Anti-seepage Farming HDPE Geomembrane

Anti-seepage Farming HDPE Geomembrane-As a new variety of material, anti-seepage geomembrane for breeding has brilliant anti-seepage, anti-corrosion performance, correct chemical stability, and can be processed in accordance to suitable engineering needs. It has been drastically used in dikes and dams of water conservancy projects.

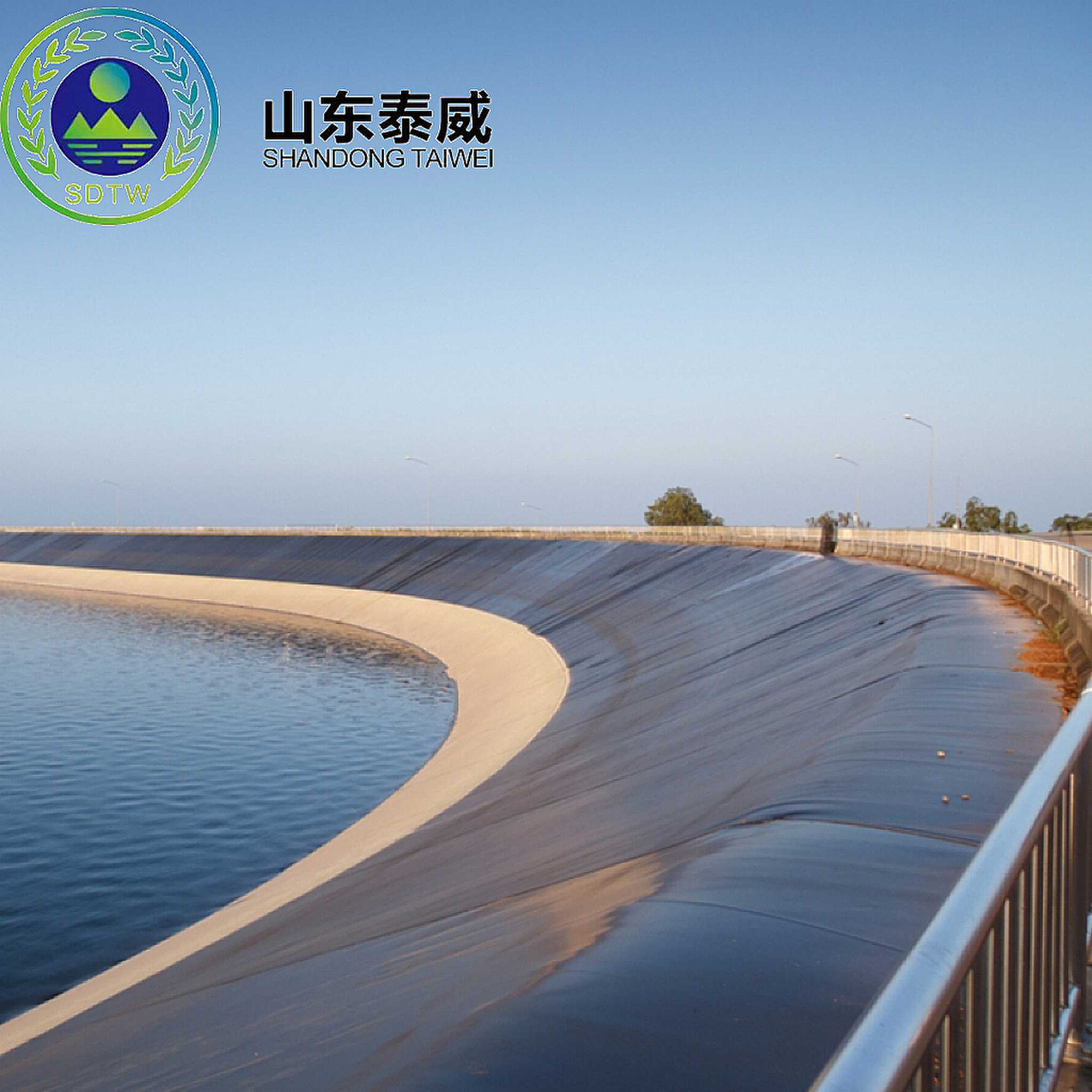

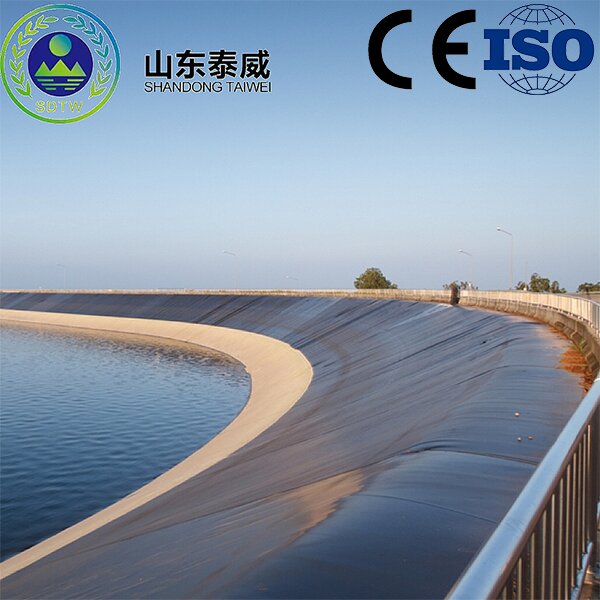

Reservoir anti-seepage, and moreover used as anti-seepage, anti-corrosion, leak-proof, moisture-proof components in channels, reservoirs, sewage pools, swimming pools, housing construction, underground buildings, garbage dumps, environmental engineering, etc.

Anti-seepage Farming HDPE Geomembrane

Anti-seepage Farming HDPE Geomembrane is moreover referred to as high-density polyethylene anti-seepage geomembrane for farming, HDPE anti-seepage geomembrane for farming, HDPE anti-seepage geomembrane for farming is a plastic coil composed of HDPE, and HDPE is a A beautifully crystalline, non-polar thermoplastic resin. The seem of the genuine HDPE is milky white, and the skinny vicinity is translucent to a fantastic extent. PE has outstanding resistance to most domestic and industrial chemicals.

Product specification:

Thickness: 0.3-3mm; Width: 4-8m size in accordance to consumer necessities

Features:

1. Farming anti-seepage geomembrane is a flexible water resistant material with a immoderate anti-seepage coefficient (1×10-17 cm/s);

2. The breeding anti-seepage geomembrane has perfect warmness resistance and cold resistance, and its going for walks environment temperature is immoderate temperature one hundred ten ℃, low temperature -70 ℃;

