Vertical Permeability Index / ( cm / s) | According customer needs | ||||||||

| 9 | Width deviation /% | -1.0 | ||||||||

| Item | Membrane thickness/mm | |||||||||

| 0.2 | 0.3 | 0.4 | 0.5 | 0.6 | 0.7 | 0.8 | 1.0 | |||

| Hydrostatic pressure resistance / MPa | 1 fabric with 1 membrane | 0.4 | 0.5 | 0.6 | 0.8 | 1.0 | 1.2 | 1.4 | 1.6 | |

| 2 fabric with 1 membrane | 0.5 | 0.6 | 0.8 | 1.0 | 1.2 | 1.4 | 1.6 | 1.8 | ||

| Composite Geomembrane Technical Specification | ||||||||||

| Item | Index | |||||||||

| 1 | Nominal breaking strength / ( kN / m ) | 5 | 7.5 | 10 | 12 | 14 | 16 | 18 | 20 | |

| 2 | Longitudinal and transverse rupture strength /( kN / m )≥ | 5.0 | 7.5 | 10 | 12 | 14 | 16 | 18 | 20 | |

| 3 | Vertical and horizontal standard strength corresponding to elongation /% | 30-100 | ||||||||

| 4 | CBR bursting strength /kN ≥ | 1.1 | 1.5 | 1.9 | 2.2 | 2.5 | 2.8 | 3.0 | 3.2 | |

| 5 | Vertical and horizontal tear strength / kN ≥ | 0.15 | 0.25 | 0.32 | 0.40 | 0.48 | 0.56 | 0.62 | 0.70 | |

| 8 | Vertical Permeability Index / ( cm / s) | According customer needs | ||||||||

| 9 | Width deviation /% | -1.0 | ||||||||

| Item | Membrane thickness/mm | |||||||||

| 0.2 | 0.3 | 0.4 | 0.5 | 0.6 | 0.7 | 0.8 | 1.0 | |||

| Hydrostatic pressure resistance / MPa | 1 fabric with 1 membrane | 0.4 | 0.5 | 0.6 | 0.8 | 1.0 | 1.2 | 1.4 | 1.6 | |

| 2 fabric with 1 membrane | 0.5 | 0.6 | 0.8 | 1.0 | 1.2 | 1.4 | 1.6 | 1.8 | ||