3. The breeding anti-seepage geomembrane has suited chemical stability, and it is a actual anti-corrosion material that can face up to the corrosion of strong acid, alkali and oil;

4. The breeding anti-seepage geomembrane has immoderate tensile strength, so that it has immoderate tensile energy and can meet the wishes of high-standard engineering projects;

5. The breeding anti-seepage geomembrane has sturdy local weather resistance, strong anti-aging performance, and can be used uncovered for a prolonged time to keep the special performance;

6. The common average overall performance of the cultured anti-seepage geomembrane, HDPE geomembrane has sturdy tensile electrical energy and elongation at break, so that HDPE geomembrane can be used in a range of harsh geological and climatic conditions. Adapt to uneven geological contract and strong strain.

7. The breeding anti-seepage geomembrane adopts pinnacle notch raw plastic and carbon black particles barring any preservatives. HDPE has been used in my us of a to alternate PVC as raw cloth for foods packaging baggage and fresh-keeping films.

Application:

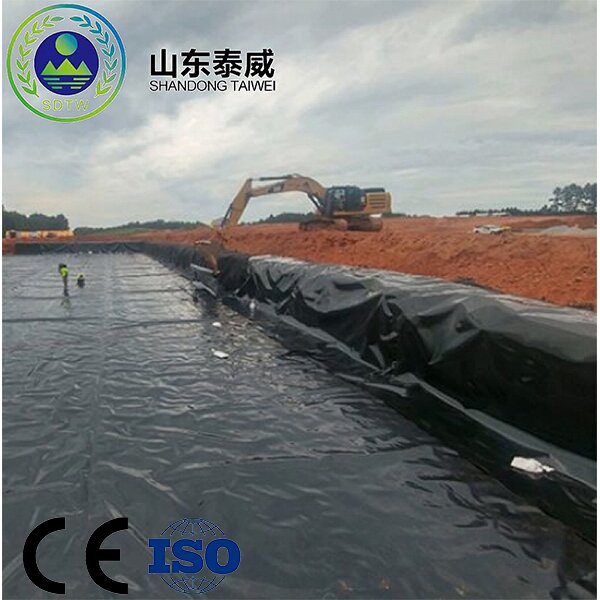

1. Environmental safety and sanitation (such as home waste landfills, sewage treatment, poisonous and hazardous substance remedy plants, unsafe items warehouses, industrial waste, building and blasting waste, etc.)

2. Water conservancy (such as anti-seepage, plugging, reinforcement of rivers, lakes, reservoirs and dams, anti-seepage of canals, vertical core walls, slope protection, etc.)

3. Municipal engineering (subway, underground engineering of constructions and roof cisterns, anti-seepage of roof gardens, lining of sewage pipes, etc.)

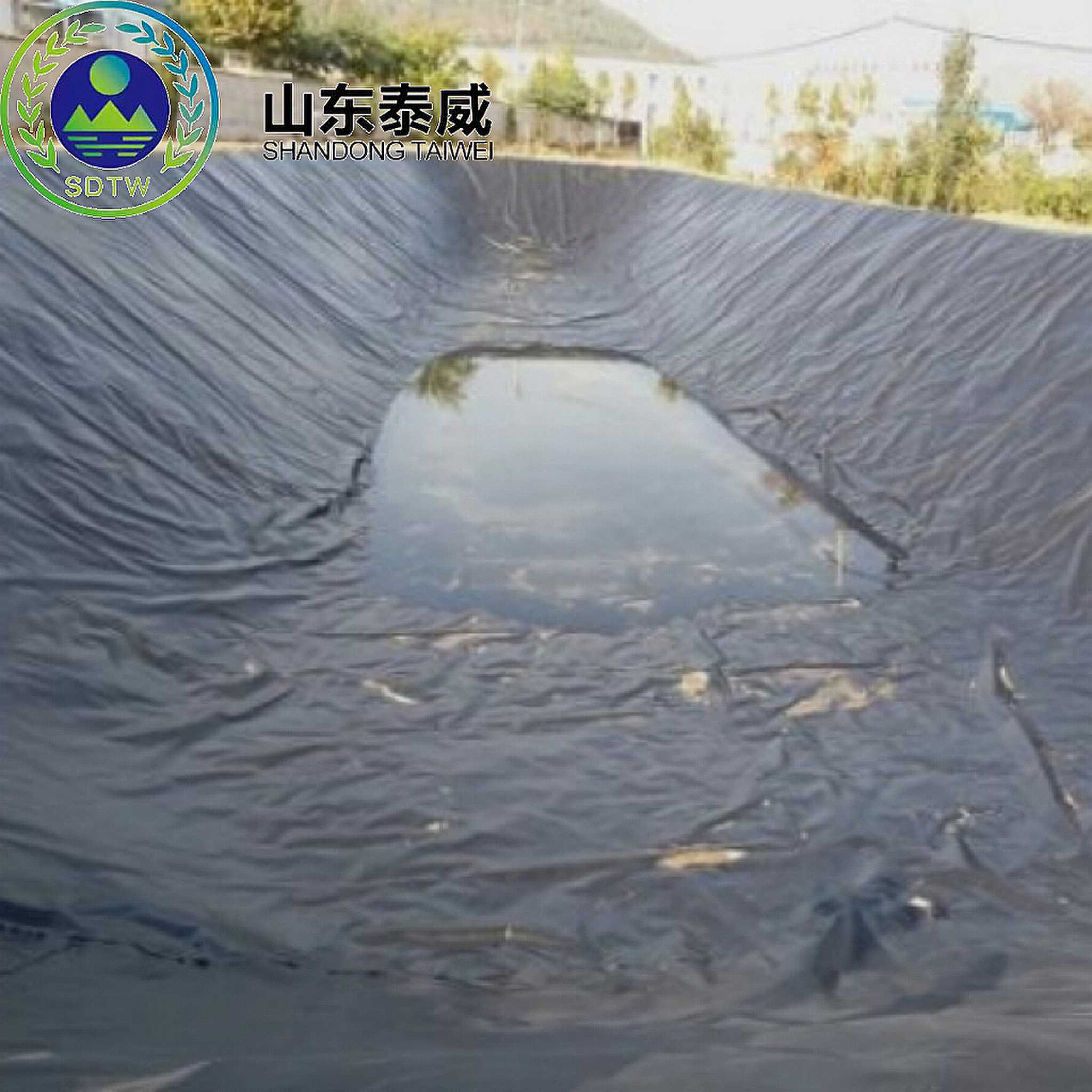

4. Gardens (artificial lakes, ponds, pond linings of golf courses, slope protection, etc.)

5. Petrochemical (chemical plants, oil refineries, anti-seepage of oil storage tanks in gasoline stations, chemical response tanks, internal linings of sedimentation tanks, secondary linings, etc.)

6. Mining enterprise (washing pond, heap leaching pond, ash dump, dissolution pond, sedimentation pond, stockyard, anti-seepage of backside lining of tailings pond, etc.)

7. Agriculture (reservoirs, ingesting water pools, storage ponds, anti-seepage of irrigation systems)

8. Aquaculture enterprise (lining of fish ponds, shrimp ponds, slope safety of sea cucumber rings, etc.)

9. Salt enterprise (salt area crystallization pond, brine pond thatch cover, salt film, salt pond plastic thatch film)

Product Implementation Standards: America GRI GM-13 Standard

HDPE Geomembrane Technical Parameter (GRI GM13 ASTM Standard) | ||||||||

Spec Properties | Test | GMS0.5 | GMS0.75 | GMS1.0 | GMS1.25 | GMS1.5 | GMS2.0 | GMS2.5 |

Thickness | D5199 | 0.5mm | 0.75mm | 1.00mm | 1 .25mm | 1.50mm | 2.00mm | 2.50mm |

Density (≥ g/cc) | D1505 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 |

Tensile Properties | D6693 Type IV | 8 kN/m 14 kN/m 12% 700% | 11 kN/m | 15 kN/m | 18 kN/m | 22 kN/m 40 kN/m 12% 700% | 29kN/m 53 KN/m 12% 700% | 37kN/m 67kN/m 12% 700% |

Tear Resistance (≥) | D 1004 | 64N | 93N | 125 N | 156N | 187N | 249 N | 311 N |

Puncture Resistance(≥) | D 4833 | 160N | 240N | 320 N | 400 N | 480N | 640 N | 800 N |

Stress Crack Resistance (≥) | D 5397 | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr |

Carbon Black Content | D 1603 | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% |

Carbon Black Dispersion | D 5596 | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) |

Oxidative Induction Time(OIT)(≥) (a)Standard OIT ——or—— | D 3895 D 5885 | 100 min | 100 min | 100 min | 100 min | 100 min | 100 min | 100 min |

Packing of Anti-seepage Farming HDPE Geomembrane

Equipment of Anti-seepage Farming HDPE Geomembrane

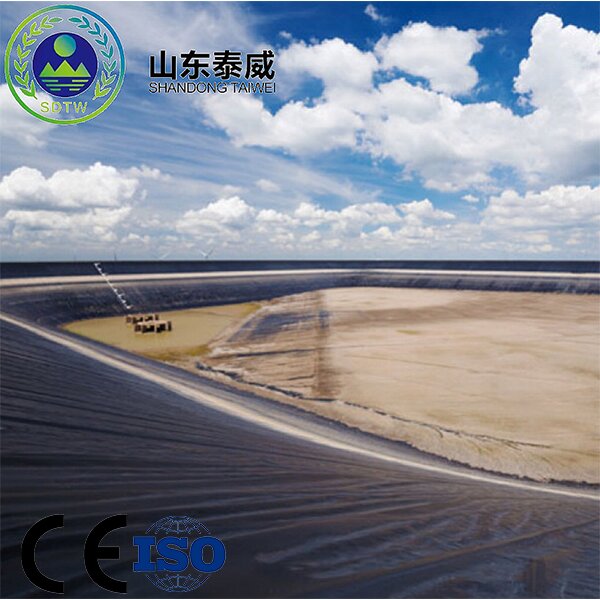

Usage Scenarios of Anti-seepage Farming HDPE Geomembrane

Company Profile

Our agency has mechanical equipment, technical personnel and a large manufacturing team. The annual manufacturing of geotextiles is greater than 30 million rectangular meters, and the composite geomembrane is extra than 10 million rectangular meters. The organization will adhere to the running precept of "integrity-based, gratitude first", make buddies from all over the world, cooperate and win-win, and are trying to find frequent development.

HDPE Geomembrane Technical Parameter (GRI GM13 ASTM Standard) | ||||||||

Spec Properties | Test | GMS0.5 | GMS0.75 | GMS1.0 | GMS1.25 | GMS1.5 | GMS2.0 | GMS2.5 |

Thickness | D5199 | 0.5mm | 0.75mm | 1.00mm | 1 .25mm | 1.50mm | 2.00mm | 2.50mm |

Density (≥ g/cc) | D1505 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 |

Tensile Properties | D6693 Type IV | 8 kN/m 14 kN/m 12% 700% | 11 kN/m | 15 kN/m | 18 kN/m | 22 kN/m 40 kN/m 12% 700% | 29kN/m 53 KN/m 12% 700% | 37kN/m 67kN/m 12% 700% |

Tear Resistance (≥) | D 1004 | 64N | 93N | 125 N | 156N | 187N | 249 N | 311 N |

Puncture Resistance(≥) | D 4833 | 160N | 240N | 320 N | 400 N | 480N | 640 N | 800 N |

Stress Crack Resistance (≥) | D 5397 | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr | 300 hr |

Carbon Black Content | D 1603 | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% |

Carbon Black Dispersion | D 5596 | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) |

Oxidative Induction Time(OIT)(≥) (a)Standard OIT ——or—— | D 3895 D 5885 | 100 min | 100 min | 100 min | 100 min | 100 min | 100 min | 100 min |